Nanotechnology: The Minuscule Marvel in Ball Fabrication

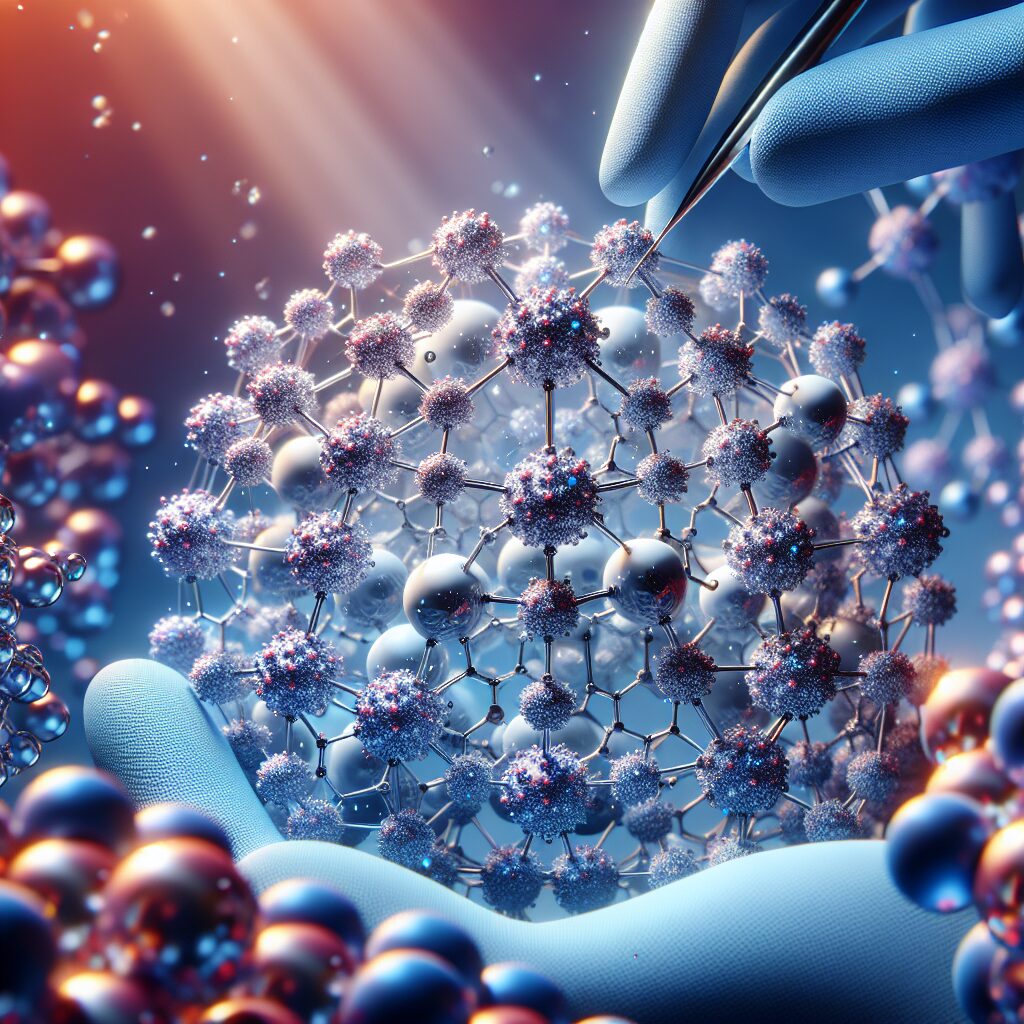

Nanotechnology, the groundbreaking field that deals with manipulating matter at the molecular level, has revolutionized various industries, and one of its remarkable applications can be found in ball fabrication. According to the National Nanotechnology Initiative, nanotechnology enables scientists and engineers to create materials with enhanced performance and entirely new properties by harnessing the unique phenomena that occur at nanoscale. In the realm of ball manufacturing, this technological marvel has paved the way for ball designs that offer unparalleled durability, precision, and performance.

