Quality Assurance Measures: Raising the Bar for Balls

Quality assurance measures are an indispensable aspect of ensuring the overall performance and durability of products. When it comes to balls, be it for sports, industrial applications, or children’s play, the importance of implementing stringent quality assurance measures cannot be overstated. Did you know that the effectiveness of a ball is not solely determined by its design or materials used, but is heavily influenced by the quality assurance measures in place during its manufacturing process? This intriguing insight shines a light on the critical role of quality assurance in raising the bar for balls.

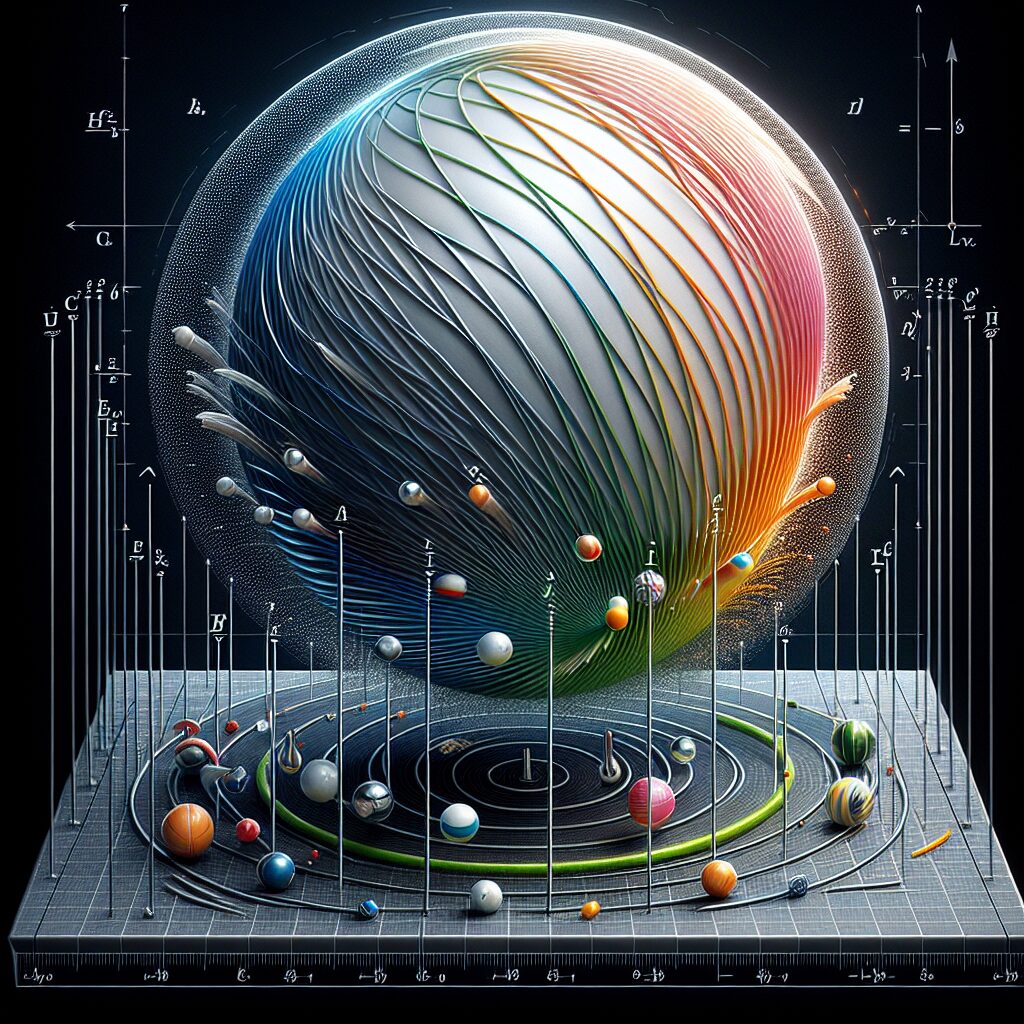

One of the key impacts of implementing robust quality assurance measures in ball manufacturing is the assurance of consistency and reliable performance. From ensuring optimal bounce in sports balls to maintaining durability in industrial spheres, quality assurance measures guarantee that each ball manufactured meets the predetermined standards. This not only enhances user experience but also minimizes the risk of faulty or subpar products reaching the market. Moreover, quality assurance measures help identify and rectify any potential manufacturing flaws or weaknesses, preventing product failures and promoting long-lasting performance.

In the subsequent sections of this article, we will delve deeper into the intricacies of quality assurance measures adopted in ball manufacturing. Exploring the various stages of the quality control process, we will discuss the key takeaways for manufacturers and consumers alike. By gaining an understanding of the critical factors contributing to ball quality enhancement, readers will be equipped with valuable insights to make informed decisions and appreciate the importance of quality assurance measures in ensuring the pinnacle of performance and durability. Stay tuned to discover the secrets behind the seamless bounce and unparalleled reliability of your favorite balls.

Key Takeaways

1. Quality assurance measures have become increasingly vital in the manufacturing of balls, as they not only ensure the durability and performance of the products but also contribute to customer satisfaction.

