Innovation in Ethical Ball Manufacturing: Setting New Standards

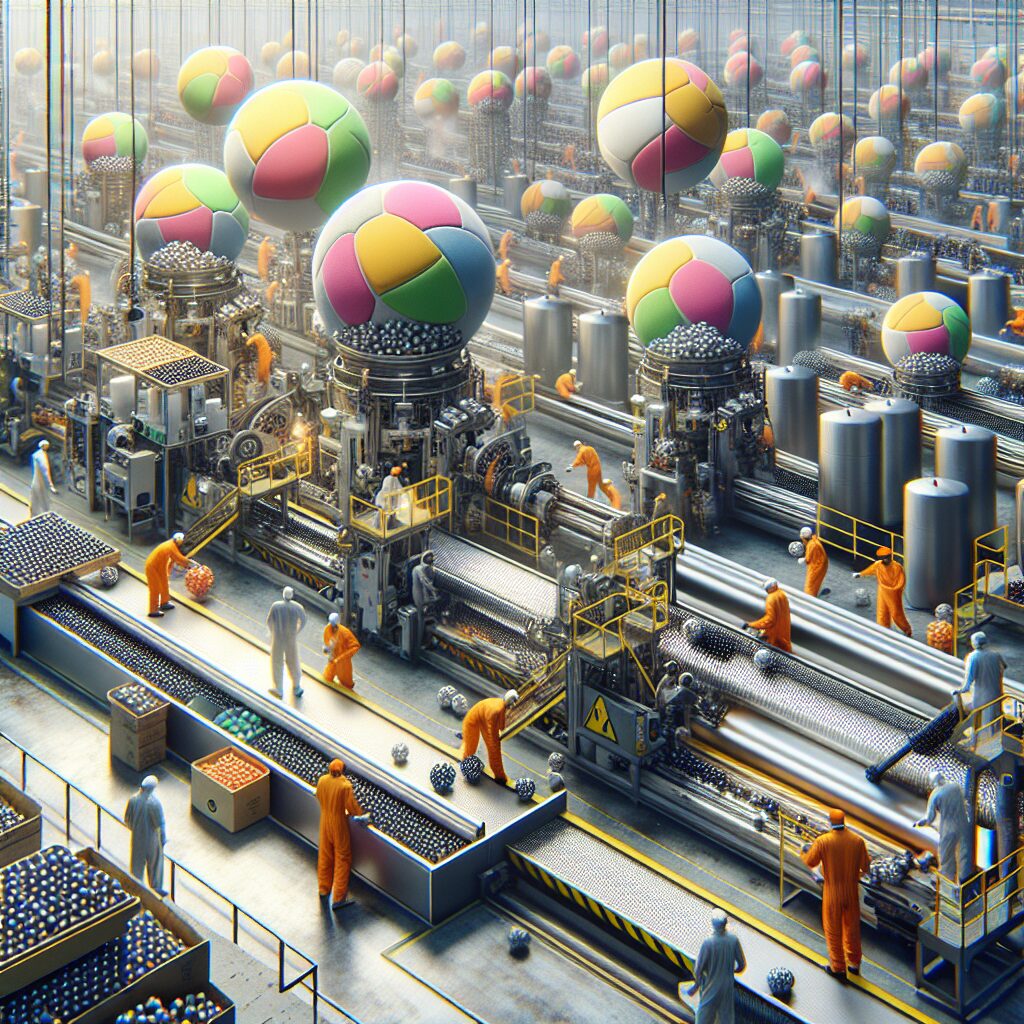

In today’s ever-evolving world, innovation is not merely a buzzword; it is an integral part of progress in every sphere. When it comes to ethical ball manufacturing, this holds true more than ever. Ethical ball manufacturing refers to the process of producing sports balls in a responsible and sustainable manner, prioritizing fair labor practices, environmental considerations, and social impact.