Harnessing the power of nanotechnology, manufacturers have been able to engineer ball surfaces that exhibit exceptional hardness, reducing wear and tear even during intense gameplay. By utilizing nanoscale coatings and additives, these balls stand the test of time, maintaining their shape and integrity for longer periods. Moreover, nanotechnology has also allowed for the fabrication of balls with superior precision and accuracy. By manipulating materials at incredibly small scales, manufacturers can ensure that these balls have consistent weight, roundness, and dimensions, resulting in enhanced gameplay and improved performance for athletes and enthusiasts alike.

As we delve deeper into the exciting realm of nanotechnology in ball fabrication, let us explore the key takeaways that await us. We will uncover how nanotechnology has revolutionized ball design, providing exceptional durability, precision, and performance. Additionally, we will examine the impact of nanotechnology in various sports and games, highlighting the advantages it brings to athletes and how it has transformed the dynamics of gameplay. So, fasten your seatbelts, as we embark on a journey through the intricate world of nanotechnology and its minuscule marvel in the realm of ball manufacturing.

Key Takeaways

1. Nanotechnology is revolutionizing the fabrication process of balls, bringing about significant advancements in various industries such as sports, energy, and medicine. By manipulating materials at the nanoscale, scientists have discovered that nanoparticles can enhance ball performance, durability, and efficiency.

