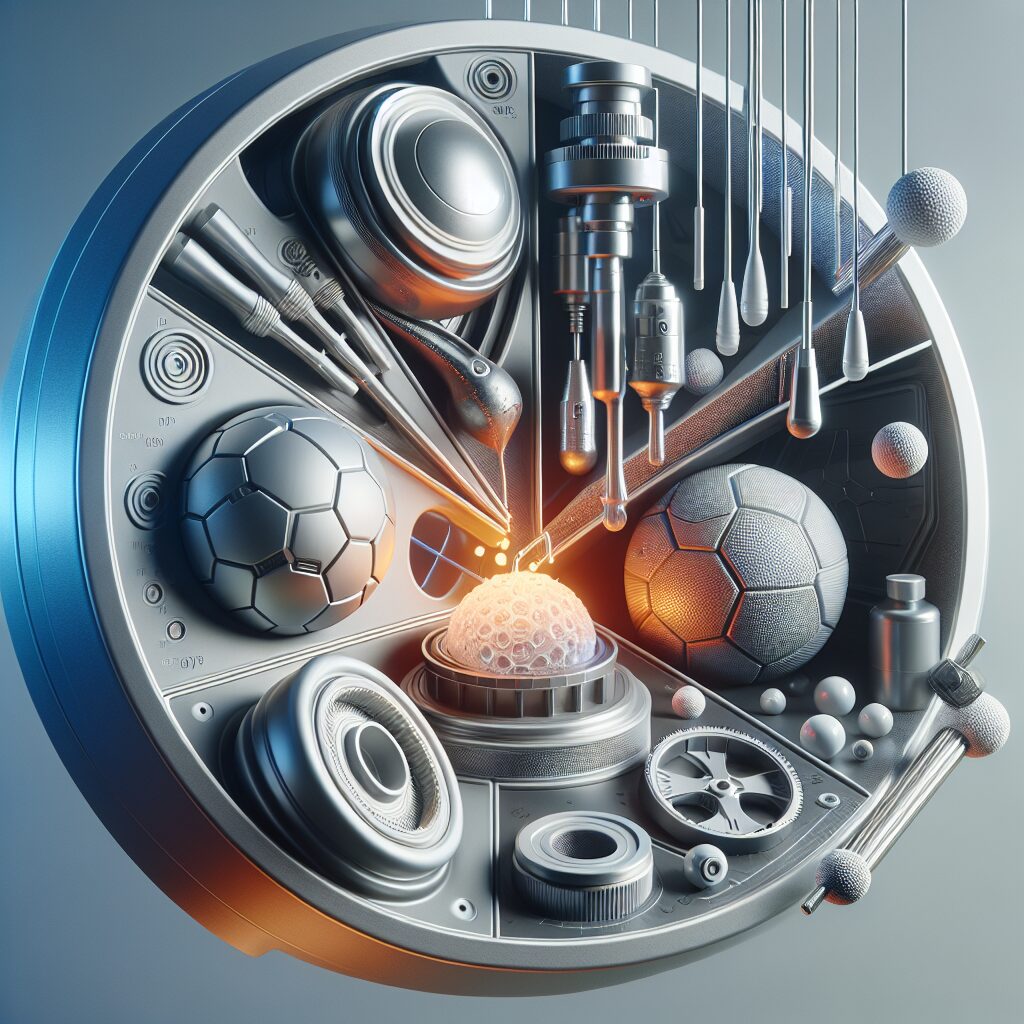

Innovative molding techniques have revolutionized the art of ball fabrication, offering new possibilities and pushing boundaries in various industries. Molding refers to the process of shaping or forming a material into a desired shape or form. In the context of ball fabrication, it involves creating perfectly spherical objects with precise dimensions and properties.

One unique fact about innovative molding techniques for ball fabrication is their ability to produce balls of varying sizes, ranging from miniature balls used in medical devices to large balls used in sports equipment. This versatility opens up a world of opportunities for manufacturers who require spherical objects in their products. Moreover, innovative molding techniques allow for the creation of balls with complex and intricate designs, incorporating multiple materials, textures, and patterns.

