Rubber Recycling: Sustainability in Ball Manufacturing

Did you know that rubber recycling plays a key role in sustainable ball manufacturing? Rubber, a versatile material known for its elasticity and resilience, has become a vital component in the production of various sports balls. However, the environmental impact of rubber production and waste disposal is a growing concern. This is where rubber recycling comes into the picture, offering a solution that not only reduces the negative impact on the environment but also enhances the sustainability of ball manufacturing.

Rubber recycling brings about several specific impacts and unique features that benefit the manufacturing process. Firstly, it helps reduce the reliance on virgin rubber, which involves harvesting and processing raw rubber from trees. By using recycled rubber, ball manufacturers can minimize the consumption of natural resources and preserve valuable ecosystems. Additionally, rubber recycling reduces the amount of rubber waste that would otherwise end up in landfills, contributing to pollution and resource depletion. By transforming discarded rubber materials into new balls, the recycling process promotes a circular economy, ensuring that resources are kept in use for as long as possible.

Moving on, let’s delve into the key takeaways of rubber recycling in ball manufacturing. We will explore the technological advancements and innovative practices that enable the recycling process to be efficient and cost-effective. Furthermore, we will discuss the various benefits of utilizing recycled rubber in ball production, such as improved durability and performance. Stay tuned to discover how rubber recycling revolutionizes the sustainability of ball manufacturing, paving the way for a greener and more eco-friendly future.

Key Takeaways

1. Rubber recycling plays a crucial role in promoting sustainability within ball manufacturing, reducing waste and preserving natural resources.