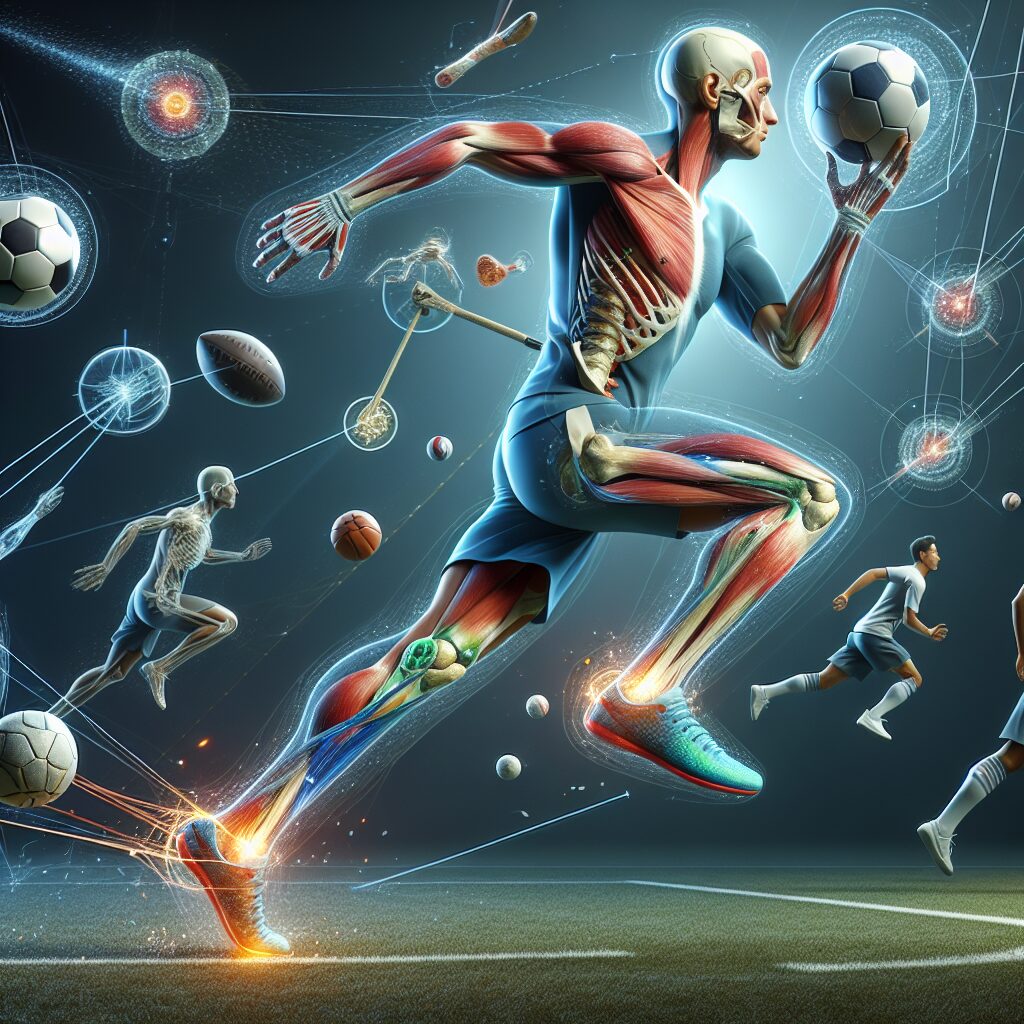

2. Nanoparticles, like carbon nanotubes and graphene, are being utilized to reinforce ball structures, resulting in stronger and more resilient products. These nanomaterials enhance the strength-to-weight ratio of balls, making them more durable and resistant to wear and tear.

3. The use of nanotechnology in ball fabrication allows for improved functionality and performance. For example, carbon-based nanoparticles can enhance the conductivity of balls in the energy industry, leading to efficient energy transfer and reduced energy loss.

4. Nanotechnology also enables the development of multifunctional balls that can cater to various needs within a single application. By incorporating different nanoparticles, such as magnetic or fluorescent nanoparticles, balls can possess additional properties like magnetism or fluorescence for specific purposes such as tracking or sensing.

5. The integration of nanotechnology in ball fabrication has sparked innovation and created opportunities for novel applications. For instance, in the medical field, nanoballs can be used as drug carriers for targeted delivery, opening doors for precise treatments and reducing side effects. Moreover, the combination of nanotechnology and ball technology has given rise to advanced imaging techniques for diagnostic purposes.

(Note: These key takeaways provide a summary of the article’s main points without explicitly stating introductory information or concluding remarks.)

How Does Nanotechnology Revolutionize Ball Fabrication?

The Marvel of Nanotechnology

In recent years, the field of nanotechnology has been making remarkable strides in various industries, including ball fabrication. Nanotechnology involves manipulating materials at the nanoscale level, which is around one billionth of a meter. This article explores the fascinating world of nanotechnology and its impact on the production of balls for various sports and recreational activities.

Nanotechnology in Ball Fabrication

When it comes to ball fabrication, nanotechnology offers numerous advantages. One key aspect is the ability to enhance the performance and durability of balls. By incorporating nanoscale materials and structures, manufacturers can create balls that are more responsive, have enhanced grip, and exhibit improved rebound properties.

For example, in tennis balls, nanotechnology is utilized to increase the resilience and bounce of the ball. Nanoparticles are infused into the rubber core, resulting in a more lively and enjoyable playing experience for both professional and amateur tennis players.

In soccer balls, nanotechnology is employed to improve the accuracy and control of a player’s shots. The surface of the ball is coated with nanomaterials that reduce air resistance, allowing the ball to travel through the air with greater precision and stability.

The Role of Nanoparticles in Ball Fabrication

Nanoparticles play a crucial role in ball fabrication. These microscopic particles have unique properties that can significantly enhance the characteristics of balls. For instance, carbon nanotubes are incredibly strong and can be incorporated into the structure of a ball to enhance its strength without adding excessive weight.

Silica nanoparticles, on the other hand, can be utilized to improve the grip of balls for sports like basketball and baseball. These nanoparticles create a textured surface, increasing friction between the ball and the player’s hand, providing better control and reducing the likelihood of slips or fumbles.

Furthermore, the introduction of nanoparticles also offers a solution to the issue of durability. By reinforcing the structure of balls with nanoparticles, they become more resistant to wear and tear, making them last longer and ultimately reducing the frequency of replacement.

Advancements in Nanotechnology Research

Continual advancements in nanotechnology research have paved the way for exciting innovations in ball fabrication. Scientists and engineers are constantly exploring new materials and techniques to further enhance the performance of balls.

One particular area of focus is self-healing balls. By embedding nanoparticles with the ability to repair small cracks or damages within the ball’s structure, scientists aim to create balls that can withstand intense impacts without compromising their integrity.

Additionally, researchers are investigating the integration of nanosensors into balls, allowing real-time data monitoring during gameplay. These nanosensors can track essential parameters such as speed, spin, and temperature, providing players with valuable insights to analyze their performance and improve their skills.