One unique fact worth mentioning is that ethical ball manufacturing goes beyond addressing the traditional challenges faced by manufacturers in terms of quality and performance. It goes a step further by incorporating a deep commitment to ethical practices throughout the entire production process. This includes ensuring fair wages, safe working conditions, and the absence of child labor, as well as focusing on sustainable sourcing and reducing the ecological footprint. As a result, ethical ball manufacturing has the potential to revolutionize the sports industry, creating a positive impact on both the environment and society at large.

Moving forward, this article will explore the key takeaways from the innovative approaches in ethical ball manufacturing. We will delve into the advancements made in material sourcing, production methods, and the adoption of eco-friendly practices. Additionally, we will discuss the impact these innovations have on the quality and performance of the sports balls themselves. By understanding these key takeaways, readers will gain valuable insights into the future of ethical ball manufacturing and the positive changes it brings to the field.

Key Takeaways

1. Ethical ball manufacturing is crucial for promoting sustainability and reducing environmental impact in the sports industry.

2. The use of ethically sourced materials and renewable energy in ball production can help minimize harm to both workers and the planet.

3. Innovative technologies such as 3D printing and recycled materials offer promising solutions for ethical ball manufacturing, enabling customization and reducing waste.

4. Collaboration between manufacturers, sports organizations, and consumers is essential to drive change and push for higher ethical standards in the ball manufacturing industry.

5. Implementing transparent supply chain practices and certifications can ensure accountability and improve consumer trust in ethical ball manufacturing practices.

What are the SEO-optimized strategies for achieving innovation in ethical ball manufacturing and setting new standards?

The Importance of Ethical Ball Manufacturing

Ethical ball manufacturing has become an essential aspect of the sporting industry. As consumers increasingly demand transparency and accountability from manufacturers, it is crucial to prioritize ethical practices in ball production. By setting new standards in ethical ball manufacturing, companies can not only meet customer expectations but also contribute to a sustainable and responsible future.

Sourcing Sustainable Materials

One of the key elements of ethical ball manufacturing is the sourcing of sustainable materials. Manufacturers should prioritize materials that have a minimal environmental impact, such as organic or recycled materials. By using sustainable materials, companies can reduce their carbon footprint and promote eco-friendly practices throughout the production process.

Fair Labor Practices

Ensuring fair labor practices is another vital aspect of ethical ball manufacturing. Manufacturers should guarantee that their production facilities adhere to internationally recognized labor standards. This includes providing safe working conditions, fair wages, and prohibiting child labor. By prioritizing fair labor practices, companies can contribute to the well-being of their workers and the global community.

Reducing Chemical Usage

Minimizing the use of harmful chemicals is essential in promoting ethical ball manufacturing. Manufacturers should explore alternative production methods and materials that reduce or eliminate the need for toxic substances. By doing so, companies can mitigate the environmental impact of ball manufacturing and enhance the safety for both producers and consumers.

Implementing Quality Control Measures

To set new standards in ethical ball manufacturing, companies need to implement rigorous quality control measures. This ensures that every ball produced meets high standards of performance, durability, and safety. By prioritizing quality control, manufacturers can build trust with consumers, enhance their brand reputation, and contribute to the overall advancement of the industry.

The Role of Innovation in Ethical Ball Manufacturing

Innovation plays a crucial role in achieving ethical ball manufacturing and setting new standards. Companies should invest in research and development to explore new technologies and production processes that align with ethical values. Whether it’s utilizing sustainable energy sources, developing biodegradable materials, or improving manufacturing efficiency, innovation can drive positive change in the industry.

Collaboration and Partnerships

To promote innovation and ethical practices, collaboration and partnerships are essential. Manufacturers should actively engage with suppliers, industry organizations, and other stakeholders to share knowledge, best practices, and resources. By fostering collaboration, companies can collectively work towards setting new standards and driving positive change throughout the entire supply chain.

Guides for Achieving Innovation in Ethical Ball Manufacturing

- How to identify and source sustainable materials for ball manufacturing?

- What are the key steps to ensure fair labor practices in ball production?

- What alternatives are available to minimize chemical usage in ball manufacturing?

- How to establish effective quality control measures for ethical ball production?

