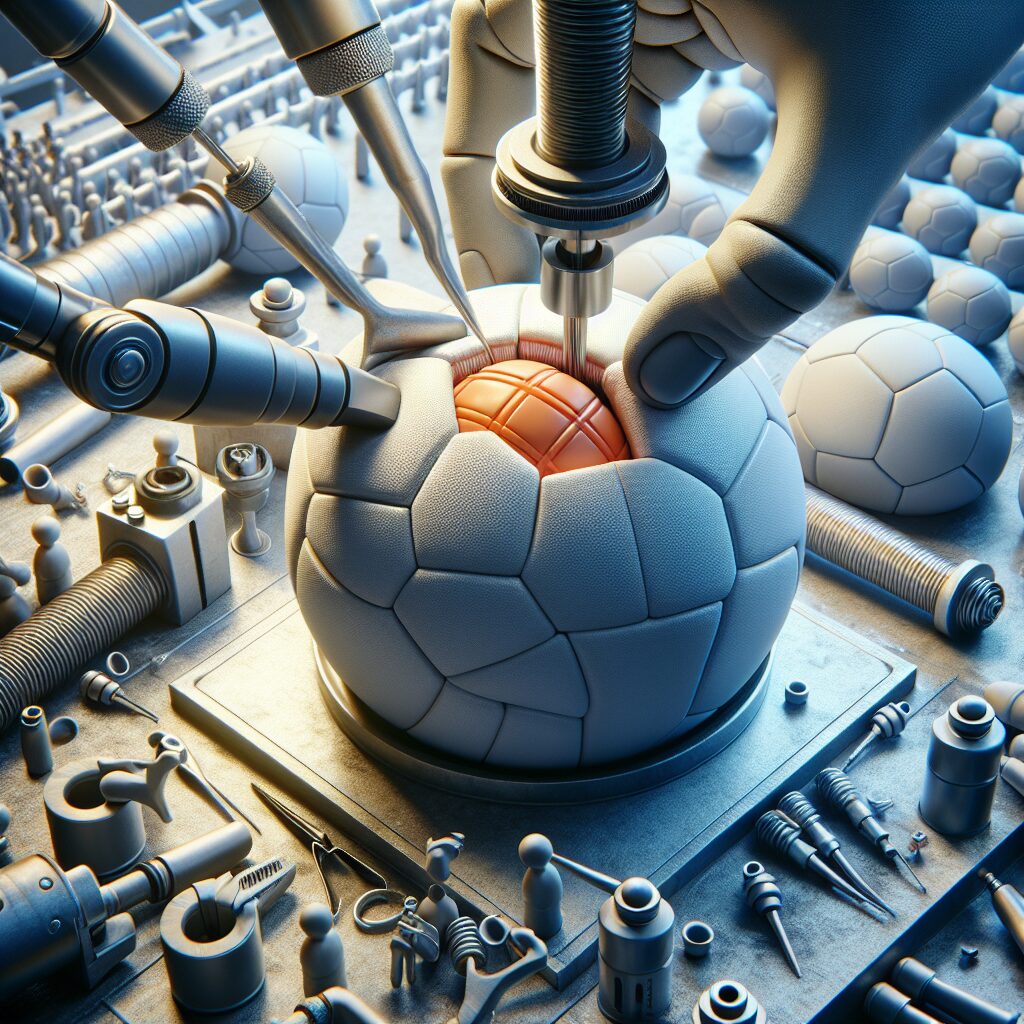

The Crucial Bladder Insertion Process in Ball Making is a significant step that shouldn’t be overlooked. Before delving into the specifics of this process, let’s first define what a bladder is in the context of ball making. A bladder refers to an inflatable, rubber-like object that is inserted into the ball during its manufacturing process. This hollow bladder plays a pivotal role in determining the final shape, bounce, and performance of the ball.

The bladder insertion process is crucial because it directly impacts the quality and characteristics of the ball. One of the key impacts of a well-executed bladder insertion is the consistency of shape. When the bladder is properly inserted, it ensures an even distribution of air pressure within the ball, leading to a perfectly spherical shape. This, in turn, affects the ball’s trajectory and accuracy when in use.

Moving on to the unique features of this process, it is worth mentioning that different types of balls require different bladder materials and designs. For instance, soccer balls may have a latex bladder, while basketballs often incorporate a butyl bladder. This diversity in bladder composition reflects the various demands and specifications of different sports.

With an understanding of the importance and unique aspects of the bladder insertion process, it is crucial to explore the key takeaways that will be discussed further in this article. In the upcoming sections, we will delve into the intricacies of bladder material selection, the impact of bladder shape on ball performance, and the role of proper bladder inflation. These insights will provide a comprehensive understanding of the crucial role the bladder insertion process plays in the manufacturing of high-quality balls. So, let’s dive in and discover the secrets behind the scenes of ball making.

Key Takeaways

1. The bladder insertion process in ball making is a crucial step that involves inflating a rubber bladder inside the ball to create its shape.

2. The process requires skilled technicians who carefully position the bladder and inflate it with compressed air, ensuring it is evenly distributed and centered within the ball.

3. Proper bladder insertion is essential for ensuring the durability and performance of the ball, as any misalignment or unevenness can affect its balance and bounce.

