Cricket is much more than just a bat and a ball – it is a game steeped in tradition, strategy, and skill. While the players on the field are undoubtedly the stars of the show, the cricket ball itself plays an equally important role in the game. Materials Matter: The Science of Cricket Ball Making delves into the intricate world of cricket ball manufacturing, exploring the fascinating science behind this crucial piece of equipment.

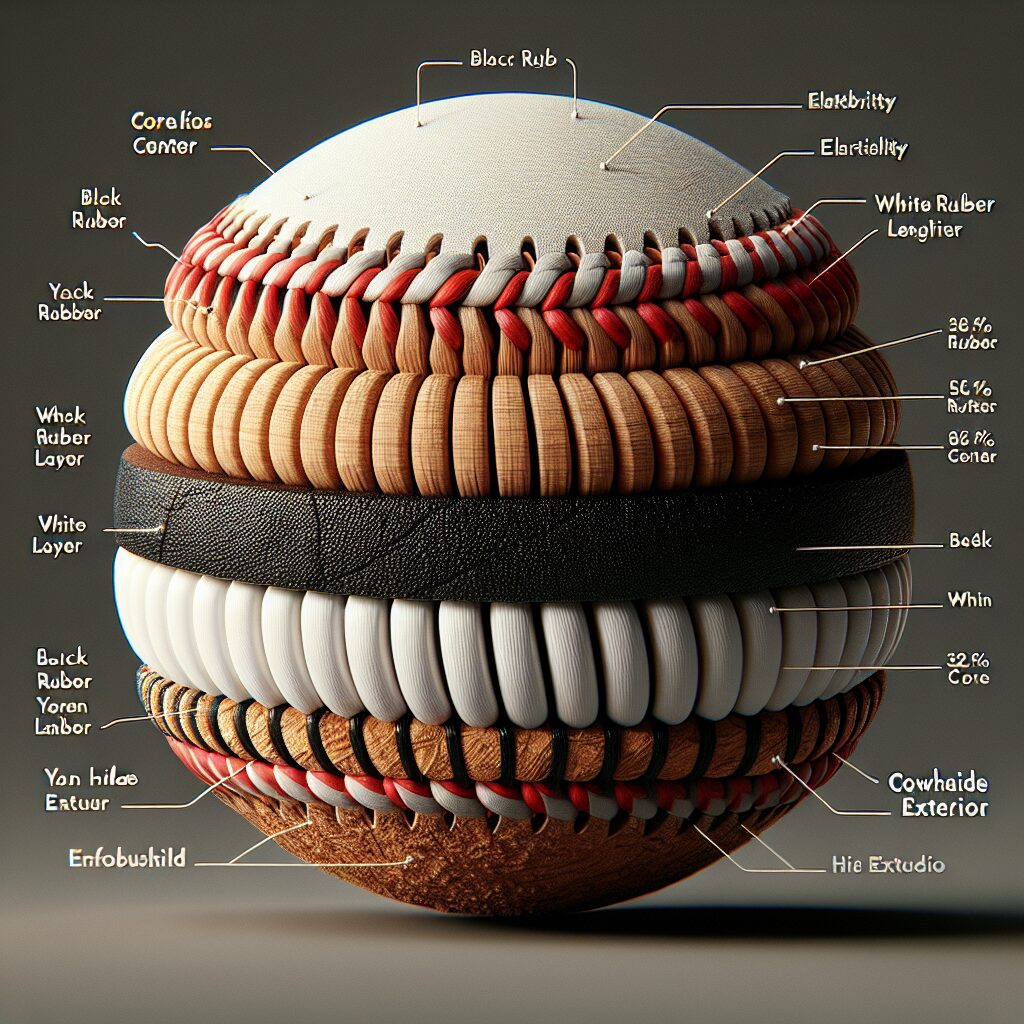

The cricket ball may seem like a simple sphere, but its construction involves a meticulous process that has been refined over centuries. From the outer leather casing to the cork and wool core, each component is carefully selected to ensure optimal performance on the pitch. The type of leather used, the stitching pattern, and even the methods of polishing and lacquering all contribute to the ball’s behavior during play. By understanding the materials and techniques involved, we gain valuable insights into the impact they have on the trajectory, swing, and spin of the ball.

In the upcoming sections, we will delve into the key takeaways of the science of cricket ball making. We will explore how the choice of materials affects the ball’s bounce and durability, as well as its ability to grip the surface and generate movement in the air or off the pitch. Furthermore, we will uncover the intricate details of the manufacturing process, discussing the various stages involved and the careful craftsmanship required at each step. So, let us embark on this fascinating journey into the world of cricket ball making and discover the secrets that lie within this seemingly simple sphere.

Key Takeaways

– The materials used in cricket ball making greatly impact the ball’s performance and playability.

– The core of the cricket ball is made from cork and is vital in determining the ball’s bounce and durability.

– The cork is surrounded by multiple layers of twine and leather, which contribute to the ball’s shape, weight, and grip for the bowler.

– The manufacturing process of a cricket ball involves meticulous stitching by hand, with certain stitching techniques giving the ball a characteristic swing.

– The selection and preparation of materials used in cricket ball making are crucial to ensure consistency, fair play, and optimal performance in the game.

What is the Science Behind Cricket Ball Making?

The science behind cricket ball making is a fascinating topic that delves into the materials used and the intricate manufacturing process. From the core to the outer layers, each component is carefully designed to meet certain specifications and ensure optimal performance on the cricket field.

