Sustainable manufacturing is a topic that has gained increasing attention in recent years, especially in industries such as ball production. This manufacturing process focuses on minimizing the environmental impact while still ensuring high-quality products are created. From the use of eco-friendly materials to the implementation of energy-efficient practices, sustainable manufacturing in ball production has emerged as a trailblazer in the industry.

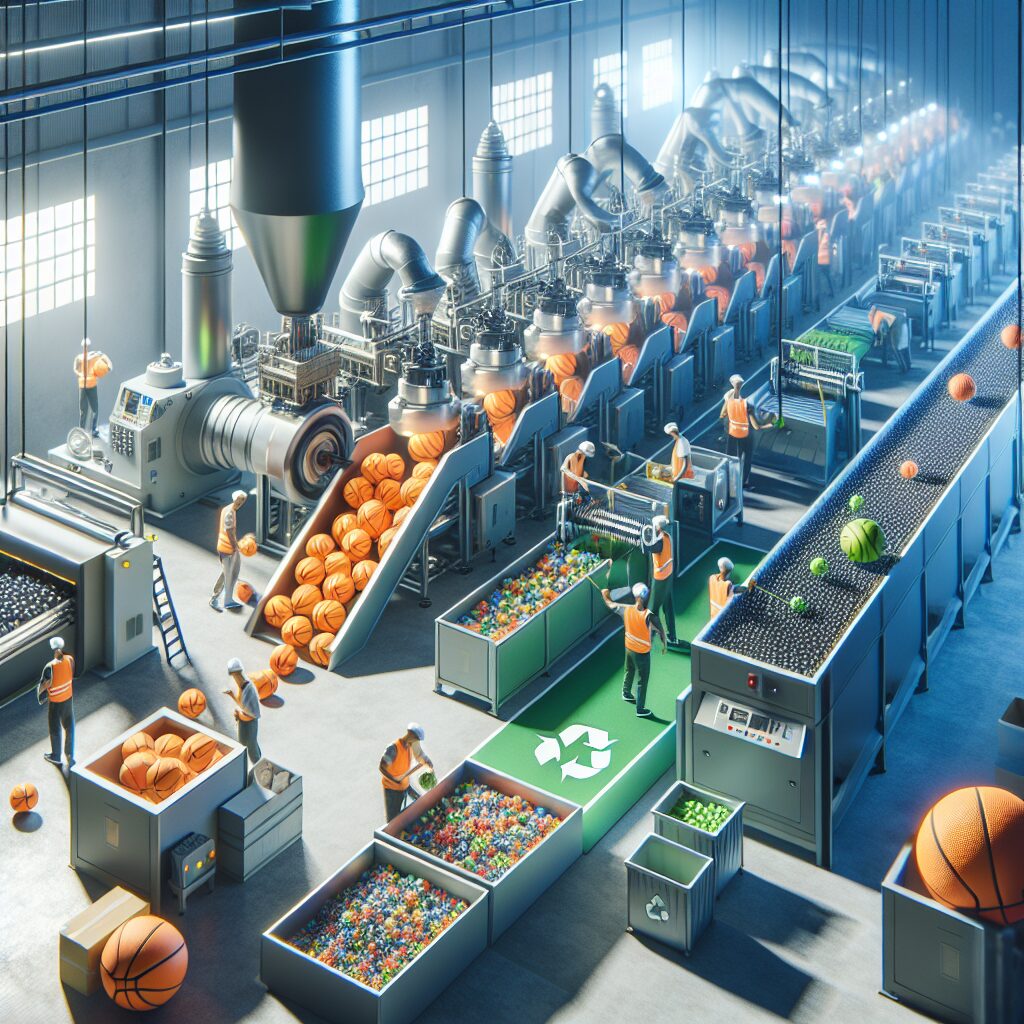

One unique factor that sets sustainable manufacturing in ball production apart is the emphasis on using recycled materials. By utilizing recycled materials for ball production, manufacturers are able to reduce the demand for new resources, minimizing the overall environmental footprint. Additionally, sustainable manufacturing practices also incorporate the use of renewable energy sources, such as solar or wind power, to power the manufacturing process. These initiatives have a significant impact on reducing carbon emissions and promoting a cleaner, greener future.

Moving forward, this article will delve into the key takeaways of sustainable manufacturing in ball production. We will explore the various techniques and strategies utilized in this process, including the adoption of circular economy principles, the role of technology in optimizing energy consumption, and the importance of collaborative efforts between manufacturers and suppliers. By understanding these key takeaways, readers will gain valuable insights into how sustainable manufacturing is leading the way in ball production and shaping the future of the industry.

Key Takeaways

1. Sustainable manufacturing is becoming increasingly important in the ball production industry due to growing consumer demand for eco-friendly products and the need to reduce environmental impact.

2. Companies in the ball production industry are implementing various strategies to achieve sustainability goals, such as using recycled materials, reducing energy consumption, and optimizing manufacturing processes.

3. Collaborative efforts between ball manufacturers, suppliers, and consumers are crucial for the success of sustainable manufacturing initiatives, as they require a collective commitment to environmentally friendly practices throughout the supply chain.

4. Sustainable manufacturing not only helps preserve the environment, but also brings economic benefits to companies, such as cost savings, increased customer loyalty, and improved brand reputation.

5. The adoption of sustainable manufacturing practices in the ball production industry serves as a model for other industries, highlighting the feasibility and benefits of transitioning towards more environmentally conscious and socially responsible manufacturing processes.

Can Sustainable Manufacturing Lead the Way in Ball Production?

