Reducing the Carbon Footprint: Eco-Conscious Ball Production

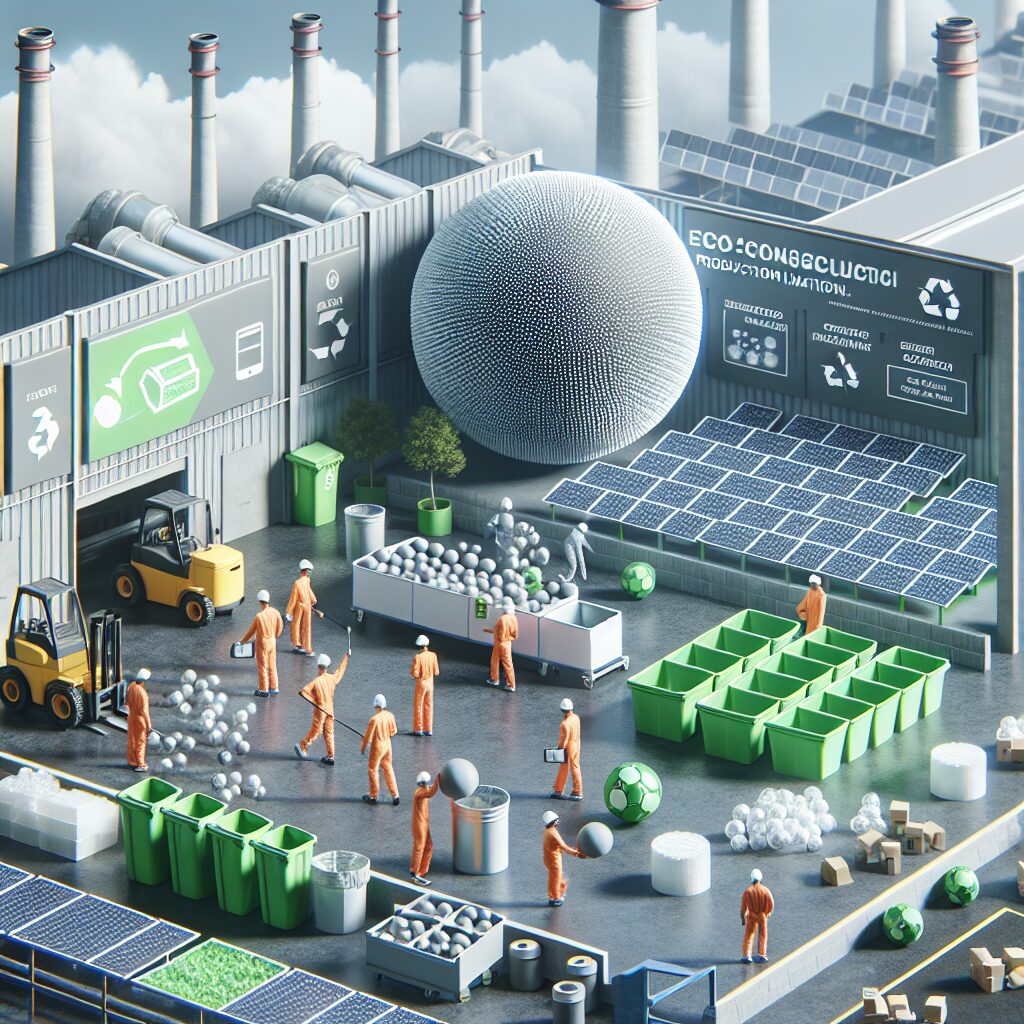

In an era where environmental consciousness is gaining prominence, the need to reduce our carbon footprint across various industries has become a pressing concern. This holds particularly true for the sports manufacturing sector, where the production of equipment can have a significant impact on the environment. Take, for instance, the production of sports balls, which not only require the extraction and processing of raw materials but also emit greenhouse gases during manufacturing. Recognizing the need for sustainable practices, many sports manufacturers are now shifting towards eco-conscious ball production methods to minimize their environmental impact.

