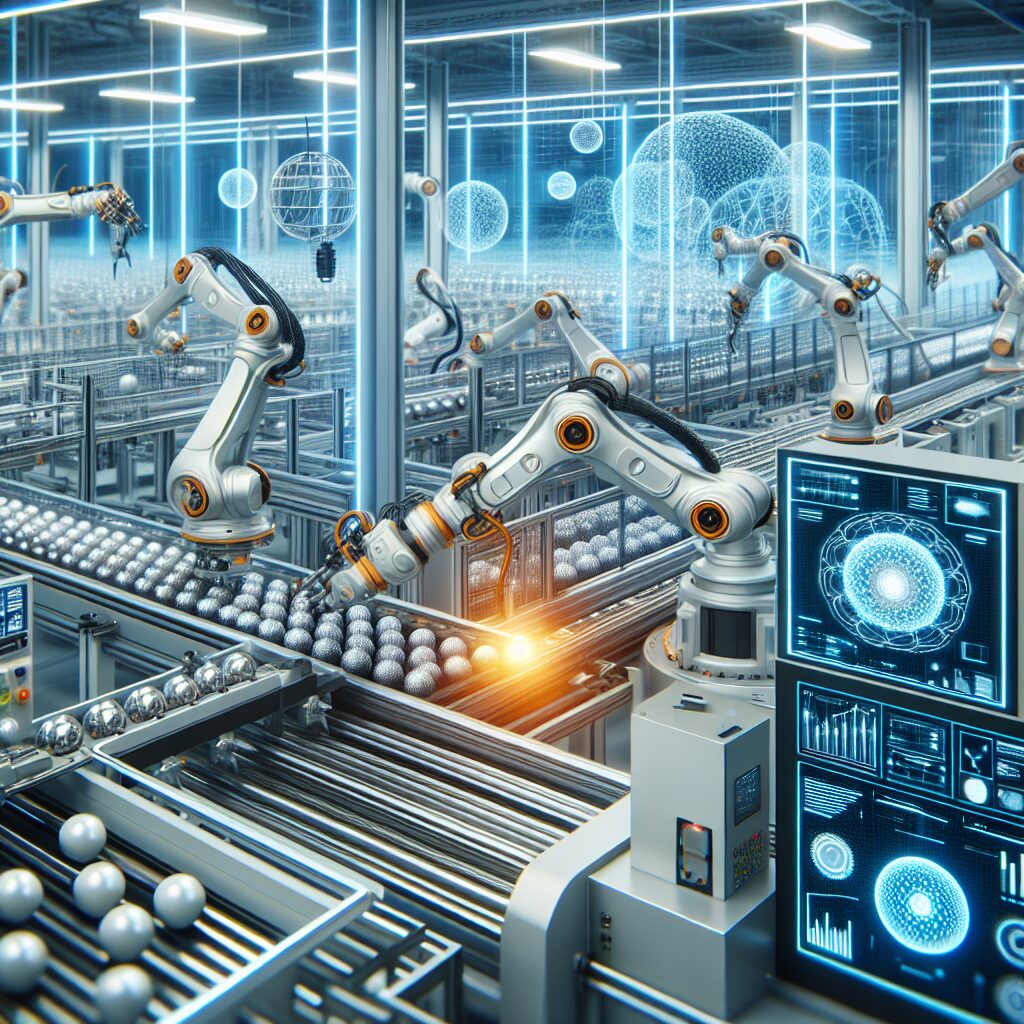

Smart manufacturing refers to the use of advanced technologies and automated systems in the production processes to improve productivity, efficiency, and quality. In the context of ball production, smart manufacturing is revolutionizing the way balls are manufactured, making it faster, more cost-effective, and sustainable. One unique insight related to this topic is the utilization of Internet of Things (IoT) devices and sensors in the manufacturing process, which enables real-time data collection and analysis. This data-driven approach allows manufacturers to monitor and optimize every step of ball production, from material selection to molding and finishing.

In addition to IoT technology, smart manufacturing in ball production also heavily relies on artificial intelligence (AI) and machine learning algorithms. These technologies enable machines to learn and adapt to different manufacturing conditions, thereby improving the accuracy and consistency of ball production. For instance, AI-powered quality control systems can identify defects or irregularities in the manufacturing process, allowing manufacturers to address them immediately and ensure high-quality balls. Furthermore, smart manufacturing facilitates automation, reducing the need for manual labor and streamlining the production process.

