Sustainable fabrication is a practice that involves the creation, development, and production of products using methods that minimize environmental impact. From clothing to furniture to home decor, sustainable fabrication is revolutionizing industries and paving the way for greener alternatives. One unique feature of sustainable fabrication is the use of eco-friendly materials, such as organic and recycled fibers, which are sourced and processed in a way that reduces harm to the environment. Additionally, sustainable fabrication focuses on reducing waste and energy consumption throughout the entire production process, aiming for an overall lower carbon footprint.

Now that we have explored the definition and unique features of sustainable fabrication, let’s delve into the specific impacts it has across various industries. From an environmental standpoint, sustainable fabrication plays a crucial role in reducing pollution, preserving natural resources, and mitigating climate change. By utilizing eco-friendly materials and adopting energy-efficient practices, companies can significantly reduce their carbon emissions. Furthermore, sustainable fabrication promotes ethical practices by ensuring fair wages and safe working conditions for workers involved in the manufacturing process. This not only benefits individuals but also fosters a positive social impact within local communities.

Moving forward, we will highlight the key takeaways from this article, discussing the ways in which sustainable fabrication is transforming industries and contributing to a greener future. We will explore the benefits it brings to consumers, businesses, and the planet as a whole. Additionally, we will discuss the challenges and potential solutions that arise when implementing sustainable fabrication practices. Stay tuned as we dive deeper into this fascinating and important topic.

Key Takeaways

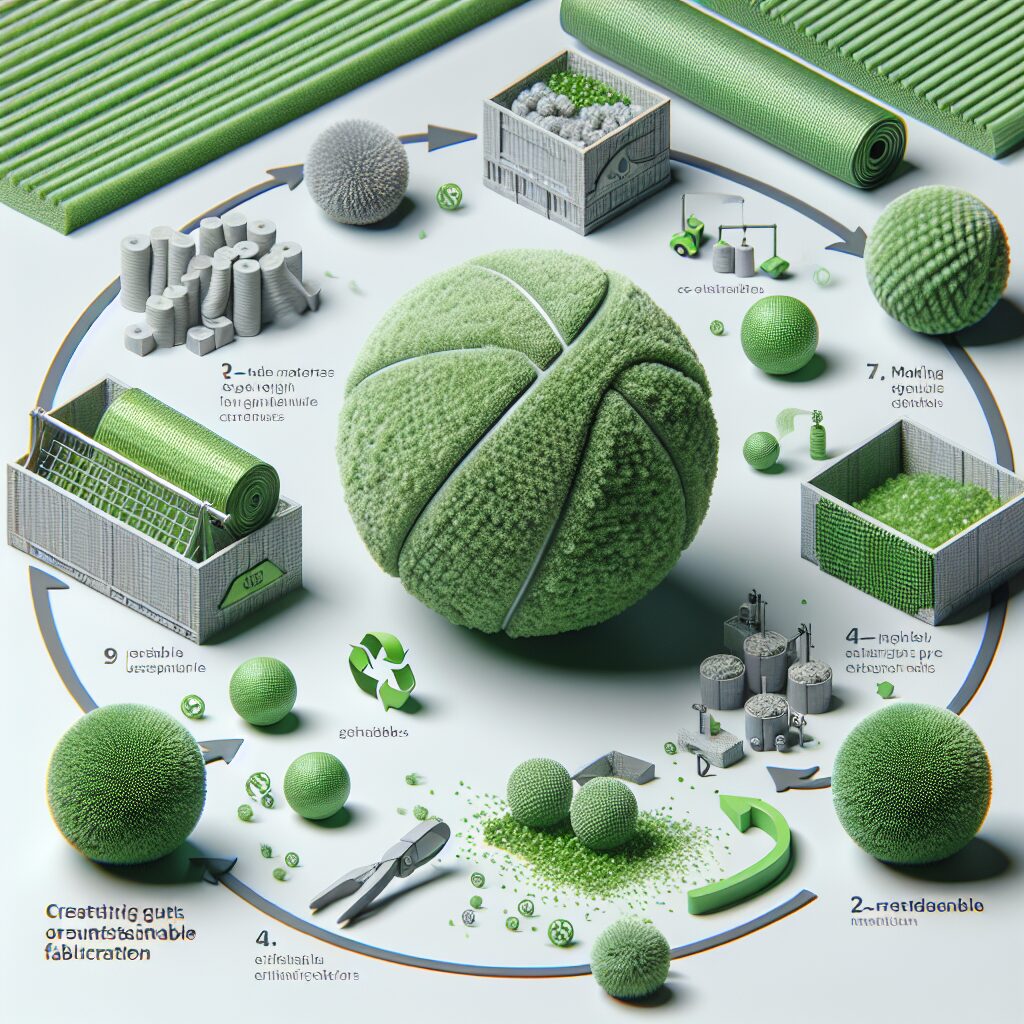

1. The article discusses the importance of sustainable fabrication in the production of balls, emphasizing the need for environmentally friendly materials and manufacturing processes. The impact of the sports industry on the environment is highlighted, along with the potential for sustainable solutions.