One key aspect of eco-conscious ball production is the utilization of recycled materials. By reusing materials such as rubber and plastics recovered from discarded balls or other sources, manufacturers can significantly reduce their reliance on virgin materials. This not only conserves natural resources but also helps in minimizing waste and the energy required for extraction and processing. Additionally, the use of recycled materials often allows for a reduction in carbon emissions, as the manufacturing process for recycled materials tends to have a lower carbon footprint compared to the production of new materials. Moreover, these eco-conscious practices also contribute to a circular economy, where materials are reused or recycled rather than being wasted.

Moving forward, this article will delve into some key takeaways from the eco-conscious ball production trend. We will explore various sustainable manufacturing methods employed by sports manufacturers, including the use of renewable energy, biodegradable materials, and improved production techniques that minimize environmental impact. Join us as we uncover the innovative ways the sports industry is playing its part in reducing the carbon footprint and creating a more sustainable future. Stay tuned for actionable insights and impactful solutions that you can adopt in your own life or business ventures.

Key Takeaways

1. Material selection plays a crucial role in reducing the carbon footprint of ball production, with natural rubber and recycled materials being more eco-friendly alternatives than synthetic materials.

2. Adopting sustainable manufacturing practices, such as utilizing renewable energy sources and implementing efficient waste management strategies, is necessary to lower the environmental impact of ball production.

3. Implementing a circular economy approach by promoting ball recycling programs and designing products with recyclable components can contribute significantly to reducing the carbon footprint.

4. Collaboration among various stakeholders including manufacturers, suppliers, and consumers is essential to create a more environmentally conscious ball production industry.

5. Educating consumers about the environmental impacts of their purchasing decisions and the benefits of eco-friendly balls can lead to increased demand for sustainable products and help drive innovation in the industry.

How Can Eco-Conscious Ball Production Reduce the Carbon Footprint?

1. Sustainable Materials

One crucial aspect of reducing the carbon footprint in ball production is utilizing sustainable materials. Manufacturers can opt for eco-friendly alternatives such as recycled materials, organic fibers, or biodegradable components. By choosing these materials, the production process becomes less resource-intensive and lowers carbon emissions.

2. Energy-Efficient Manufacturing Processes

The manufacturing process plays a significant role in carbon footprint reduction. Implementing energy-efficient technologies and practices can make a considerable difference. By utilizing renewable energy sources like solar or wind power, manufacturers can minimize greenhouse gas emissions and decrease their overall environmental impact.

3. Waste Minimization and Recycling

Waste management is essential in eco-conscious ball production. Implementing effective recycling programs ensures that resources are reused, reducing the need for raw materials and minimizing waste sent to landfills. Additionally, proper waste disposal and recycling prevent pollution and preserve natural resources.

4. Reduced Packaging and Transportation

Reducing the carbon footprint also involves considering packaging and transportation aspects. By opting for minimal and eco-friendly packaging solutions, manufacturers can significantly reduce waste and energy consumption. Additionally, optimizing transportation routes and utilizing low-emission vehicles can help minimize the carbon footprint associated with distributing the eco-conscious balls.

5. Partnering with Sustainable Suppliers

Collaborating with eco-conscious suppliers is a crucial step in reducing the overall carbon footprint. By ensuring that suppliers share the same commitment to sustainability, manufacturers can source materials and resources that align with their eco-conscious production methods. This collaboration promotes a more sustainable supply chain and contributes to minimizing the carbon footprint of the entire production process.

6. Educating Consumers on Eco-Conscious Choices

Lastly, raising awareness and educating consumers about eco-conscious ball production can have a significant impact. Providing information about the production process and the environmental benefits of choosing eco-friendly balls can motivate consumers to make more sustainable choices. Encouraging conscious consumer behavior will foster demand for eco-conscious products and contribute to further reducing the carbon footprint.

Guides for Reducing the Carbon Footprint in Ball Production:

- How can you implement sustainable materials in ball production?

- What are some techniques for improving energy efficiency during manufacturing?

- How can you establish effective waste management and recycling systems?

- What strategies can be implemented to minimize packaging and transportation emissions?

- How can manufacturers ensure sustainable sourcing and collaboration with suppliers?

- What role does consumer education play in reducing the carbon footprint of ball production?