4. Quality control measures are implemented throughout the insertion process, including regular checks for bladder position, inflation pressure, and overall ball shape.

5. Continuous research and advancements in bladder insertion techniques are being pursued to further enhance the consistency and precision of this critical process in ball manufacturing.

What is the SEO Optimized Article Title Question for The Crucial Bladder Insertion Process in Ball Making?

Section 1: Understanding the Crucial Bladder Insertion Process

In the manufacturing process of balls, particularly sports balls like soccer balls, basketballs, etc., the bladder insertion process plays a pivotal role. This section will delve into the step-by-step procedure of the crucial bladder insertion process, highlighting its importance and key considerations.

Section 2: Materials and Equipment Required for Bladder Insertion

In this section, we will discuss the essential materials and equipment needed for a successful bladder insertion process in ball making. From bladders to adhesives and specialized tools, understanding the items required is crucial for ensuring a smooth manufacturing process.

Section 3: Preparing the Ball for Bladder Insertion

Preparing a ball correctly before the bladder insertion is vital to achieve the desired performance and durability. Here, we will explore the preparatory steps involved, such as cleaning the ball surface, massaging the bladder, and examining the ball for potential flaws.

Section 4: Step-by-Step Bladder Insertion Process

Now it’s time to dive deep into the actual bladder insertion process. This section will guide you through each step involved, including creating an opening, inserting the bladder, and securing it firmly in place. Additionally, it will touch upon best practices and troubleshooting tips.

Section 5: Quality Control and Testing

After the bladder is successfully inserted, quality control and testing measures ensure the ball meets the required standards. In this section, we will discuss various quality control tests, such as inflation, weight, and bounce tests, highlighting their significance in determining the ball’s performance.

Section 6: Common Challenges and Solutions

The bladder insertion process is not always free of challenges. In this section, we will address some common issues faced during bladder insertion and provide effective solutions. From bladder leaks to misalignment, understanding how to overcome these challenges is crucial for ensuring a high-quality end product.

Numbered Guides or Tips for the Crucial Bladder Insertion Process:

- What are the key considerations for selecting the right type of bladder for ball making?

- How can you ensure proper alignment of the bladder during insertion?

- What quality control tests should you perform after the bladder insertion?

- How can you fix common issues like bladder leaks or misalignment during the process?

- What are some best practices for achieving optimal results in bladder insertion?

Frequently Asked Questions

1. What is the bladder insertion process in ball making?

The bladder insertion process in ball making refers to the crucial step of inserting a high-quality bladder into the ball’s casing during manufacturing. This bladder helps maintain the ball’s shape, bounce, and overall performance.

2. Why is the bladder insertion process crucial?

The bladder insertion process is crucial because it directly affects the quality and durability of the ball. A proper bladder insertion ensures consistent bounce, optimal air pressure retention, and excellent overall performance.

3. How is the bladder inserted into the ball’s casing?

The bladder is typically inserted into the ball’s casing through a small opening. Manufacturers often use specialized machinery to ensure precise placement of the bladder. The opening is then securely sealed to prevent any air leakage.

4. What materials are used for the bladder?

The bladder is usually made of latex or butyl rubber, both of which offer excellent elasticity and air retention properties. Manufacturers carefully select the type and quality of bladder material based on the desired characteristics of the ball.

5. Can the bladder be replaced if it gets damaged?

In some cases, it is possible to replace the bladder if it gets damaged. However, it requires expertise and specialized tools. It is recommended to contact the manufacturer or a professional for bladder replacement.

6. How does the bladder insertion process affect the ball’s performance?

The bladder insertion process plays a significant role in determining the ball’s performance. Proper insertion ensures consistent balance, shape, and responsiveness. A poorly inserted bladder may result in irregular bounce, deflation issues, or reduced playability.

7. Are there any specific maintenance tips for balls with bladder inserts?

It is essential to follow manufacturer guidelines for maintaining balls with bladder inserts. Avoid exposing the ball to extreme temperatures, sharp objects, or excessive moisture. Proper inflation and storage in a suitable environment can prolong the life of the bladder and maintain optimal performance.

8. How do manufacturers ensure the quality of bladder insertion?

Manufacturers have strict quality control processes in place to ensure the proper insertion of the bladder. These may include thorough inspections, testing the bounce and shape consistency of each ball, and monitoring the overall manufacturing process.

9. Can the bladder insertion process be automated?

Yes, many manufacturers use automated machinery to insert the bladder into balls. This helps ensure consistency, accuracy, and efficiency in the process. Automation reduces the likelihood of human error and improves overall productivity.

10. How can I identify a well-inserted bladder in a ball?

A well-inserted bladder in a ball should result in a smooth and symmetrical shape. The ball should have an even bounce when dropped from a certain height and maintain appropriate air pressure. If you notice irregularities or performance issues, it is advisable to contact the manufacturer for further assistance.

Final Thoughts

The bladder insertion process is a crucial aspect of ball making that directly impacts the ball’s performance and durability. Manufacturers invest substantial efforts and expertise to ensure precise bladder insertion, resulting in high-quality balls with consistent bounce and shape.

Whether for recreational play or professional sports, choosing a ball with a properly inserted bladder is vital. By understanding the importance of this process and following proper maintenance guidelines, players and organizations can maximize the longevity and performance of their sports balls.