The Core: A Solid Foundation

The core of a cricket ball is typically made of cork, which is known for its resilience and ability to retain its shape. Cork provides the necessary weight and bounce to the ball, allowing it to be bowled effectively. However, simply using cork alone would result in an unpredictable flight path and inadequate durability.

Winding the Layers: Reinforcement and Stability

To enhance the core’s stability and durability, multiple layers of tightly wound string are added. Traditionally, the string was made of thin cotton, but modern manufacturing techniques have introduced more advanced materials such as polyester. This winding process helps the ball maintain its shape and resist deformation even when subjected to intense impact.

The Outer Shell: Leather and its Treatment

The outermost layer of a cricket ball is made from high-quality leather, typically sourced from bovine hide. The leather is carefully chosen for its strength, durability, and ability to provide grip for spin bowlers. However, raw leather alone is not suitable for cricket ball usage.

The leather undergoes an extensive treatment process, including dyeing and polishing, to improve its performance characteristics. Reducing the surface roughness and applying polish not only enhances the ball’s aerodynamics but also ensures optimum grip when the ball comes into contact with the pitch.

Regulation Standards and Quality Control

Cricket balls must adhere to strict regulations set by the International Cricket Council (ICC). The weight, circumference, and bounce of the ball must meet specific criteria to ensure a fair game. Quality control measures are in place to test each ball’s performance and durability before it reaches the hands of players.

Ongoing Research and Development

The science of cricket ball making is an ongoing process, with researchers continually exploring new methods and materials to enhance performance and durability. Technologies such as computer simulations and advanced data analysis assist in understanding how different materials and designs affect the ball’s behavior.

Numbered Tips for Making High-Quality Cricket Balls

1. What are the key characteristics of cork used in the core of a cricket ball?

2. How does winding multiple layers of string strengthen the ball’s core?

3. What are the main considerations when choosing the leather for the outer shell?

4. Why is surface treatment crucial for a cricket ball’s performance?

5. How does the ICC ensure standardization and quality control in cricket ball manufacturing?

6. What advancements in materials and design have contributed to improved cricket ball performance?

7. How can computer simulations and data analysis assist in the research and development of cricket ball making?

Materials Matter: The Science of Cricket Ball Making – FAQ

1. What materials are commonly used to make cricket balls?

Cricket balls are typically made using a core made of cork layered with tightly wound string and covered with a leather exterior.

2. How does the material used affect the performance of a cricket ball?

The materials used in a cricket ball greatly impact its performance. The type and quality of the cork core, the tightness of the wound string layers, and the quality of the leather covering all contribute to factors such as bounce, swing, and durability.

3. Why is cork used as the core material?

Cork is used as the core material in cricket balls because it provides the necessary weight, resilience, and bounce. It also allows the ball to retain its shape and provides a consistent response when bounced or hit.

4. How do the string layers affect the ball’s performance?

The tightly wound string layers in a cricket ball contribute to its shape retention, weight distribution, and bounce. The number and tightness of the string layers determine the ball’s hardness and how it responds to impact.

5. What role does the leather covering play in a cricket ball?

The leather covering of a cricket ball acts as a protective layer and provides a smooth and consistent surface for the bowlers to grip. It also affects the ball’s aerodynamics, influencing its swing and seam movement through the air.

6. Are there any regulations regarding the materials used in cricket ball making?

Yes, cricket ball manufacturers need to adhere to specific regulations set by cricket governing bodies, such as the International Cricket Council (ICC). These regulations ensure that the materials used and the ball’s overall construction meet the required standards for play.

7. How long does a cricket ball typically last?

The lifespan of a cricket ball can vary depending on various factors, including the pitch conditions and the level of play. In professional matches, a cricket ball is often changed every 80-90 overs due to wear and tear. However, in amateur games, a ball may last for several matches.

8. Can the materials used in cricket ball making affect player safety?

Yes, the materials used play a role in player safety. If a cricket ball is inadequately constructed or uses substandard materials, it may pose a higher risk of injury to players upon impact or during unexpected pitching behavior.

9. Are there any ongoing research or advancements in cricket ball materials?

Yes, there are continuous efforts to improve cricket ball materials. Research is being conducted to develop materials that offer enhanced durability, bounce, swing, and seam movement. Scientists and manufacturers work together to find ways to balance tradition with modern advancements.

10. How can the knowledge about cricket ball materials benefit players and coaches?

Understanding cricket ball materials can help players and coaches make informed decisions on ball selection based on playing conditions, player skill level, and desired performance characteristics. It also allows for better training and preparation, enabling players to adapt their techniques accordingly.

Final Thoughts: The Science of Cricket Ball Making

The science behind cricket ball making is a fascinating field that intertwines tradition and innovation. The meticulous selection of materials and the craftsmanship involved in creating these essential components of the game contribute significantly to the performance and excitement of cricket matches. By understanding the science and technology behind ball making, players and enthusiasts gain a deeper appreciation for the nuances of the game and can enhance their skills with this knowledge.

As cricket evolves, so does the pursuit of making better cricket balls. Research on materials and design advancements strives to enhance playing conditions, increase player safety, and add new dimensions to the game. The continued collaboration between scientists, manufacturers, and cricket organizations ensures that cricket balls will always be at the forefront of cricket’s science, contributing to the ongoing development of this beloved sport.