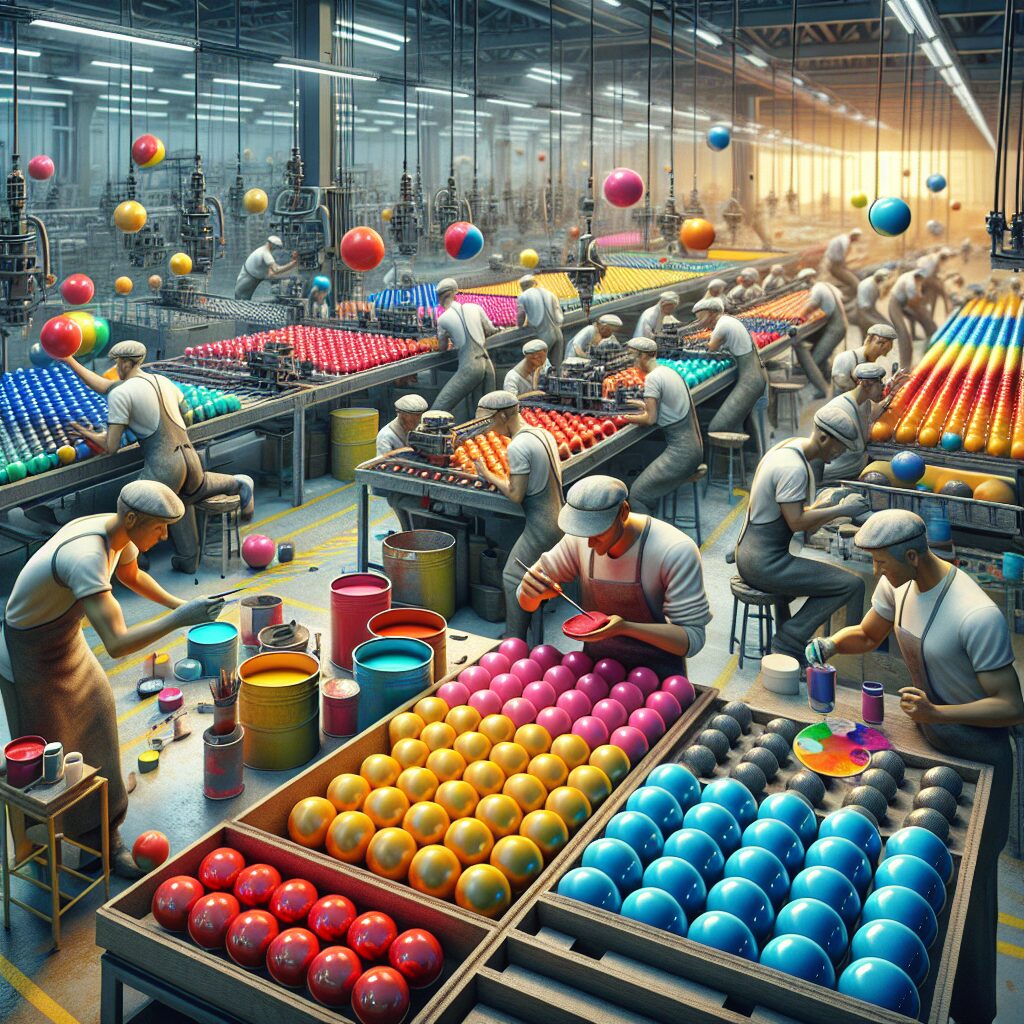

Mastering Ball Painting Techniques in Manufacturing is a crucial aspect in producing high-quality products. Ball painting refers to the process of applying paint or coating on surfaces of spherical objects, such as metal balls or bearings, to enhance their appearance, protect against corrosion, and improve durability. This technique plays a significant role in various industries, including automotive manufacturing, aerospace engineering, and even sports equipment production. With precise ball painting techniques, manufacturers can achieve consistent and even coating distribution, ensuring a visually appealing and long-lasting finish. In this article, we will explore the key takeaways to help you understand the intricacies of mastering ball painting techniques in manufacturing and how it can benefit your product outcomes.