The Importance of Sustainable Manufacturing in the Ball Production Industry

Sustainable manufacturing has become increasingly important in recent years, as industries across the globe are striving to reduce their environmental impact. In the ball production industry, sustainable manufacturing practices not only contribute to a greener environment but also help companies gain a competitive edge. By focusing on sustainability, ball manufacturers can lead the way towards a more environmentally friendly future.

Reducing Energy Consumption and Carbon Emissions

One of the key aspects of sustainable manufacturing in ball production is the reduction of energy consumption and carbon emissions. Ball manufacturers can achieve this by implementing energy-efficient equipment, utilizing renewable energy sources, and optimizing production processes. By minimizing their carbon footprint, these manufacturers can actively contribute to the fight against climate change.

Implementing Responsible Material Sourcing

In sustainable ball production, responsible material sourcing is crucial. Manufacturers must prioritize the use of recycled materials, such as recycled rubber or plastics, whenever possible. Additionally, they should explore alternative materials that have a lower environmental impact, without compromising the quality or performance of the balls. By sourcing materials responsibly, manufacturers can ensure the longevity of natural resources and reduce their reliance on virgin materials.

Adopting Waste Reduction and Recycling Measures

Another important aspect of sustainable manufacturing in ball production is waste reduction and recycling. Manufacturers can implement measures such as optimizing production processes to minimize waste generation, promoting the reuse of materials, and establishing efficient recycling systems. By adopting these practices, companies can significantly reduce their environmental footprint and contribute to a circular economy.

Investing in Research and Innovation

Sustainable manufacturing in ball production requires a commitment to research and innovation. Manufacturers should continually invest in the development of new technologies and processes that can further enhance sustainability. This could include advancements in material science, such as biodegradable or compostable materials, or the use of advanced manufacturing techniques that minimize waste and energy consumption. By embracing innovation, ball manufacturers can stay ahead of the competition while leading the way in sustainable production.

Guides for Sustainable Manufacturing in Ball Production:

- How to implement energy-efficient equipment in ball production?

- Tips for responsible material sourcing in sustainable ball manufacturing.

- Waste reduction and recycling strategies for ball manufacturers.

- How to promote research and innovation in sustainable ball production?

Frequently Asked Questions

1. What is sustainable manufacturing?

Sustainable manufacturing refers to the process of producing goods in an environmentally friendly and socially responsible manner, minimizing the negative impact on our planet and society.

2. How does sustainable manufacturing benefit the ball production industry?

Sustainable manufacturing practices in the ball production industry help reduce waste, energy consumption, and carbon emissions. It promotes the use of eco-friendly materials, efficient production systems, and safer working conditions, leading to a more sustainable and socially responsible industry.

3. What are some key sustainable manufacturing techniques used in ball production?

Some key sustainable manufacturing techniques used in ball production include recycling and reusing materials, incorporating renewable energy sources, optimizing production processes to reduce energy and water consumption, and implementing ethical labor practices.

4. How does sustainable manufacturing affect the quality of balls produced?

Sustainable manufacturing does not compromise the quality of balls produced. In fact, it often enhances the quality by encouraging innovation, using higher quality materials, and implementing more rigorous quality control measures to ensure the durability and performance of the balls.

5. Are sustainable balls more expensive than traditional balls?

Initially, sustainable balls may have a slightly higher price due to the investments required for sustainable manufacturing practices. However, in the long run, as sustainable practices become more widespread, the costs are expected to decrease, making sustainable balls more affordable.

6. Are sustainable balls as durable as traditional balls?

Yes, sustainable balls can be as durable as traditional balls, if not more. Sustainable manufacturing practices often emphasize the use of high-quality materials and improved manufacturing processes, resulting in balls that are built to last and withstand rigorous use.

7. How can consumers contribute to promoting sustainable manufacturing in the ball production industry?

Consumers can contribute to promoting sustainable manufacturing by choosing to purchase balls from brands that prioritize sustainability, supporting eco-friendly initiatives, and spreading awareness about the importance of sustainable practices in the industry.

8. What certifications or standards should I look for when purchasing sustainable balls?

When purchasing sustainable balls, look for certifications such as ISO 14001 (Environmental Management System), Oeko-Tex Standard 100 (safe and environmentally friendly production), and Bluesign (sustainable textile production). These certifications ensure that the balls were produced using environmentally friendly and socially responsible practices.

9. Can sustainable manufacturing practices be applied to other sports equipment?

Yes, sustainable manufacturing practices can be applied to various sports equipment. The principles of reducing waste, conserving resources, and promoting ethical production can be implemented in the manufacturing of equipment such as rackets, gloves, shoes, and protective gear.

10. How can sustainable manufacturing in the ball production industry have a broader positive impact?

Sustainable manufacturing in the ball production industry can have a broader positive impact by inspiring other industries to adopt similar practices, raising awareness about environmental and social responsibility, and contributing to a more sustainable and conscious society as a whole.

Final Thoughts on Sustainable Manufacturing: Leading the Way in Ball Production

In conclusion, sustainable manufacturing in the ball production industry is not only crucial for the longevity of our planet but also for the betterment of the industry itself. By adopting sustainable practices, such as reducing waste, conserving resources, and prioritizing social responsibility, the industry can lead the way towards a greener, more ethical future.

It is up to manufacturers, consumers, and industry stakeholders to recognize the importance of sustainable manufacturing and actively support the transition towards a more sustainable and socially responsible ball production industry. Together, we can make a significant difference and create a positive impact on both the environment and society as a whole.