Frequently Asked Questions

1. What is eco-conscious ball production?

Eco-conscious ball production refers to the manufacturing process of sports balls with a focus on reducing the carbon footprint and environmental impact. It involves implementing sustainable practices like using recycled or organic materials, minimizing energy consumption, and reducing waste generation.

2. Why is reducing the carbon footprint important in ball production?

Reducing the carbon footprint in ball production is essential because the sports industry has a significant impact on the environment. By adopting eco-conscious practices, we can mitigate the release of greenhouse gases, conserve natural resources, and minimize pollution associated with the production and disposal of sports balls.

3. How are eco-conscious balls different from regular balls?

Eco-conscious balls are distinguishable from regular balls as they are designed to minimize environmental impact. They are often made from recycled or sustainable materials, use non-toxic dyes, and prioritize energy-efficient manufacturing processes. These balls aim to meet the same performance standards while reducing their carbon footprint.

4. Can eco-conscious balls maintain high durability and performance?

Yes, eco-conscious balls can maintain high durability and performance. Manufacturers are committed to producing eco-conscious balls that meet the industry’s standards for quality, strength, and performance. They undergo rigorous testing to ensure they can withstand the demands of professional and recreational sports without compromising on durability or playability.

5. How can individuals contribute to reducing the carbon footprint in ball production?

Individuals can contribute to reducing the carbon footprint in ball production by supporting brands that prioritize sustainability. Choosing eco-conscious balls made from recycled materials, encouraging proper ball maintenance for prolonged use, and recycling old balls instead of disposing of them can all make a positive impact on the environment.

6. Are eco-conscious balls more expensive than regular ones?

Eco-conscious balls may be slightly more expensive than regular ones due to the use of sustainable materials and eco-friendly manufacturing processes. However, with the growing demand for environmentally friendly products, the prices are becoming more competitive, and the long-term benefits of reducing the carbon footprint outweigh the minimal price difference.

7. Can eco-conscious ball production create job opportunities?

Absolutely! The shift towards eco-conscious ball production not only benefits the environment but also creates new job opportunities. Companies specializing in sustainable manufacturing require skilled workers to develop, produce, and market these eco-friendly balls. This industry can contribute to the growth of green jobs and boost the economy.

8. Are there any certifications or standards for eco-conscious ball production?

Yes, several certifications and standards exist for eco-conscious ball production. Some well-known certifications include those provided by Eco-Cert, Global Organic Textile Standard (GOTS), and Forest Stewardship Council (FSC). These certifications ensure that the manufacturing process adheres to strict environmental criteria and helps consumers identify genuinely eco-conscious products.

9. How can community sports clubs promote eco-conscious ball production?

Community sports clubs can promote eco-conscious ball production by educating their members about the benefits of sustainable products. They can encourage players to use eco-conscious balls during training sessions and competitions, organize awareness campaigns, and collaborate with eco-friendly ball manufacturers to offer discounts or sponsorship opportunities for clubs that prioritize sustainability.

10. What other initiatives can complement eco-conscious ball production?

Several initiatives can complement eco-conscious ball production and further reduce the environmental impact of the sports industry. These include investing in renewable energy sources to power ball manufacturing facilities, implementing efficient waste management systems, supporting reforestation projects, and promoting sustainable transportation options for ball distribution.

Final Thoughts: Reducing the Carbon Footprint in Eco-Conscious Ball Production

Embracing eco-conscious ball production is a crucial step towards a more sustainable sports industry. By prioritizing the reduction of carbon emissions, the use of recycled materials, and the adoption of environmentally friendly manufacturing practices, we can minimize the negative impact on our planet while continuing to enjoy the thrill of sports. It is essential for manufacturers, consumers, and sports organizations to collectively embrace these practices and make conscious choices that contribute to a greener future.

As individuals, we have the power to make a difference by supporting eco-conscious ball production, educating others about its benefits, and demanding sustainable options in our sporting activities. By making eco-conscious choices, we actively contribute to reducing the carbon footprint and ensure a healthier environment for generations to come. Let’s play our part in creating an eco-friendly sports culture by hitting the field with balls that score on sustainability.