Moving forward, this article will discuss the key takeaways of smart manufacturing in ball production. We will explore how IoT devices and sensors revolutionize the manufacturing process, the benefits of AI and machine learning in improving quality control, and the impact of automation on efficiency and productivity. By delving into these aspects, we aim to provide insights into the future of ball production and how smart manufacturing is shaping the industry. So, let’s dive into the innovative world of smart manufacturing in ball production and discover the endless possibilities it offers.

Key Takeaways

1. Smart manufacturing is revolutionizing the ball production industry by integrating advanced technologies such as artificial intelligence, robotics, and the Internet of Things (IoT) into the manufacturing process.

2. The implementation of smart manufacturing in ball production leads to increased efficiency and improved product quality due to enhanced automation, real-time data monitoring, and predictive maintenance capabilities.

3. By leveraging the power of data analytics and machine learning, smart manufacturing enables manufacturers to optimize production workflows, minimize downtime, and make data-driven decisions to streamline operations.

4. The adoption of smart manufacturing in ball production opens up new opportunities for customization and personalization, allowing customers to specify their desired ball characteristics and have them manufactured on-demand with greater precision and consistency.

5. As smart manufacturing continues to evolve, it is expected to significantly reduce production costs, improve sustainability through resource optimization, and pave the way for innovative materials and designs in ball production.

What is the Future of Ball Production with Smart Manufacturing?

An Overview of Smart Manufacturing

Smart manufacturing is revolutionizing the production process across various industries, and ball production is no exception. With the integration of advanced technologies and automation, manufacturers are able to optimize efficiency, accuracy, and productivity in ball production.

The Role of Artificial Intelligence (AI) in Ball Production

One of the key components of smart manufacturing in ball production is the utilization of artificial intelligence (AI). AI enables machines and systems to learn, adapt, and make intelligent decisions, leading to improved quality control, reduced defects, and precision in ball production.

The Implementation of Internet of Things (IoT) in Ball Production

In the future of ball production, IoT plays a crucial role. IoT refers to the interconnectedness of devices and systems through the internet, enabling data exchange and real-time monitoring. By incorporating IoT into ball production, manufacturers can monitor various aspects such as temperature, pressure, and vibration, optimizing production parameters and ensuring consistent quality.

Benefits of Smart Manufacturing in Ball Production

The adoption of smart manufacturing in ball production offers numerous benefits. Firstly, it enables predictive maintenance, where machines and equipment can be monitored and maintained before breakdowns occur, reducing downtime and increasing overall productivity. Secondly, it enhances product quality through real-time data analysis and process optimization. Thirdly, it allows for customization and flexibility in production, catering to specific customer requirements.

Challenges in Implementing Smart Manufacturing for Ball Production

While smart manufacturing brings immense potential for ball production, it also presents challenges. The integration of advanced technologies requires significant investments and a well-planned implementation strategy. Additionally, acquiring the necessary expertise and upskilling the workforce to operate and maintain smart manufacturing systems can be a challenge for manufacturers.

The Future of Ball Production with Smart Manufacturing

The future of ball production lies in the seamless integration of smart manufacturing technologies. As technology continuously evolves, we can expect even greater automation, enhanced data analytics, and more efficient processes in the production of balls. With advancements such as machine learning and robotics, ball manufacturers will achieve higher precision, faster production, and increased customization capabilities.

Guides and Tips for Implementing Smart Manufacturing in Ball Production

1. Begin by conducting a thorough assessment of your current production process and identify areas for improvement through smart manufacturing technologies.

2. Invest in advanced machinery and equipment that are compatible with smart manufacturing systems, ensuring seamless integration and optimal performance.

3. Collaborate with technology providers and experts in the field to design and implement a tailored smart manufacturing solution for your specific ball production needs.

4. Train and upskill your workforce to operate and maintain the smart manufacturing systems effectively, maximizing their potential and ensuring smooth operations.

5. Continuously monitor and analyze the data collected from smart manufacturing systems to identify patterns and areas for further optimization, allowing for continuous improvement in ball production.

Frequently Asked Questions

What is smart manufacturing?

Smart manufacturing is the use of advanced technologies and data analytics to optimize and automate industrial processes, improve efficiency, and enhance product quality in manufacturing. It involves the integration of artificial intelligence, Internet of Things (IoT), automation, and data analytics to create intelligent and interconnected systems.