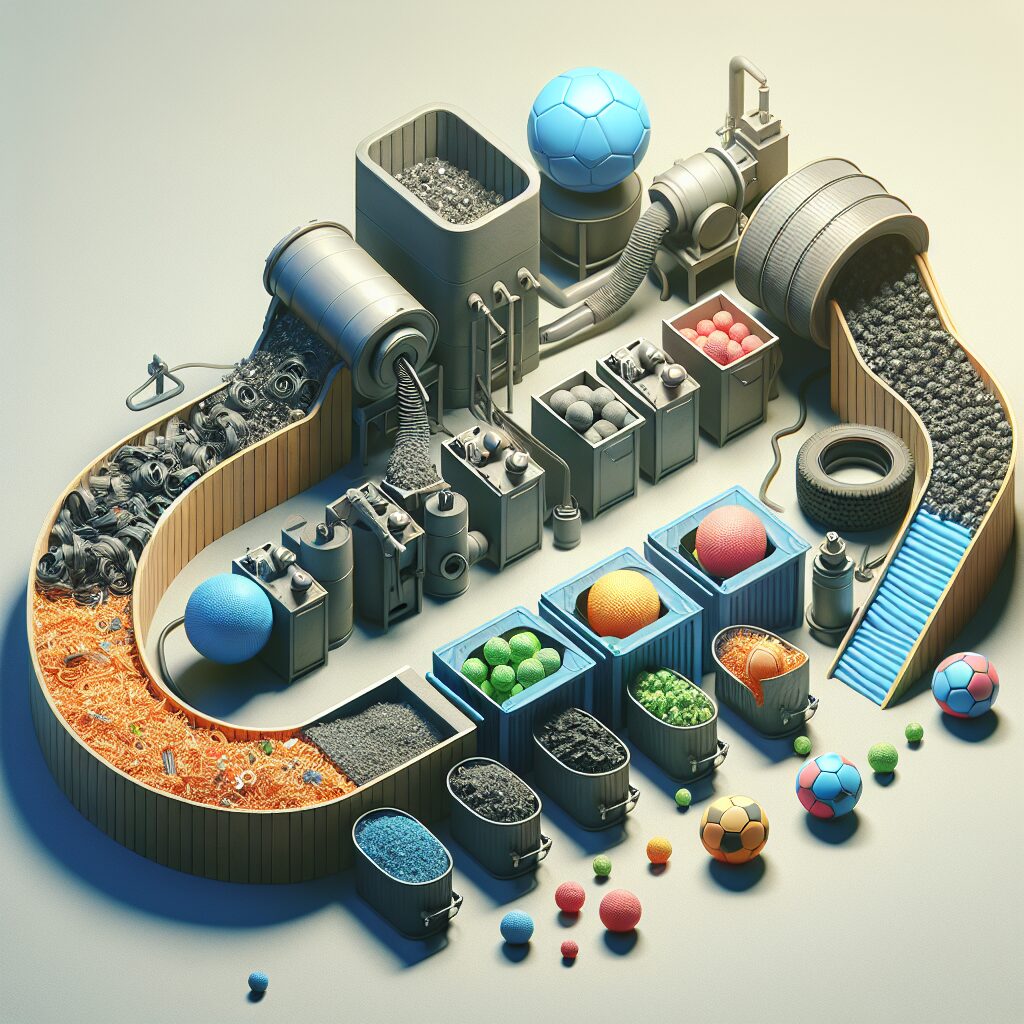

2. The process of rubber recycling involves collecting used rubber material, shredding it, and then converting it into various usable forms, such as granulated rubber or rubber powder.

3. Recycled rubber is a versatile and cost-effective alternative to virgin rubber, offering equivalent performance characteristics while also reducing the environmental impact of production.

4. By incorporating recycled rubber into ball manufacturing, companies are able to contribute to a circular economy and reduce their carbon footprint, while maintaining product quality and performance.

5. In addition to environmental benefits, the use of recycled rubber in ball manufacturing also provides economic advantages, including reduced raw material costs and potential government incentives for sustainable practices.

What is the Importance of Rubber Recycling in Ball Manufacturing?

The Environmental Impact of Rubber Waste

Rubber waste generated from various industries poses a significant threat to the environment. Discarded rubber products such as tires, shoe soles, and industrial rubber scraps often end up in landfills, taking up valuable space and causing pollution. The burning of rubber waste releases harmful chemicals and contributes to air pollution. Rubber recycling plays a crucial role in mitigating these environmental issues and promoting sustainability in ball manufacturing.

Benefits of Rubber Recycling

1. Conservation of Natural Resources: By recycling rubber, we can reduce the demand for virgin rubber, which is derived from rubber trees. This conserves natural resources and protects delicate ecosystems.

2. Energy and Cost Savings: The process of recycling rubber requires less energy and resources compared to producing new rubber from raw materials. Recycling also eliminates the need for costly waste disposal.

3. Reduction of Landfill Waste: Rubber waste takes up significant space in landfills, leading to limited capacity for other valuable materials. Recycling rubber reduces the volume of waste going to landfills, extending their lifespan and minimizing environmental impact.

The Role of Rubber Recycling in Ball Manufacturing

1. Production of Recycled Rubber Granules: Rubber recycling facilities turn rubber waste into granules that can be used in various applications, including ball manufacturing. These granules can exhibit properties similar to virgin rubber, making them suitable for use in producing high-quality balls.

2. Enhancing Ball Performance: Recycled rubber granules can positively impact the performance of balls used in various sports. The incorporation of recycled rubber can improve bounce, grip, and durability, providing a sustainable alternative without compromising functionality.

3. Eco-friendly Sports Equipment: Utilizing recycled rubber in ball manufacturing promotes sustainability throughout the sports industry. Athletes and sports enthusiasts can enjoy their favorite activities while knowing that their equipment is environmentally responsible.

Challenges and Solutions

While rubber recycling for ball manufacturing brings numerous benefits, there are challenges that need to be addressed:

Contamination: Rubber waste may contain contaminants that affect the quality of the recycled material. Proper sorting and processing procedures are crucial to minimize contamination and produce high-grade recycled rubber.

Infrastructure: Developing efficient rubber recycling infrastructure is vital to ensure the scalability and accessibility of the recycling process. Governments, industries, and communities should collaborate to establish comprehensive recycling systems.

Conclusion

By prioritizing rubber recycling in ball manufacturing, we can reduce environmental harm, conserve resources, and create sustainable sports equipment. Collaboration between industries, government bodies, and consumers is essential in promoting the adoption of recycled rubber materials and supporting a greener future for the sports industry.

How to Incorporate Rubber Recycling in Ball Manufacturing? (5 Guides)

- Identify local rubber recycling facilities and establish partnerships to ensure a reliable supply of recycled rubber materials.

- Conduct thorough testing and research on the performance characteristics of recycled rubber granules to determine their suitability for specific types of balls.

