Sustainable Materials: A Green Revolution in Ball Fabrication

In today’s rapidly changing world, sustainability has become a key focus for industries across the globe. One such sector that is making notable strides towards a greener future is ball fabrication. Defined as the process of creating spherical objects used in various sports and industrial applications, ball fabrication now leverages sustainable materials to minimize environmental impact. This shift towards sustainable materials has ushered in a green revolution in ball production, with significant implications for the environment and the sports industry alike.

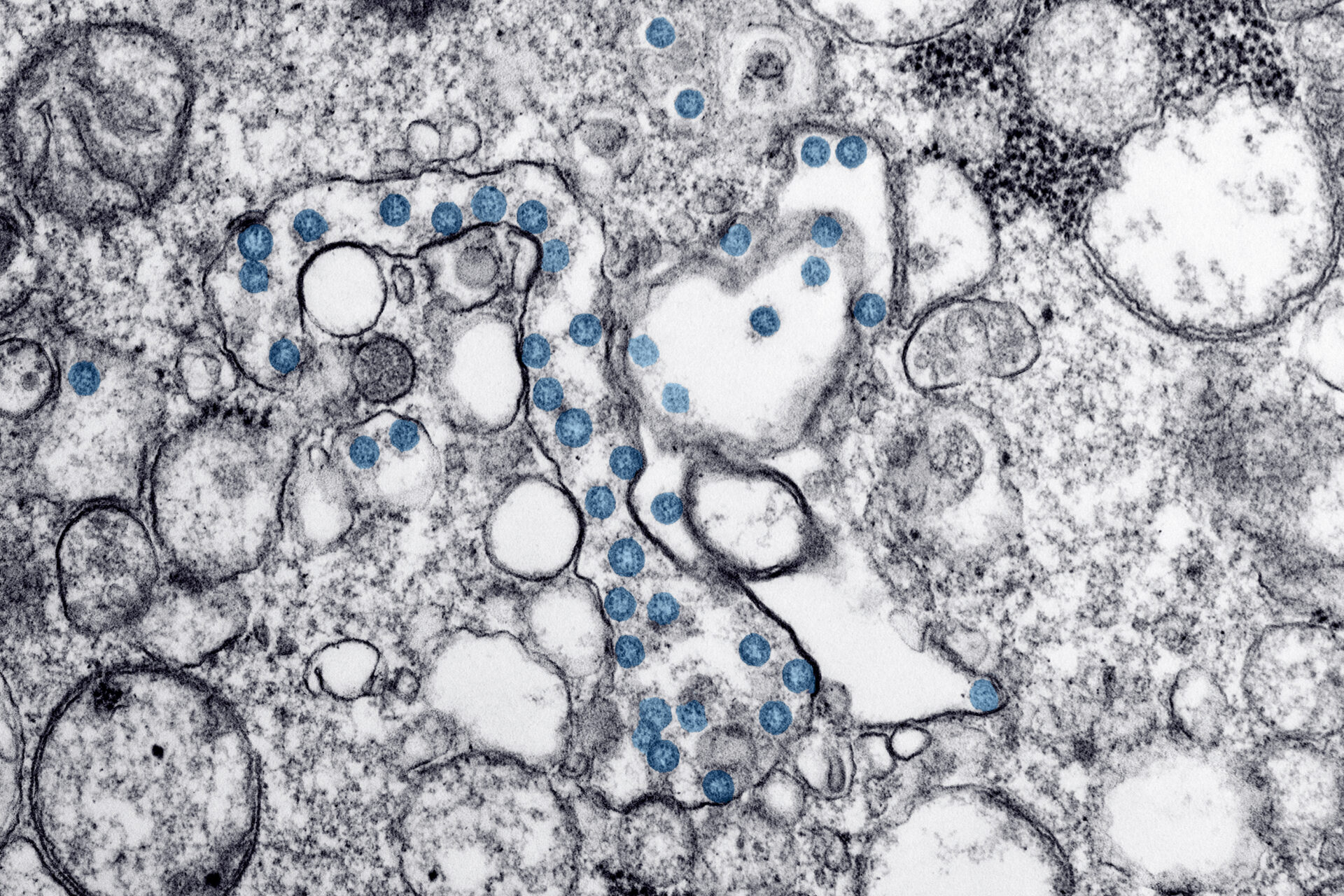

One of the unique features of sustainable materials in ball fabrication is their ability to reduce waste and emissions throughout the manufacturing process. Traditionally, ball production involved the use of non-renewable resources such as synthetic fibers, plastics, and rubber. These materials not only required extensive extraction and processing but also released harmful chemicals into the environment. However, with the advent of sustainable materials like organic cotton, recycled plastics, and natural rubber, the negative environmental consequences associated with ball fabrication are being mitigated. By utilizing these eco-friendly alternatives, manufacturers are not only decreasing their carbon footprint but also promoting a circular economy by reusing materials that would otherwise end up in landfills.

With the rising demand for sustainable products, the adoption of eco-friendly materials in ball fabrication is gaining momentum. The use of recycled plastics, for instance, not only reduces the reliance on fossil fuels but also helps tackle the global plastic waste crisis. Furthermore, organic cotton ensures that the raw material used in ball production is free from harmful pesticides and chemicals, offering a safer and healthier option for both consumers and the environment. As we delve deeper into this article, we will explore the key takeaways of this green revolution in ball fabrication, including the impact on sports performance, the economic viability of sustainable materials, and the future prospects of eco-friendly ball production. Stay tuned to uncover the exciting possibilities that lie ahead in this sustainable revolution.

Key Takeaways

1. Sustainable materials are revolutionizing the fabrication of sports balls by replacing traditional synthetic materials with eco-friendly alternatives.

2. Bio-based materials, such as natural rubber and plant-based polyurethane, are increasingly used in the production of sports balls, reducing the reliance on fossil fuel-derived materials.

3. The use of sustainable materials not only reduces environmental impact but also improves the quality and performance of sports balls, offering durability, enhanced grip, and improved playing experience.