2. A wide range of eco-friendly materials can be used for ball production, including recycled rubber, organic cotton, and biodegradable plastics. These materials not only reduce waste and pollution but also promote a circular economy by utilizing recycled or biobased resources.

3. Sustainable fabrication involves implementing innovative manufacturing processes, such as using water-based inks for printing and reducing energy consumption during production. These practices help minimize the carbon footprint associated with ball manufacturing and contribute to a greener supply chain.

4. Collaborations between sportswear brands, research institutions, and sustainability organizations are vital in fostering the development and adoption of sustainable fabrication techniques. By working together, these entities can share knowledge, resources, and best practices to drive innovation in the industry.

5. Consumer demand for sustainable products and a growing awareness of environmental issues are driving the adoption of sustainable fabrication practices in the sports industry. As more consumers prioritize sustainability, brands are motivated to invest in greener alternatives, ensuring a positive and lasting impact on the environment.

1. Can Sustainable Fabrication Lead to Greener Balls?

Sustainable Materials for Greener Balls

When it comes to fabrication, the choice of materials plays a crucial role in determining the environmental impact. Sustainable fabrication processes aim to reduce the carbon footprint and promote eco-friendly practices. In the case of manufacturing balls, opting for materials such as recycled rubber or organic cotton can significantly contribute to greener production. These materials not only minimize waste but also decrease the reliance on non-renewable resources, making them a viable choice for sustainable fabrication.

Energy-Efficient Manufacturing Techniques

In addition to sustainable materials, implementing energy-efficient manufacturing techniques is essential for greener ball fabrication. Modern technologies like solar power or wind turbines can power factories, reducing the dependence on fossil fuels. Furthermore, optimizing production processes to minimize energy consumption and adopting renewable energy sources can significantly contribute to a greener fabrication process.

The Role of Recycling and Upcycling

To achieve sustainable fabrication of balls, recycling and upcycling must be at the core of the manufacturing process. By implementing effective recycling programs, manufacturers can repurpose materials like rubber, reducing the need for virgin resources. Additionally, upcycling methods can transform old or discarded materials into innovative and eco-friendly ball designs, further promoting sustainable fabrication practices.

Sustainable Supply Chains and Fair Trade

Sustainable fabrication goes beyond the factory walls and extends to the entire supply chain. Ensuring fair trade practices and working towards sustainable sourcing of materials is vital. By collaborating with suppliers who prioritize environmental and social responsibility, manufacturers can contribute to greener ball fabrication. This includes considering factors such as ethical labor practices and reducing the overall ecological impact throughout the entire production process.

Environmental Certifications and Standards

Obtaining relevant environmental certifications and adhering to strict standards is crucial for sustainable fabrication of balls. Certifications such as the Global Organic Textile Standard (GOTS) or the Forest Stewardship Council (FSC) provide reassurance that the production process aligns with sustainable practices. By complying with these certifications and standards, manufacturers can demonstrate their commitment to greener fabrication and build trust with environmentally conscious consumers.

Tips for Sustainable Fabrication: Paving the Way for Greener Balls

1. Incorporate recycled rubber or organic cotton as primary materials in ball fabrication.

2. Install solar panels or wind turbines to power manufacturing facilities.

3. Optimize production processes to minimize energy consumption.

4. Implement effective recycling and upcycling programs to reduce waste.

5. Collaborate with suppliers who prioritize fair trade and sustainable sourcing.

6. Obtain relevant environmental certifications to showcase commitment to sustainability.

7. Educate consumers about the environmental benefits of choosing greener balls.

And there you have it! The comprehensive guide to sustainable fabrication and greener balls. By implementing these practices and considering the environmental impact at every stage, we can pave the way for a more sustainable future in the world of ball manufacturing.

FAQ

What is sustainable fabrication?