2. Consistency in materials, size, and weight is crucial for maintaining quality standards in ball production. By implementing strict guidelines and regular inspections, manufacturers can avoid variations and maintain uniformity across their product line.

3. Modern technology has significantly improved quality assurance measures for balls. Advanced equipment such as 3D scanners and computerized testing machines enable manufacturers to detect even the slightest defects or discrepancies, ensuring high-quality products reach the market.

4. Collaborations between ball manufacturers and research institutions have provided valuable insights for enhancing quality assurance practices. By conducting thorough research, analyzing data, and implementing innovative techniques, manufacturers can continuously improve the quality of their products.

5. Quality assurance measures extend beyond the production stage, as customer feedback and ongoing product testing help manufacturers identify areas for improvement and make necessary adjustments. This constant vigilance ensures that the quality of balls stays consistently high in response to evolving consumer needs and preferences.

What are the SEO-Optimized Quality Assurance Measures for Raising the Bar for Balls?

Understanding Quality Assurance Measures

Quality assurance measures are essential in any industry, especially when it comes to manufacturing products like balls. These measures ensure that the balls produced meet the highest quality standards and provide optimal performance to users. When it comes to raising the bar for balls, implementing effective quality assurance measures is crucial. Let’s delve into the various aspects of quality assurance and how it can elevate the ball production process.

Selecting Quality Materials for Ball Manufacturing

One of the fundamental aspects of quality assurance measures for balls is using superior materials during the manufacturing process. Choosing the right materials ensures durability, performance, and user satisfaction. Factors such as material strength, flexibility, and resistance to wear and tear play a vital role. Moreover, considering the specific requirements for different types of balls, such as soccer balls or tennis balls, is essential to meet the expectations of athletes and sports enthusiasts.

Rigorous Testing Procedures

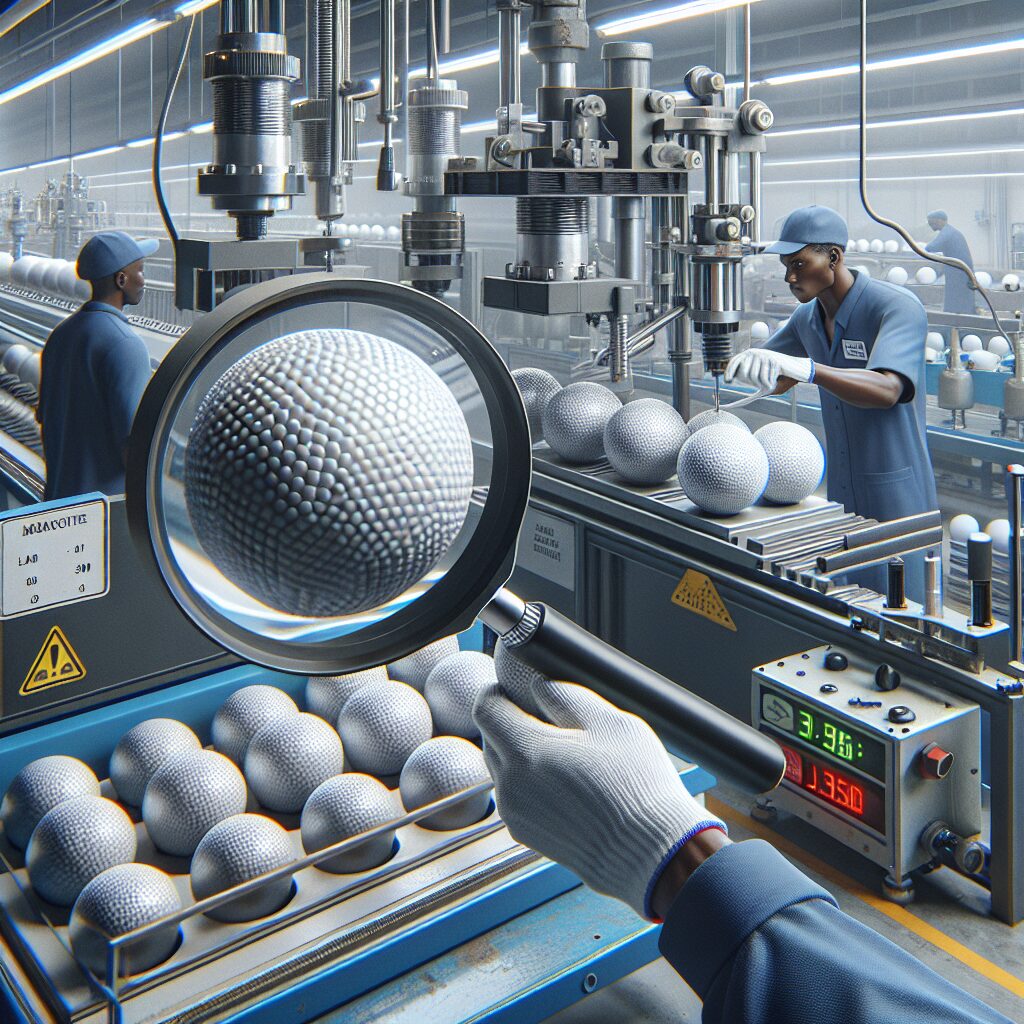

To ensure the quality and reliability of balls, rigorous testing procedures are crucial. These procedures involve testing the balls for various factors, including size, weight, bounce, grip, and overall performance. Testing should be conducted in a controlled environment and follow standardized protocols to ensure consistency. By utilizing advanced testing equipment and techniques, manufacturers can identify any discrepancies, rectify them, and deliver high-quality balls to the market.