4. Manufacturers are embracing innovation and collaboration to develop sustainable materials that meet the demanding requirements of sports balls while also meeting environmental and social sustainability goals.

5. The shift towards sustainable ball fabrication is driven by consumer demand for environmentally responsible products and the realization that sustainable materials can contribute to a more circular economy.

What are the Benefits of Sustainable Materials in Ball Fabrication?

The Importance of Sustainable Materials

Sustainable materials have become a key component in the revolution of ball fabrication. Not only do they offer environmental benefits, but they also provide economic advantages and improved performance. With the focus on sustainability increasing in various industries, incorporating these materials into ball production has transformed the way we think about sports equipment.

Reducing Environmental Impact

The use of sustainable materials in ball fabrication significantly reduces the environmental footprint of the manufacturing process. Traditional materials like leather or synthetic textiles require large amounts of water, energy, and chemicals during production. In contrast, sustainable materials such as recycled polyester, organic cotton, or natural rubber offer a more eco-friendly alternative.

Enhancing Performance and Durability

Sustainable materials not only benefit the environment but also improve the performance and durability of the balls. Manufacturers are now utilizing innovative technologies to develop sustainable materials that offer the same or even better quality than traditional options. These materials provide enhanced grip, better bounce, and increased durability, making them ideal for professional athletes and sports enthusiasts.

Supporting Ethical and Social Responsibility

Choosing sustainable materials for ball fabrication aligns with ethical and social responsibility values. By opting for materials that are responsibly sourced and produced, manufacturers contribute to fair trade practices, reduce harmful emissions, and support workers’ welfare. This approach promotes a positive image for both the brand and the industry, attracting environmentally conscious consumers.

Collaboration for Sustainable Innovation

The green revolution in ball fabrication has fostered collaborations between manufacturers, researchers, and suppliers to continuously improve sustainable materials. By working together, these stakeholders can exchange knowledge and resources to develop new and innovative materials that are even more sustainable and efficient. This collaborative effort drives the industry forward while minimizing its ecological impact.