One unique insight associated with ball painting techniques is the use of advanced technologies for surface preparation, application, and drying processes. Prior to applying the paint or coating, the surfaces of the balls need to be thoroughly cleaned and prepared to ensure proper adhesion and smooth finish. Manufacturers often employ methods such as grit blasting or chemical treatment to achieve the desired surface roughness and cleanliness. Furthermore, modern manufacturing facilities utilize automated systems that ensure precise application of the coating material, preventing excessive or uneven paint distribution. To accelerate drying times and increase efficiency, some manufacturers also employ specialized drying ovens or infrared drying techniques. These advanced technologies contribute to improved productivity, reduced waste, and enhanced overall quality in ball painting processes.

Moving forward, let’s delve into the key takeaways that will aid in mastering ball painting techniques in manufacturing. We will discuss the importance of surface preparation, the role of paint or coating selection, the significance of proper application techniques, and the advantages of using automated systems. By understanding these key factors, manufacturers can optimize their ball painting processes to achieve superior results and meet the demands of their customers. Stay tuned for the following sections, where we will delve deeper into each of these key takeaways and provide valuable insights and guidelines to help you excel in ball painting techniques.

Key Takeaways

1. Proper surface preparation is essential for achieving successful ball painting in manufacturing. Cleaning, sanding, and priming the balls prior to painting ensures proper adhesion and a smooth finish.

2. Selecting the appropriate type of paint and brushes or spray guns is crucial for achieving desired results. Water-based or oil-based paints, along with high-quality brushes or spray guns, allow for smooth application and long-lasting durability.

3. Technique plays a significant role in achieving evenly coated and professionally finished balls. Applying thin layers of paint in multiple coats, using smooth and consistent strokes, and allowing proper drying time between coats ensures a flawless paint finish.

4. Variations in colors and designs can be achieved through techniques such as masking, stenciling, or tape application. These methods allow for precise and intricate patterns, resulting in customized and visually appealing painted balls.

5. Proper maintenance and storage of painted balls is necessary to preserve their longevity and beauty. Regular cleaning, avoiding excessive handling or impact, and storing in a cool and dry environment help prevent paint chipping, fading, or peeling over time.

What are the Essential Steps to Master Ball Painting Techniques in Manufacturing?

Understanding the Importance of Ball Painting in Manufacturing

Ball painting is a crucial process in manufacturing, especially in industries like automotive, aerospace, and sports equipment. This technique involves applying a protective or decorative coating on spherical objects, such as ball bearings, balls used in sports, or components of machinery. The paint not only enhances the aesthetic appeal but also provides a protective layer against corrosion, wear, and tear. To ensure a flawless finish, it is essential to master the ball painting techniques in manufacturing.

Preparation and Surface Cleaning

Before starting the ball painting process, thorough preparation is necessary to achieve optimal results. This involves cleaning the surface of the balls to remove any contaminants, grease, or dirt. Proper cleaning helps the paint adhere to the surface evenly and prevents any imperfections. Use specialized cleaning agents or solvents recommended for the specific type of material used in the balls. Ensure that the balls are completely dry before moving on to the next step.

Priming the Balls

Priming the balls is an essential step to ensure excellent adhesion and durability of the paint. Apply a thin layer of primer designed for the material of the balls. The primer acts as a base coat, providing a smooth and even surface for the subsequent layers of paint. It also enhances the color intensity and improves the overall finish. Follow the manufacturer’s instructions for the appropriate drying time before moving on to the next step.

Choosing the Right Paint and Application Method

Selecting the right type of paint is vital to achieve the desired results in ball painting. Consider the material of the balls, the environment they will be exposed to, and the specific requirements of the finished product. Choose a paint formulation that provides excellent adhesion, durability, and resistance to scratches, chemicals, and UV rays. Additionally, select the appropriate application method, such as spray painting, dipping, or airbrushing, based on the size, quantity, and complexity of the balls.

Mastering Painting Techniques

To achieve a flawless finish, mastering various painting techniques is crucial. Consistency, control, and precision are key elements to ensure an even coat of paint with no drips, runs, or uneven spots. Practice proper spraying or brushing techniques, maintaining a suitable distance from the balls to avoid over-painting or under-painting. Use smooth, overlapping strokes or circular motions for even application and coverage. Experiment with different techniques to achieve unique effects or patterns if desired.

Drying and Curing

After the paint application, proper drying and curing are essential to achieve a durable and long-lasting finish. Place the painted balls in a controlled environment with adequate ventilation and temperature for optimal drying. Follow the instructions provided by the paint manufacturer for the recommended drying time. Allow sufficient curing time before subjecting the balls to any further handling or assembly processes.