Moving forward, let’s delve into the key takeaways of this article. We will explore the various innovative molding techniques used in ball fabrication, their specific impacts in different industries, and the advantages they offer over traditional manufacturing methods. Additionally, we will discuss the challenges faced in implementing these techniques and how they are being addressed. By the end of this article, you will have gained valuable insights into the art of ball fabrication and the transformative power of innovative molding techniques.

Key Takeaways

1. Molding techniques for ball fabrication have evolved to meet the demand for complex and customized designs, offering greater design freedom and improved functional capabilities.

2. Various innovative methods, such as rotational molding, injection molding, and thermoforming, enable the production of balls with diverse materials, sizes, and textures, allowing for greater versatility in applications across industries.

3. Advanced technologies, like 3D printing and computer numerical control (CNC) machining, are increasingly employed in ball fabrication to achieve intricate designs, superior accuracy, and shorter lead times, revolutionizing the manufacturing process.

4. The integration of smart materials and nanotechnology into ball production provides unprecedented functionalities, such as self-healing, sensing, and energy harvesting capabilities, presenting new opportunities for the development of cutting-edge products.

5. Despite the advancements in molding techniques, challenges still exist, including the need to balance cost, quality, and sustainability, as well as the constant pursuit of innovation to cater to evolving customer needs and to stay ahead of the competition.

< h1 >What are the SEO-Optimized Innovations in Molding Techniques for Ball Fabrication? < /h1 >