Top Tips for Incorporating Sustainable Materials in Ball Fabrication

- Consider using recycled or regenerative materials like recycled polyester or natural rubber.

- Source materials from suppliers with a transparent and ethical supply chain.

- Prioritize energy-efficient manufacturing processes to reduce carbon emissions.

- Opt for eco-friendly packaging options to minimize waste.

- Engage in research and development to discover new sustainable materials and technologies.

- Educate consumers about the benefits of sustainable materials in ball fabrication.

- Collaborate with other industry players to share knowledge and drive sustainable innovation.

- Implement recycling programs for used balls to promote a circular economy.

- Continuously monitor and improve sustainability practices in the entire production chain.

Frequently Asked Questions

1. What are sustainable materials in ball fabrication?

Sustainable materials in ball fabrication refer to materials that are sourced, produced, and disposed of in an environmentally friendly manner. These materials are designed to have a minimal impact on the planet, both in terms of resource depletion and pollution.

2. Why is the use of sustainable materials important in ball fabrication?

Using sustainable materials in ball fabrication is important because it helps reduce the environmental footprint of the manufacturing process. It minimizes the extraction of non-renewable resources, reduces energy consumption, and minimizes waste generation.

3. What types of sustainable materials can be used in ball fabrication?

There are various sustainable materials that can be used in ball fabrication, such as recycled rubber, organic cotton, natural latex, and biodegradable polyurethane. These materials are chosen for their eco-friendly properties and their ability to perform well in sports applications.

4. Are sustainable materials as durable as traditional materials?

Yes, sustainable materials used in ball fabrication can be just as durable as traditional materials. Manufacturers have developed advanced technologies and production processes to ensure that sustainable materials meet the required standards for durability and performance.

5. How do sustainable materials contribute to reducing carbon emissions?

Sustainable materials contribute to reducing carbon emissions in ball fabrication by minimizing the use of fossil fuels in production and transportation. They require less energy to manufacture and transport, resulting in lower greenhouse gas emissions compared to conventional materials.

6. Are sustainable materials more expensive than traditional materials for ball fabrication?

Sustainable materials may initially be more expensive than traditional materials due to their eco-friendly production processes and sourcing methods. However, as the demand for sustainable materials increases and economies of scale come into play, the prices are likely to become more comparable.

7. How do companies ensure the authenticity of sustainable materials used in ball fabrication?

Companies ensure the authenticity of sustainable materials by obtaining certifications or using trusted suppliers who have established eco-friendly practices. They may also conduct internal audits and quality control measures to ensure that the materials they use meet the required sustainability standards.

8. Can recycled materials be used in ball fabrication?

Yes, recycled materials can be used in ball fabrication. For example, recycled rubber from old tires can be utilized to create the outer covering of sports balls. This not only reduces waste but also reduces the need for new raw materials.

9. Do sustainable materials affect the performance of balls?

No, sustainable materials are carefully selected and engineered to ensure they meet the required performance standards. Manufacturers conduct extensive testing to ensure that balls made from sustainable materials perform just as well as those made from traditional materials.

10. What impact does the use of sustainable materials have on the local communities?

The use of sustainable materials in ball fabrication can have positive impacts on local communities. It promotes sustainable livelihoods by supporting eco-friendly industries and reducing environmental pollution. Additionally, the demand for sustainable materials can create job opportunities and contribute to local economic growth.

Final Thoughts

The adoption of sustainable materials in ball fabrication marks a significant step towards a greener future. By choosing materials that are kinder to the planet, manufacturers are actively reducing their environmental impact and promoting sustainable practices throughout the industry.

As consumers, we play a vital role in driving this green revolution. By consciously choosing products made from sustainable materials, we can support the efforts of manufacturers and encourage the wider adoption of eco-friendly practices. Together, we can contribute to a more sustainable and environmentally conscious sporting world.