How does smart manufacturing apply to ball production?

In ball production, smart manufacturing can revolutionize the production process by using sensors and data analytics to monitor and control various aspects of the manufacturing process. This can include optimizing raw material selection, automating quality control checks, and streamlining production workflows. Smart manufacturing can also enable real-time data analysis to identify and resolve any production issues quickly, resulting in improved productivity and higher-quality balls.

What are the benefits of implementing smart manufacturing in ball production?

Implementing smart manufacturing in ball production offers several benefits. It can enhance the overall efficiency of the manufacturing process, reduce production costs, minimize waste, and improve product quality. Additionally, smart manufacturing enables predictive maintenance, allowing manufacturers to proactively address equipment issues before they lead to costly downtimes. It also enables manufacturers to gather valuable insights from the production data, empowering them to make data-driven decisions and continuously optimize their processes.

Is smart manufacturing only applicable to large production facilities?

No, smart manufacturing can be implemented in production facilities of all sizes. While large facilities may have more resources to invest in advanced technologies and systems, smaller facilities can also benefit from implementing smart manufacturing solutions on a smaller scale. The key is to identify the specific areas where automation and data analysis can bring significant improvements and start implementing smart manufacturing gradually.

What challenges may arise when adopting smart manufacturing in ball production?

Implementing smart manufacturing in ball production may face several challenges. Some common challenges include initial investment costs, integration of different systems, employee training, and ensuring data security and privacy. To overcome these challenges, it is essential for manufacturers to carefully plan and strategize the implementation, seek support from experts, and prioritize continuous improvement and learning.

Will smart manufacturing lead to job losses in ball production?

While smart manufacturing may automate certain tasks in ball production, it does not necessarily lead to widespread job losses. Instead, it can result in a shift in job roles and responsibilities. With automation handling repetitive and mundane tasks, human workers can focus on more complex and critical functions, such as process optimization, data analysis, and maintenance. Smart manufacturing can ultimately create new job opportunities that require specific skills in operating and maintaining advanced manufacturing systems.

How does smart manufacturing impact product quality in ball production?

Smart manufacturing significantly enhances product quality in ball production. By leveraging real-time data analytics and automated quality control measures, manufacturers can continuously monitor and detect any deviations in the production process. This enables timely corrective actions, ensuring consistent and high-quality ball production. Smart manufacturing also facilitates traceability and transparency by tracking key information throughout the production process, further enhancing product quality control and customer confidence.

What technologies are essential for implementing smart manufacturing in ball production?

Several technologies are essential for implementing smart manufacturing in ball production. These include IoT sensors, robotics, artificial intelligence, cloud computing, data analytics software, and connectivity infrastructure. These technologies work together to enable real-time data collection, analysis, and integration across various stages of the production process, driving efficiency, automation, and continuous improvement.

Can smart manufacturing be retrofitted into existing ball production facilities?

Yes, smart manufacturing can be retrofitted into existing ball production facilities. While it may require some adjustments and upgrades to the existing infrastructure, implementing smart manufacturing doesn’t necessarily require building new facilities from scratch. By strategically integrating smart technologies into the existing production systems, manufacturers can gradually transition to smart manufacturing and benefit from its advantages without disrupting their operations.

What is the future outlook for smart manufacturing in ball production?

The future of smart manufacturing in ball production looks promising. As technology continues to advance, we can expect further integration of AI, machine learning, and automation into the manufacturing processes. This will lead to increased efficiency, improved customization capabilities, and faster time-to-market for ball manufacturers. Additionally, the ongoing advancements in connectivity and data analytics will enable more sophisticated predictive maintenance and real-time optimization, supporting continuous improvement in product quality and overall production performance.

Final Thoughts

The adoption of smart manufacturing in the ball production industry holds immense potential for transforming the way balls are manufactured. By harnessing the power of advanced technologies and data-driven insights, manufacturers can achieve higher levels of efficiency, sustainability, and product quality. However, it is crucial for manufacturers to approach the implementation with careful planning, ensuring appropriate investments, and providing necessary training to employees to fully capitalize on the benefits of smart manufacturing.

As smart manufacturing continues to evolve, innovation will unlock new opportunities for ball manufacturers to stay competitive in a rapidly changing market. Embracing the future of ball production through smart manufacturing is not only a necessity for survival but also a pathway to unlock new levels of operational excellence, customer satisfaction, and business growth.