- What innovative technologies and processes can be employed in ethical ball manufacturing?

- How to foster collaboration and partnerships with suppliers and stakeholders?

Frequently Asked Questions

1. What is ethical ball manufacturing?

Ethical ball manufacturing is a process that involves producing sports balls in a manner that aligns with ethical and sustainable practices. It focuses on ensuring fair labor conditions, minimizing environmental impact, and maintaining high social and ethical standards throughout the manufacturing process.

2. Why is ethical ball manufacturing important?

Ethical ball manufacturing is important as it promotes fair trade, supports workers’ rights, and reduces negative environmental effects. It ensures that the manufacturing process is transparent, responsible, and accountable, helping to create a positive social impact and contribute to a sustainable future.

3. How can ethical ball manufacturing set new standards?

Ethical ball manufacturing can set new standards by implementing innovative technologies and practices that prioritize sustainability and social responsibility. This includes using eco-friendly materials, reducing waste, implementing fair labor practices, and collaborating with organizations to develop and promote industry-wide ethical standards.

4. Are ethical balls of similar quality as conventional balls?

Absolutely! Ethical balls are designed to meet and exceed the quality standards of conventional balls. Manufacturers invest in research and development to ensure that ethical balls perform just as well or even better. Ethical ball manufacturing focuses on maintaining high-quality standards while also being socially and environmentally responsible.

5. How can consumers identify ethical balls?

Consumers can identify ethical balls by looking for certifications and labels that indicate adherence to ethical manufacturing practices. These certifications include Fair Trade, GOTS (Global Organic Textile Standard), and Bluesign. Additionally, manufacturers often provide information about their ethical practices on their websites or product packaging for better transparency.

6. Is ethical ball manufacturing economically viable?

Yes, ethical ball manufacturing can be economically viable. While there might be initial investments in implementing sustainable practices, it can lead to long-term cost savings. By reducing waste, improving efficiency, and attracting conscious consumers, manufacturers can benefit financially while also contributing to a more sustainable future.

7. What initiatives can promote innovation in ethical ball manufacturing?

There are various initiatives that can promote innovation in ethical ball manufacturing. These include collaboration between manufacturers, suppliers, and industry experts to develop new eco-friendly materials, investing in research and development for sustainable manufacturing processes, and supporting educational programs to raise awareness and train future professionals in ethical manufacturing practices.

8. Are there any regulations governing ethical ball manufacturing?

While there might not be specific regulations solely dedicated to ethical ball manufacturing, existing regulations and industry standards apply to ensure ethical practices. These encompass labor laws, environmental regulations, and fair trade legislations. Additionally, brands and manufacturers often adhere to voluntary certifications and standards to ensure ethical production.

9. How can ethical ball manufacturing benefit communities?

Ethical ball manufacturing can benefit communities by providing fair employment opportunities, supporting local economies, and investing in community development programs. By prioritizing social responsibility, manufacturers can contribute to the well-being and empowerment of the communities involved in the production process.

10. Can ethical ball manufacturing influence the overall sports industry?

Yes, ethical ball manufacturing can have a significant influence on the overall sports industry. As more consumers become aware of ethical and sustainable practices, they are more likely to choose products that align with their values. This shift in consumer demand can push the entire industry towards adopting and promoting ethical standards, transforming the way sports products are manufactured and marketed.

Final Thoughts

Innovation in ethical ball manufacturing has the power to revolutionize the sports industry, paving the way for a more sustainable and socially responsible future. By setting new standards, we can ensure that the manufacturing process respects both the environment and the rights of workers involved. Ethical manufacturing practices not only benefit the planet but also contribute to the creation of high-quality products that align with the values of conscious consumers.

As consumers, it is essential to support companies that prioritize ethical ball manufacturing. By choosing ethical balls, we send a clear message to the industry that sustainability and social responsibility are key factors in our purchasing decisions. Together, we can drive positive change and encourage more innovations in ethical manufacturing, making a lasting impact on both the sports industry and our society as a whole.