< h2 >Understanding Ball Fabrication and its Significance< /h2 >

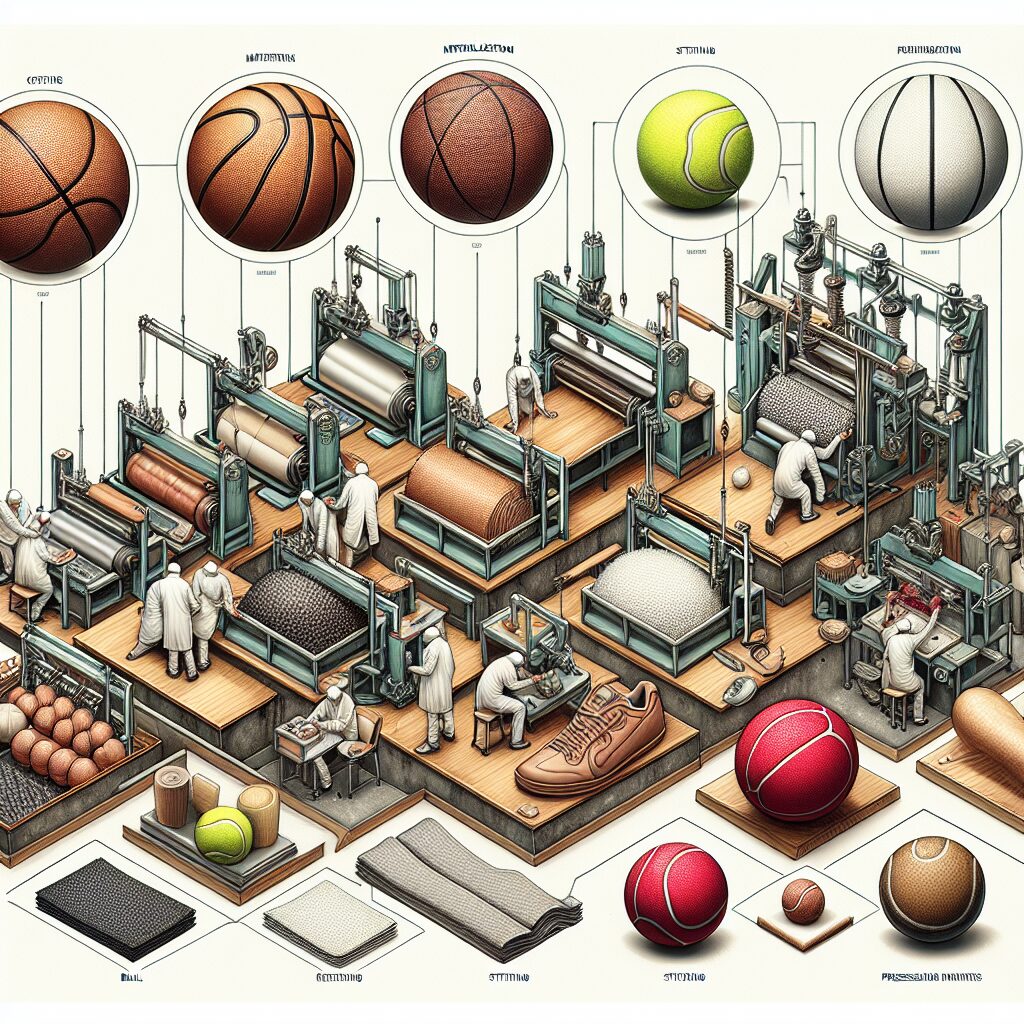

Ball fabrication refers to the process of creating spherical objects through various molding techniques. These balls find application in diverse industries, including sports, automotive, and manufacturing. With innovative molding techniques, the art of ball fabrication has witnessed a revolution, enabling manufacturers to produce high-quality and customized balls for specific purposes.

< h2 >Exploring Innovative Molding Techniques< /h2 >

Innovative molding techniques have played a crucial role in advancing ball fabrication processes. Several techniques are utilized to shape and mold balls accurately and efficiently:

< h3 >1. Injection Molding< /h3 >

Injection molding is a widely used technique for ball fabrication. It involves injecting molten material, such as plastic or rubber, into a mold cavity with a spherical shape. The material cools and solidifies, resulting in a perfectly molded ball. This technique allows for easy customization, precise dimensions, and uniformity of the final product.

< h3 >2. Compression Molding< /h3 >

Compression molding is another innovative technique used for ball fabrication. In this process, a preheated material, such as thermosetting resin or rubber, is placed in a mold cavity. The mold is then closed, and pressure is applied to compress the material and obtain the desired shape. Compression molding offers versatility in terms of material selection and allows the creation of strong and durable balls.

< h3 >3. Rotational Molding< /h3 >

Rotational molding is a unique technique used primarily for producing hollow balls. In this process, powdered material, such as plastic, is placed inside a mold. The mold is then heated and rotated along two perpendicular axes, causing the material to coat the inner surface of the mold and take its shape. Once the material solidifies, the mold is cooled, and the hollow ball is extracted. This technique offers great design flexibility and allows for the creation of complex structures.

< h2 >Benefits and Applications< /h2 >

These innovative molding techniques provide numerous benefits and have extensive applications:

< h3 >1. Enhanced Precision and Durability< /h3 >

By utilizing innovative molding techniques, manufacturers can achieve higher levels of precision and accuracy, resulting in perfectly shaped balls. The materials used and the controlled molding process ensure that the fabricated balls are durable, resistant to wear and tear, and can withstand rigorous usage.

< h3 >2. Customization and Diverse Designs< /h3 >

The advent of innovative molding techniques has allowed for extensive customization and the creation of diverse ball designs. Manufacturers can tailor the materials, colors, patterns, and textures according to specific requirements and customer preferences. This flexibility enables the production of unique balls for different applications.

< h3 >3. Wide Range of Applications< /h3 >

Innovative molding techniques have significantly expanded the range of applications for fabricated balls. From sports equipment, such as balls used in soccer, basketball, and golf, to industrial applications in valves, bearings, and automotive parts, these techniques have revolutionized ball fabrication and made it feasible for various industries to incorporate their usage.

< h2 >Conclusion< /h2 >

Innovative molding techniques have revolutionized the art of ball fabrication. Through injection molding, compression molding, and rotational molding, manufacturers can create customized, precise, and durable balls for a wide range of applications. The benefits of these techniques include enhanced precision, customization options, and expanded applications. With continuous advancements in technology, the future of ball fabrication holds even more innovative possibilities.

1. < h2 >What are the key considerations when selecting the appropriate molding technique for ball fabrication?< /h2 >

When determining the right molding technique for ball fabrication, several factors need to be considered:

– Material compatibility and properties

– Required precision and design complexity

– Production volume and efficiency requirements

– Cost-effectiveness and budget constraints

2. < h2 >How can innovative molding techniques improve the performance of sports balls?< /h2 >

Innovative molding techniques have significantly contributed to the development and enhancement of sports balls. The precise molding ensures consistency in shape and size, resulting in improved ball flight and accuracy. Additionally, customization options allow players to choose balls tailored to their specific playing styles, providing better control and performance on the field.