- Educate consumers about the benefits of using balls made from recycled rubber and the positive environmental impact of their choice.

- Collaborate with sports organizations, athletes, and influencers to raise awareness about the importance of sustainable ball manufacturing and encourage its adoption.

- Invest in research and development to continuously improve the quality and performance of balls made from recycled rubber, further driving sustainability in the industry.

Frequently Asked Questions

1. How does rubber recycling contribute to sustainability in ball manufacturing?

Rubber recycling plays a significant role in promoting sustainability in ball manufacturing. By reusing rubber waste, we reduce the demand for new raw materials, conserving natural resources and minimizing environmental impact. Additionally, recycling rubber helps to reduce landfill waste, as rubber takes a significant amount of time to decompose.

2. What types of balls are produced using recycled rubber?

A wide range of balls can be made using recycled rubber. Common examples include basketballs, soccer balls, volleyballs, golf balls, and dodgeballs. These balls undergo a rigorous manufacturing process that combines recycled rubber with other materials to ensure durability and performance.

3. Is recycled rubber as durable as newly produced rubber?

Yes, recycled rubber is just as durable as newly produced rubber. The recycling process involves breaking down the rubber into its original components and then reforming it into new products. This ensures that the mechanical properties and durability of the recycled rubber remain intact, making it suitable for ball manufacturing.

4. Are there any safety concerns associated with using recycled rubber in balls?

No, using recycled rubber in the production of balls does not pose any safety concerns. Recycled rubber undergoes thorough testing to ensure that it meets all safety standards and regulations. These tests evaluate factors such as bounce, impact resistance, and chemical composition to ensure the safety and performance of the final product.

5. How does rubber recycling benefit the environment?

Rubber recycling offers several environmental benefits. By diverting rubber waste from landfills, we reduce greenhouse gas emissions and prevent the release of harmful chemicals into the environment. Additionally, recycling rubber conserves energy and water resources that would otherwise be required for the production of new rubber.

6. Can recycled rubber balls be recycled again?

Yes, recycled rubber balls can be recycled again. After their lifespan, these balls can be collected and processed through rubber recycling facilities to be transformed into new rubber products. This circular approach further extends the environmental benefits of using recycled rubber in ball manufacturing.

7. Are there any cost savings associated with using recycled rubber in ball manufacturing?

Yes, using recycled rubber in ball manufacturing can result in cost savings. Compared to the production of new rubber, recycling rubber requires less energy and resources, therefore reducing production costs. Additionally, some governments offer incentives or grants to businesses that incorporate recycled materials in their manufacturing processes, further contributing to cost savings.

8. Can I contribute to rubber recycling as an individual?

Absolutely! As an individual, you can contribute to rubber recycling by ensuring proper disposal of rubber products, such as old balls, at designated recycling centers. Additionally, you can support eco-friendly brands that prioritize the use of recycled rubber in their ball manufacturing processes. Every small effort counts towards promoting sustainability.

9. Are there any limitations to using recycled rubber in ball manufacturing?

While the use of recycled rubber in ball manufacturing offers numerous benefits, there are some limitations to consider. Recycled rubber may not always be available in large quantities, depending on the availability of rubber waste for recycling. Additionally, certain specialized balls may require specific properties that may be challenging to achieve solely with recycled rubber.

10. What initiatives are in place to promote rubber recycling in ball manufacturing?

Several industry initiatives and organizations exist to promote rubber recycling in ball manufacturing. These initiatives focus on raising awareness, improving recycling technologies, and supporting research and development efforts to enhance the performance and sustainability of recycled rubber products. Collaboration between manufacturers, governments, and consumers plays a crucial role in driving these initiatives forward.

Final Thoughts on Rubber Recycling: Sustainability in Ball Manufacturing

Rubber recycling undoubtedly holds great potential for achieving sustainability in ball manufacturing. By embracing this practice, not only do we reduce our environmental footprint, but we also contribute to the conservation of natural resources. The integration of recycled rubber into the production of various ball types showcases the versatility and durability of this eco-friendly material.

As we move forward, it is essential for all stakeholders, including manufacturers, consumers, and governments, to actively support and promote rubber recycling initiatives. By doing so, we can create a more sustainable future where the recycling and reuse of rubber become standard practices, benefiting both the industry and the planet.