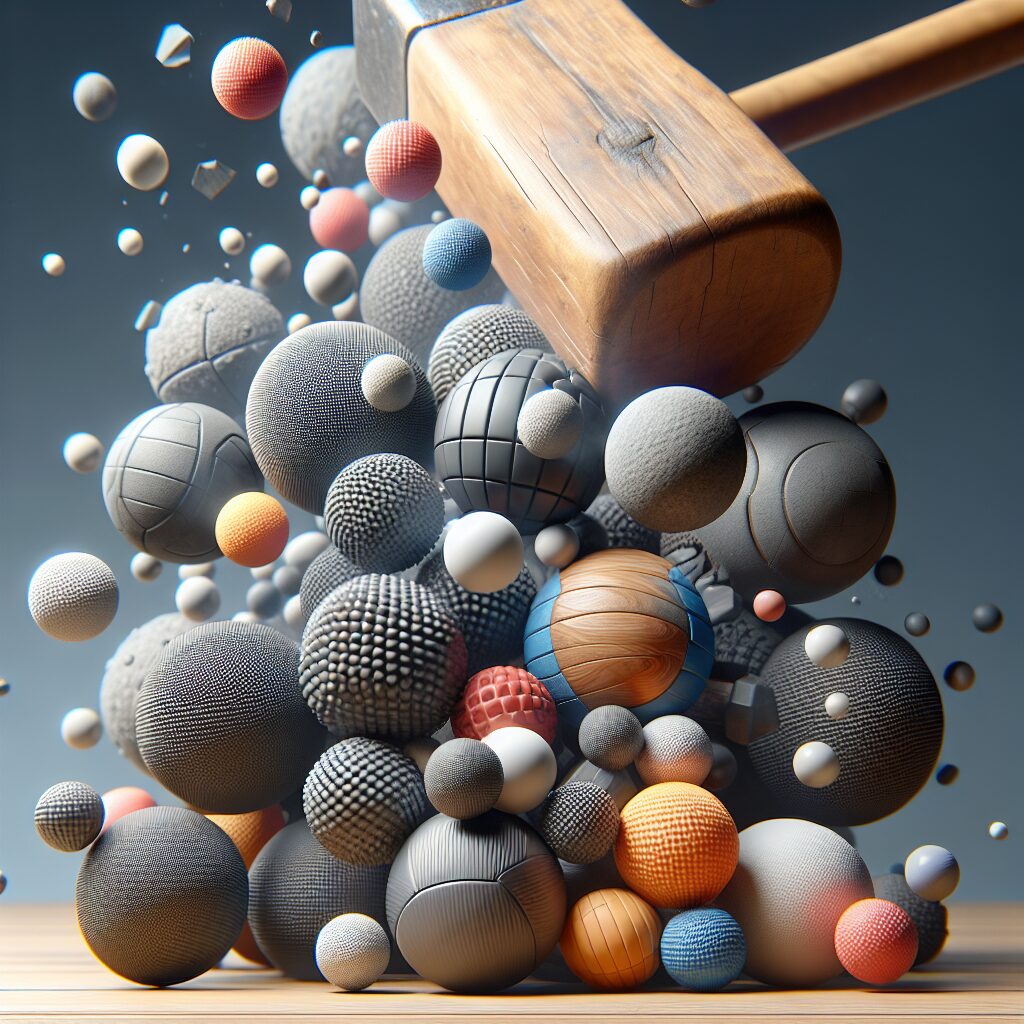

Material durability is a fundamental aspect of creating resilient balls that can withstand the test of time and intense physical activities. When it comes to sports equipment, such as soccer balls, basketballs, or tennis balls, durability is crucial to ensure consistent performance and enhance the overall playing experience. To better understand this concept, it is important to consider the specific impacts and unique features of durable materials in ball manufacturing.

The choice of materials directly affects the durability and longevity of a ball. Manufacturers now utilize various materials, such as synthetic leather, rubber, or polyurethane, to enhance the ball’s resistance to wear and tear. For instance, synthetic leather balls are specifically designed to withstand abrasion and maintain their shape even after prolonged use on different playing surfaces. Rubber balls, on the other hand, offer excellent grip and bounciness, ensuring optimal performance during intense gameplay. By understanding the impact of materials on a ball’s durability, manufacturers can produce sports balls that can withstand the rigors of various sports.

Moving forward, let us delve into the key takeaways regarding material durability in ball production. We will discuss the different materials used in ball manufacturing, their unique properties, and the importance of proper maintenance to ensure the durability of sports balls. Additionally, we will explore how these durable materials impact players’ performance, safety, and overall enjoyment on the field or court. Stay tuned to discover how choosing the right materials can make a significant difference in the resilience and longevity of sports balls.

Key Takeaways

1. Material durability is crucial for building resilient balls that can withstand impact and preserve their shape and performance over time.

2. The traditional composition of tennis balls, which includes a rubber core encased in a fuzzy felt cover, is being challenged by innovative materials and designs that enhance durability.

3. Advances in technology have led to the development of durable materials such as cross-linked polybutadiene, which can improve the lifespan of tennis balls by significantly reducing wear and tear.

4. The durability of soccer balls is being improved through the use of synthetic materials, such as thermoplastic polyurethane, which provide superior resistance to abrasion and impacts.

5. Material durability plays a significant role in the long-term performance and safety of various sports balls, influencing factors such as bounce, accuracy, and injury prevention, making it an area of continuous research and innovation.

How to Build Resilient Balls with Long-Lasting Material Durability?