Implementing Quality Control Checks

In addition to testing, quality control checks play a vital role in raising the bar for balls. These checks involve inspecting the manufacturing process at various stages to identify any potential deviations from the desired quality standards. From raw material inspection to quality control during the different manufacturing stages, these checks ensure that every aspect of ball production adheres to the defined parameters. By implementing stringent quality control measures, manufacturers can identify and address issues promptly.

Continuous Improvement and Feedback Loop

To further enhance the quality assurance measures for balls, establishing a continuous improvement process is imperative. This involves gathering feedback from athletes, coaches, and users to understand their experiences, suggestions, and concerns. Analyzing this feedback and incorporating necessary improvements into the manufacturing process establishes a feedback loop that ensures continuous enhancement of ball quality. By actively seeking and implementing feedback, manufacturers can raise the bar and deliver even better balls to the market.

How can you Ensure Effective Quality Assurance Measures for Raising the Bar for Balls?

1. Standardize the selection of materials, considering factors like strength, flexibility, and resistance.

2. Establish rigorous testing procedures to evaluate key performance parameters such as size, weight, bounce, and grip.

3. Implement stringent quality control checks at each stage of the manufacturing process.

4. Continuously gather feedback from athletes and users to understand their experiences and suggestions.

5. Analyze feedback and incorporate necessary improvements to enhance the quality of balls over time.

Frequently Asked Questions

1. What are quality assurance measures for balls?

Quality assurance measures for balls are a set of procedures and techniques implemented to ensure that the balls meet specific quality standards. These measures include thorough inspections, testing, and adherence to strict manufacturing guidelines.

2. Why are quality assurance measures important for balls?

Quality assurance measures are crucial for balls to maintain their performance, durability, and safety. By implementing these measures, manufacturers can identify and rectify any flaws or defects in the production process, ensuring that only high-quality balls reach the market.

3. How are quality assurance measures implemented?

Quality assurance measures are implemented through a combination of steps, including raw material quality checks, in-process quality checks, and final product inspections. Additionally, thorough testing for specific performance criteria, such as bounce, weight, and durability, is conducted to ensure the balls meet the required standards.

4. What are the benefits of stringent quality assurance measures?

S stringent quality assurance measures bring several benefits, including enhanced product quality, increased customer satisfaction, improved brand reputation, reduced product returns, and minimized risk of accidents or injuries due to faulty balls.

5. Are there any industry standards for quality assurance measures in ball manufacturing?

Yes, the ball manufacturing industry adheres to various international and national standards to ensure quality. These standards may include specifications for material composition, size, weight, performance characteristics, and testing procedures.

6. How do quality assurance measures impact the cost of balls?

While implementing quality assurance measures may increase the production cost of balls, it ultimately leads to higher product quality and reduced costs associated with product recalls, warranty claims, and customer dissatisfaction. Therefore, the long-term benefits outweigh the initial investment.

7. Can quality assurance measures be applied to all types of balls?

Yes, quality assurance measures can be applied to various types of balls, including sports balls, industrial balls, recreational balls, and precision balls. Each type may have specific quality criteria, and manufacturers can customize their quality assurance measures accordingly.

8. Who is responsible for conducting quality assurance measures for balls?

The responsibility for conducting quality assurance measures lies with the ball manufacturers. They typically have dedicated quality control teams or departments that oversee and enforce these measures during the production process.

9. How often should quality assurance measures be conducted?

Quality assurance measures should be conducted consistently throughout the ball manufacturing process. Regular inspections, testing, and audits are necessary to maintain a high level of quality and ensure that any deviations or issues are promptly addressed.

10. Can consumers play a role in ensuring quality assurance measures for balls?

While consumers cannot directly control the implementation of quality assurance measures, they can play a role in choosing reputable brands and manufacturers known for their commitment to quality. By selecting reliable products and providing feedback, consumers can indirectly influence the industry’s adherence to quality standards.

Final Thoughts: Quality Assurance Measures for Balls

Quality assurance measures play a vital role in raising the bar for balls. By subjecting every ball to rigorous inspections, testing, and adherence to industry standards, manufacturers can ensure that each ball represents the highest level of quality. These measures provide peace of mind to consumers, knowing that they are purchasing reliable and safe balls that will withstand regular use. As the demand for quality increases, it is crucial for manufacturers to continue investing in and improving their quality assurance measures to exceed customer expectations and maintain their competitiveness in the market.

In conclusion, enhancing quality assurance measures for balls not only benefits manufacturers, but also end users and the industry as a whole. By raising the bar for balls, we can create a culture of excellence, where quality becomes the norm rather than the exception. It is an ongoing process that requires continuous improvement, collaboration, and a shared commitment to providing the best possible balls to customers worldwide.