Numbered Guides for Mastering Ball Painting Techniques in Manufacturing:

1. How to properly clean the surface of the balls before painting?

2. What type of primer should be used and how to apply it effectively?

3. Which paint formulation is suitable for different materials and environmental conditions?

4. What are the various application methods and when to use each of them?

5. What are the essential tips for achieving consistency and precision in painting techniques?

6. How to ensure proper drying and curing for a durable finish?

Remember, mastering ball painting techniques in manufacturing is a continuous learning process. Practice, experimentation, and staying updated with the latest paint technologies and equipment are essential to achieve exceptional results.

Frequently Asked Questions

What are some commonly used ball painting techniques in manufacturing?

There are several ball painting techniques commonly used in manufacturing, including spray painting, dip coating, electrostatic painting, and stencil painting. Each technique offers unique advantages and is suitable for different applications and desired outcomes.

Can ball painting techniques be automated?

Yes, ball painting techniques can be automated. In fact, automation is widely utilized in manufacturing industries to enhance efficiency, consistency, and accuracy in the painting process. Robotic systems can be programmed to perform precise and repetitive movements, resulting in superior paint quality and reduced cycle times.

How can I ensure proper adhesion of paint on the ball surface?

To ensure proper adhesion of paint on the ball surface, it is crucial to ensure the surface is clean and free of any contaminants. Pre-treatment processes such as cleaning, sandblasting, or applying primers can enhance the adhesion properties of the ball. Additionally, using the appropriate type of paint for the specific material of the ball is essential for ensuring strong adhesion.

What are the factors that affect the drying time of painted balls?

The drying time of painted balls can be influenced by several factors, including the type of paint used, ambient temperature, humidity levels, airflow, and the thickness of the paint layer. Generally, higher temperatures and lower humidity levels facilitate faster drying, whereas thicker paint layers and high humidity can extend the drying time.

Are there any environmental considerations in ball painting techniques?

Yes, there are environmental considerations in ball painting techniques. Many manufacturers now prioritize using eco-friendly and low-VOC (volatile organic compounds) paints to minimize the impact on the environment. Additionally, proper waste management and disposal practices are essential to prevent pollution and comply with environmental regulations.

How can I achieve a glossy or matte finish on painted balls?

To achieve a glossy finish on painted balls, a clear topcoat or a gloss-enhancing paint can be applied after the base paint has dried. For a matte finish, a matte topcoat or a specific matte paint can be used. The desired finish can be achieved by selecting the appropriate products and following the application instructions provided by the paint manufacturer.

What safety precautions should be taken during ball painting?

When engaging in ball painting, it is important to prioritize safety. Wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and masks, is crucial to protect against potential hazards associated with paint fumes and chemical exposure. Proper ventilation in the painting area is also essential to maintain a safe working environment.

Can different colors be applied to the same ball?

Yes, different colors can be applied to the same ball using various ball painting techniques. Manufacturers often use masking and stenciling methods to achieve precise color patterns or apply multiple colors. These techniques enable customization and branding, allowing balls to be painted with different colors or designs according to specific requirements.

What maintenance is required for painted balls?

To maintain the appearance and durability of painted balls, regular cleaning and proper handling are recommended. Harsh chemicals and abrasive cleaners should be avoided as they can damage the paint finish. Gentle cleaning with mild soaps or specified cleaning solutions, along with appropriate storage and handling practices, will help prolong the lifespan and quality of the painted balls.

How can I learn more about mastering ball painting techniques in manufacturing?

To delve deeper into mastering ball painting techniques in manufacturing, it is advantageous to seek specialized training or attend workshops specific to industrial painting processes. Additionally, online resources, industry publications, and engaging in discussions with industry experts can provide valuable insights and knowledge in this field.

Final Thoughts

Mastering Ball Painting Techniques in Manufacturing:

Mastering ball painting techniques in manufacturing is crucial for achieving high-quality and visually appealing painted balls. With the right combination of technique, equipment, and materials, manufacturers can transform ordinary balls into customized products, enhancing their value and appeal in various industries. From selecting the appropriate paints to implementing proper application methods, attention to detail and adherence to safety standards are essential throughout the entire painting process. By continuously exploring and refining these techniques, manufacturers can elevate their ball painting capabilities, providing innovative and eye-catching solutions to meet market demands.