Understanding the Importance of Material Durability

When it comes to building resilient balls, one crucial factor that cannot be overlooked is material durability. The durability of the materials used in the construction of balls significantly impacts their overall resilience and longevity. Whether you’re manufacturing sports balls or play balls for children, utilizing durable materials ensures that your products can withstand the rigors of use over time. Building resilient balls starts with selecting materials that are designed to endure various environments and conditions.

Choosing the Right materials

The first step in crafting durable balls is selecting the appropriate materials. Depending on the specific application, different materials may be more suitable. For sports balls, materials like synthetic leather, rubber, or high-density polyurethane are commonly used due to their excellent durability and resistance to wear and tear. While for play balls, materials such as thick PVC or TPU can provide the necessary strength for prolonged use. By choosing materials specifically tailored to the intended purpose, you can enhance the overall durability of the balls.

Optimizing Ball Construction

Once you have the right materials, the construction process plays a significant role in ensuring material durability. Employing advanced manufacturing techniques, such as seamless construction or reinforced stitching, can enhance the overall strength and durability of the balls. These techniques minimize the chances of material weakening or seams splitting, increasing the longevity of the final product. Additionally, strategically placing reinforcement panels or layers in high-stress areas, such as the bladder or covering, can also contribute to improving material durability.

Testing and Quality Control

Building resilient balls requires not only a careful selection of materials and optimized construction process but also thorough testing and quality control measures. Implementing stringent quality control protocols throughout the manufacturing process helps to identify any potential weaknesses in the materials or construction early on. By subjecting the balls to rigorous testing, including impact resistance, abrasion testing, and durability assessments, manufacturers can ensure that only the highest quality, longest-lasting balls hit the market.

Taking Care of Resilient Balls

After successfully building resilient balls with excellent material durability, it is essential to educate users on proper care and maintenance. Providing guidelines on how to clean, store, and handle the balls can significantly impact their lifespan. For instance, storing balls in a dry and cool environment, away from direct sunlight, can prevent premature degradation. Similarly, cleaning the balls regularly and avoiding rough surfaces during use can also preserve their durability for an extended period.

Key Tips for Building Resilient Balls with Exceptional Material Durability:

- What materials are best suited for sports balls versus play balls?

- How can advanced manufacturing techniques enhance material durability?

- What testing protocols should be implemented to ensure high-quality balls?

- What care and maintenance practices help maintain the durability of balls?

Frequently Asked Questions

1. What is material durability?

Material durability refers to the ability of a material to withstand wear and tear, impact, and other forms of stress over an extended period. In the context of building resilient balls, it means selecting materials that can withstand repetitive use and maintain their shape and performance.

2. Why is material durability important in building resilient balls?

Material durability is crucial in building resilient balls because it directly affects the longevity and performance of the ball. Durable materials ensure that the balls can withstand intense games, harsh playing surfaces, and environmental factors without losing their shape, bounce, or functionality.

3. Which materials are commonly used for building resilient balls?

The materials commonly used for building resilient balls include rubber, synthetic materials like TPU (thermoplastic polyurethane), polyvinyl chloride (PVC), and composite blends. Each material offers different levels of durability, bounce, and performance, allowing manufacturers to choose the most suitable option for specific sports or purposes.

4. How does the manufacturing process impact material durability?

The manufacturing process plays a significant role in determining the material durability of resilient balls. Factors such as molding techniques, curing processes, material composition, and quality control measures affect the final product’s durability. A well-executed manufacturing process ensures high-quality materials and construction, leading to more durable balls.

5. Are there any standards or certifications for material durability in balls?

Yes, there are various international standards and certifications that assess the material durability of balls. Organizations like the International Organization for Standardization (ISO) and sports governing bodies set specific requirements and conduct tests to ensure balls meet durability standards. Look for certified balls to ensure their resilience and longevity.

6. How can I identify a durable ball?

To identify a durable ball, consider factors such as the materials used, manufacturing reputation, and any certifications it holds. Additionally, reading customer reviews and seeking recommendations from experienced players or coaches can provide insights into the ball’s durability and performance.

7. Can I enhance the durability of a ball through proper maintenance?

Yes, proper maintenance can enhance the durability of a ball. Keeping the ball clean, storing it in a suitable environment, and avoiding exposure to extreme temperatures or sharp objects can help prolong its lifespan and maintain its resilience.

8. How long can a resilient ball typically last?

The lifespan of a resilient ball depends on various factors, including the quality of materials, frequency of use, playing conditions, and level of maintenance. Generally, a well-made and properly cared for resilient ball can last anywhere from several months to a few years.

9. Can material durability affect player safety?

Yes, material durability plays a role in player safety. Balls with poor durability may deteriorate quickly, leading to the risk of sudden deflation or structural failure during play, which can increase the likelihood of accidents or injuries. Opting for resilient balls ensures a safer playing experience.

10. Are resilient balls more expensive than less durable alternatives?

Resilient balls often come at a slightly higher cost than their less durable alternatives. The higher price reflects the use of better-quality materials, advanced manufacturing techniques, and stringent quality control measures that contribute to their durability and performance. However, investing in resilient balls can prove cost-effective in the long run due to their extended lifespan.

Final Thought: The Key to Long-lasting Enjoyment

Building resilient balls with material durability as a priority is vital for both players and manufacturers. When balls are designed to withstand rigorous use and adverse conditions, they provide a consistent and enjoyable experience for players, while also minimizing the need for frequent replacements. Manufacturers must continue to innovate and refine their materials and manufacturing processes to ensure the creation of resilient balls that can withstand the test of time and intensify the passion of the game.

As players, coaches, or enthusiasts, appreciating the significance of material durability and consciously choosing resilient balls supports our safety, performance, and the overall quality of our sports activities. By acknowledging the role of material durability in building resilient balls, we contribute to a culture that values excellence, longevity, and sustainability in sports equipment.