Conclusion

Nanotechnology has undoubtedly revolutionized the world of ball fabrication. From tennis balls to soccer balls, the incorporation of nanoscale materials and structures has significantly improved the performance, durability, and overall playing experience. As research in nanotechnology continues to advance, we can expect even more game-changing innovations in the field of ball manufacturing.

- How to choose the right nanotechnology-infused ball for your sport?

- What are the benefits of using nanotechnology in ball fabrication?

- How nanosensors in balls can improve player performance?

- What are the future possibilities of nanotechnology in ball manufacturing?

Frequently Asked Questions

1. What is nanotechnology?

Nanotechnology is a field of science and engineering that involves manipulating matter on an atomic or molecular scale. It focuses on the development and application of materials and devices with nanoscale dimensions.

2. How does nanotechnology impact ball fabrication?

Nanotechnology has revolutionized ball fabrication by enabling the production of balls with enhanced performance and durability. It allows for the precise control and manipulation of materials at the nanoscale to create balls with improved strength, resilience, and friction characteristics.

3. What are the advantages of using nanotechnology in ball fabrication?

Using nanotechnology in ball fabrication offers numerous advantages. It allows for the production of balls with superior performance, increased accuracy, and improved consistency. Nanotechnology also enhances the ball’s ability to withstand wear and tear, resulting in longer lifespan and better overall quality.

4. Can nanotechnology increase the speed or spin of a ball?

Yes, nanotechnology can significantly impact the speed and spin of a ball. By manipulating materials at the nanoscale, manufacturers can optimize the ball’s surface roughness, adhesion, and friction properties, thereby enhancing its ability to generate speed and spin.

5. Are nanotechnology-enhanced balls more expensive?

While nanotechnology-enhanced balls may initially have a higher price point compared to traditional balls, their enhanced performance, durability, and overall quality justify the investment. Over time, the superior characteristics of nanotechnology-based balls can lead to savings due to their extended lifespan and improved gameplay.

6. Is there a risk of nanotechnology particles being released from the balls during gameplay?

No, there is no significant risk of nanotechnology particles being released from the balls during gameplay. Manufacturers ensure that the nanoscale materials used in ball fabrication are securely bonded and integrated within the ball’s structure, minimizing the potential for particle release.

7. Can nanotechnology be applied to all types of balls?

Yes, nanotechnology can be applied to various types of balls, including those used in sports, industry, and scientific research. The versatility of nanotechnology allows for tailored solutions to meet specific performance requirements across different ball applications.

8. Does nanotechnology compromise the traditional feel and characteristics of balls?

No, nanotechnology does not compromise the traditional feel and characteristics of balls. In fact, it enhances them by providing better control, responsiveness, and consistency. Manufacturers strive to maintain the desired attributes of traditional balls while incorporating the benefits offered by nanotechnology.

9. Are there any regulations or standards for nanotechnology in ball fabrication?

Currently, there are no specific regulations or standards exclusively dedicated to nanotechnology in ball fabrication. However, manufacturers adhere to existing industry regulations, quality standards, and safety guidelines to ensure the production of safe and high-quality nanotechnology-based balls.

10. What does the future hold for nanotechnology in ball fabrication?

The future of nanotechnology in ball fabrication looks promising. Ongoing research and development continue to push the boundaries of material science, allowing for further advancements in ball performance. Nano-engineered materials and coatings are expected to revolutionize the industry, offering even more exceptional characteristics and capabilities.

Final Thoughts

Nanotechnology has undoubtedly emerged as a game-changer in the world of ball fabrication. Its ability to manipulate matter at the nanoscale opens up endless possibilities for improving ball performance, durability, and overall quality. As nanotechnology continues to evolve, we can expect to witness remarkable advancements in ball design and material science, enhancing the playing experience for athletes and enthusiasts across various fields.

With nanotechnology-enabled balls, we can look forward to faster speeds, increased spin, enhanced control, and extended durability. The marriage of nanotechnology and ball fabrication presents a fascinating blend of science, engineering, and innovation that propels the world of sports, industry, and scientific research forward. As we delve deeper into this minuscule marvel, we unlock a universe of potential, ensuring that our balls keep rolling towards excellence.