3. < h2 >What are the future prospects in innovative molding techniques for ball fabrication?< /h2 >

The future of innovative molding techniques in ball fabrication appears promising. Advancements in materials, such as the development of smart materials, will enable the creation of technologically advanced balls with enhanced properties. Furthermore, emerging technologies like 3D printing may revolutionize the fabrication process, offering unparalleled customization and design possibilities.

Frequently Asked Questions

1. What are innovative molding techniques?

Innovative molding techniques refer to the use of advanced and unconventional methods to create molded products. These techniques often involve the use of new materials, technologies, or processes to achieve unique and improved results.

2. How are innovative molding techniques different from traditional molding?

Innovative molding techniques differ from traditional molding methods by offering increased precision, efficiency, and versatility. These techniques allow for the creation of complex shapes, better material distribution, and improved surface finish compared to traditional molding techniques.

3. What advantages do innovative molding techniques provide?

Innovative molding techniques offer several advantages, such as enhanced design flexibility, reduced production time, improved product quality, and decreased material waste. They can also enable the production of lightweight and structurally optimized parts, leading to cost savings and performance improvements.

4. What are some commonly used innovative molding techniques?

Some commonly used innovative molding techniques include injection molding, blow molding, rotational molding, compression molding, and thermoforming. These techniques are constantly evolving with advancements in materials and technologies.

5. How can innovative molding techniques benefit the manufacturing industry?

Innovative molding techniques play a crucial role in driving advancements in the manufacturing industry. By allowing for faster production, improved product performance, and reduced costs, these techniques contribute to increased competitiveness and innovation within the industry.

6. Are there any limitations to using innovative molding techniques?

While innovative molding techniques offer numerous benefits, they may have limitations depending on the specific application. Factors such as material selection, part complexity, cost considerations, and production volumes can influence the feasibility and practicality of using certain innovative molding techniques.

7. How does the art of ball fabrication incorporate innovative molding techniques?

The art of ball fabrication utilizes innovative molding techniques to create precision-made ball products. These techniques help achieve consistent spherical shapes, precise dimensions, and uniform material distribution, resulting in high-quality ball products suitable for various applications.

8. What industries can benefit from innovative molding techniques in ball fabrication?

Innovative molding techniques in ball fabrication can benefit a wide range of industries such as automotive, aerospace, medical, sports, and consumer goods. These techniques enable the production of customized balls with specific material properties, tolerances, and performance characteristics, meeting the unique requirements of each industry.

9. How can one stay updated on the latest innovative molding techniques?

To stay updated on the latest innovative molding techniques, it is essential to follow industry publications, attend conferences, participate in workshops or webinars, and engage with professionals in the field. Additionally, keeping an eye on advancements in related technologies and materials can also provide valuable insights and information.

10. What future innovations can we expect in the field of ball fabrication using molding techniques?

The field of ball fabrication using molding techniques is constantly evolving. Future innovations may include the development of new materials with enhanced properties, advancements in molding technologies for greater efficiency, and the integration of smart features into ball products for enhanced functionality.

Final Thoughts

Innovative molding techniques have revolutionized the art of ball fabrication, offering endless possibilities for creating high-quality, precise, and customizable sphere-shaped products. These techniques bridge the gap between design creativity and production efficiency, enabling manufacturers to push boundaries and deliver innovative solutions. With ongoing advancements, the future of ball fabrication using innovative molding techniques holds promising opportunities for various industries and continues to redefine what is possible.

Embracing and harnessing the power of innovative molding techniques in ball fabrication is key to staying competitive in today’s dynamic market. By understanding the potential of these techniques and staying updated on the latest developments, manufacturers can unlock new avenues for product improvement, cost reduction, and customer satisfaction. The art of ball fabrication continues to evolve, and as techniques advance, so do the possibilities to create truly exceptional and functional ball products.