Sustainable fabrication refers to the use of environmentally friendly manufacturing processes and materials that minimize negative impacts on the planet. It aims to create products in a way that promotes ecological balance, conservation of resources, and the well-being of the community.

Why is sustainable fabrication important?

Sustainable fabrication is important because it addresses the growing concerns about environmental degradation and climate change caused by traditional manufacturing practices. By using eco-friendly materials and processes, sustainable fabrication helps reduce pollution, waste, and energy consumption, ultimately leading to a greener and healthier planet.

How does sustainable fabrication benefit the textile industry?

Sustainable fabrication brings numerous benefits to the textile industry. It allows for the production of fabrics that have a lower carbon footprint, reducing the industry’s impact on climate change. Additionally, sustainable fabrication promotes the use of renewable resources and encourages the development of innovative and eco-friendly techniques, ultimately fostering a more sustainable and responsible textile sector.

What are some examples of sustainable fabrication techniques?

There are several examples of sustainable fabrication techniques, including the use of recycled or organic materials, employing energy-efficient production methods, implementing water-saving processes, and reducing waste through recycling and upcycling. Additionally, sustainable fabrication often involves the adoption of eco-certifications and transparent supply chains to ensure ethical sourcing and manufacturing.

Do sustainable fabrics compromise on quality and performance?

No, sustainable fabrics do not necessarily compromise on quality and performance. In fact, advancements in fabric technology have enabled the production of sustainable fabrics that are equal or superior in quality to their traditional counterparts. Sustainable fabrics can offer excellent durability, breathability, moisture-wicking properties, and even advanced functionalities such as UV protection or antibacterial properties, without compromising on sustainability.

Are sustainable fabrics more expensive?

Sustainable fabrics can sometimes be slightly more expensive than conventional fabrics due to the higher costs associated with the use of eco-friendly materials and sustainable manufacturing processes. However, as the demand for sustainable fabrics grows and production scales up, prices are becoming more competitive, making sustainable options more accessible and affordable for consumers.

What role do consumers play in promoting sustainable fabrication?

Consumers have a crucial role to play in promoting sustainable fabrication. By choosing products made from sustainable fabrics and supporting brands that prioritize eco-friendly manufacturing, consumers create a demand for sustainable options. This, in turn, incentivizes the industry to invest in and further develop sustainable fabrication techniques. By making informed choices and spreading awareness, consumers become powerful catalysts for positive change.

Can sustainable fabrication be applied to other industries beyond textiles?

Yes, sustainable fabrication principles can be applied to various industries beyond textiles. From construction and automotive to electronics and packaging, sustainable fabrication techniques can help reduce the environmental impact of diverse sectors. By adopting sustainable practices, such as using recycled materials, optimizing energy use, and minimizing waste, industries can work towards a greener future.

How can organizations embrace sustainable fabrication?

Organizations can embrace sustainable fabrication by evaluating their processes and supply chains to identify areas where sustainability improvements can be made. This may involve sourcing eco-friendly materials, implementing energy-efficient machinery, reducing emissions, and adopting circular economy practices. Collaborating with sustainable suppliers and obtaining relevant certifications can also help organizations demonstrate their commitment to sustainable fabrication.

What are the long-term benefits of sustainable fabrication?

The long-term benefits of sustainable fabrication are manifold. Not only does it contribute to a healthier planet by reducing greenhouse gas emissions and preserving natural resources, but it also fosters innovation and drives economic growth. Sustainable fabrication can enhance brand reputation, attract environmentally-conscious consumers, and ensure the long-term viability of industries in the face of increasing environmental regulations.

Final Thoughts

Sustainable fabrication is a vital step towards creating a greener and more sustainable future. By adopting eco-friendly materials and manufacturing processes, we can minimize the environmental impact of our products and contribute to the well-being of the planet. However, the responsibility does not solely lie with manufacturers and organizations. As consumers, we must actively support sustainable fabrication by making conscious choices and demanding transparency. Together, we can pave the way for a more sustainable textile industry and ultimately achieve a greener world.

In conclusion, sustainable fabrication offers a multitude of benefits, ranging from minimizing pollution and waste to promoting resource conservation and ethical practices. It is through the collective efforts of manufacturers, consumers, and organizations that the transformation towards greener balls becomes possible. By embracing sustainable fabrication, we can ensure a healthier planet for generations to come while still enjoying high-quality and innovative products. Let us embrace this journey towards sustainability and work together to pave the way for a greener future.