Removing an upper ball joint can be a complicated process that requires special tools and a great deal of patience. It is important to understand the process before attempting it, as improper removal of the ball joint can cause damage to the vehicle. This guide will provide instructions on how to properly remove an upper ball joint from a vehicle, including what tools you will need and the steps involved.To remove the upper ball joints on a car, you will need a few tools. First, you will need an air or electric impact wrench to loosen the nuts that hold the ball joint in place. Then, use a pry bar or large screwdriver to separate the ball joint from its mounting. Finally, use a hammer or press to drive out the upper control arm shaft. Be sure to support the lower control arm while doing this so it does not become damaged.

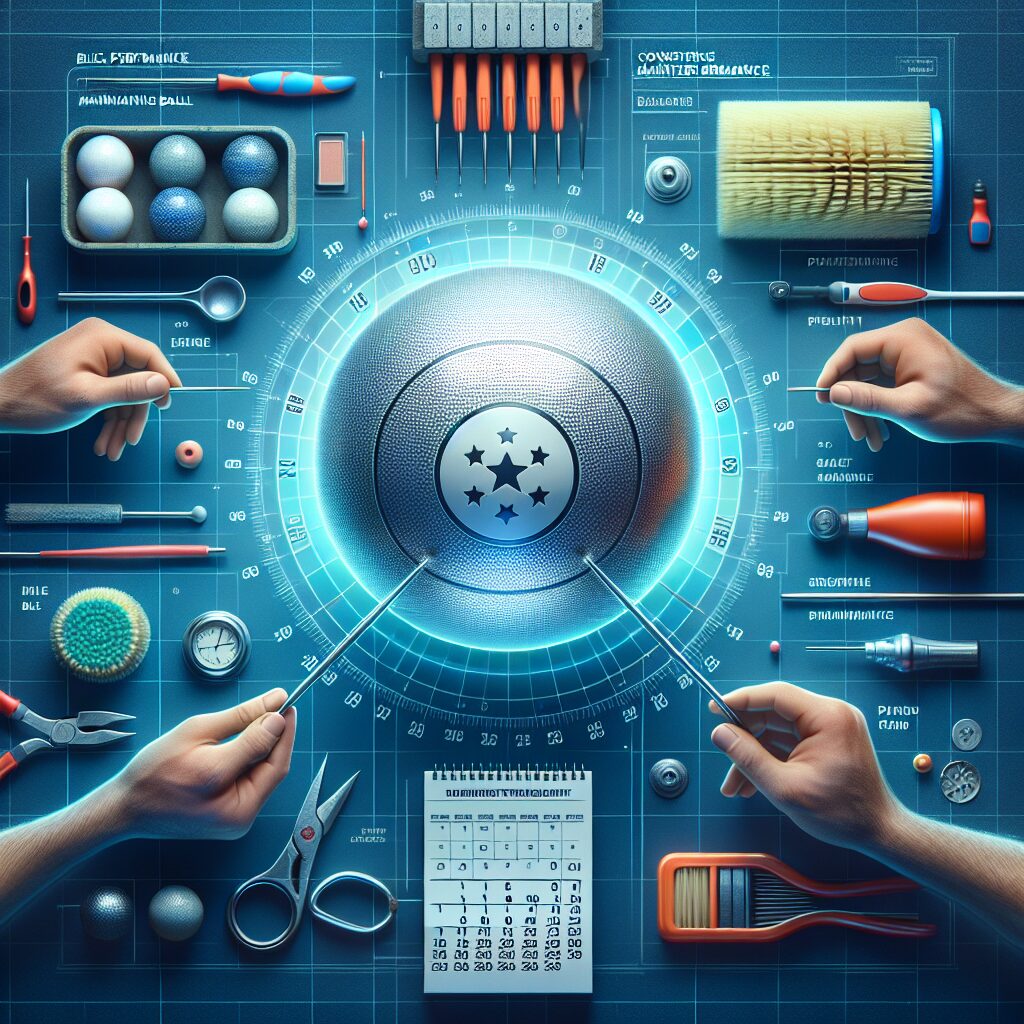

Gather the Necessary Tools and Parts

Before you start any DIY project, it is essential to have all the necessary tools and parts that you need. Having the right tools and parts will help ensure that your project goes smoothly and that you get the best results. Make sure to check whether there are any special tools required for your particular job. It is important to make sure that you have all of the necessary tools and parts before starting on a project. This will help save time and money in the long run.

Also, make sure to check what kind of safety equipment is needed for a particular job. Safety should always come first when doing any DIY project. Wear protective clothing such as gloves, eye protection, and a dust mask if necessary. Having these items on hand will ensure your safety during your project.

Once you have gathered all of your tools and parts, organize them in an easy-to-see manner so that you can find them quickly when needed during the project. This will save time in the long run by avoiding frustration from searching for misplaced items during a crucial moment of your project.

Precautionary Measures for Removing Upper Ball Joints

It is important to take the necessary precautions when removing the upper ball joints in order to avoid any damage. Before beginning, make sure that the vehicle is securely lifted and supported on jack stands. Once the vehicle is off the ground, all wheel nuts should be removed and the wheels taken off. It is also important to have a breaker bar and socket set ready before starting to remove the ball joint. The breaker bar should be placed on the top of the nut and used to break it loose before removing it completely with a socket wrench. Once the nut is removed, proceed to disconnect the upper ball joint from its mount using a pickle fork. After that, use a pry bar or a hammer handle to force out any remaining pieces of the ball joint until it comes out of its mount entirely.

If you are having difficulty with removing old or rusted nuts and bolts, it is best to apply some penetrating oil before attempting to loosen them. Additionally, it is important to inspect all components thoroughly for any wear or damage prior to installation of new parts. It is also recommended that you replace all mounting bolts when replacing upper ball joints as well as torque them properly in order for them to work correctly. Taking these precautionary measures will ensure that your upper ball joints are removed safely and correctly without any unnecessary damage occurring during removal.

Step 1: Prepare the Vehicle

The first step in removing upper ball joints is to prepare the vehicle. This involves raising the vehicle off the ground and placing it on jack stands. Make sure that the vehicle is securely supported and ready for work before beginning. Additionally, wear safety equipment, such as gloves and goggles, to protect yourself from any potential debris.

Step 2: Remove the Wheel

Once you have prepared the vehicle for work, you will need to remove the wheel in order to gain access to the upper ball joint. To do this, use a wrench or ratchet to loosen and remove any lug nuts that are holding the wheel in place. Once all of the lug nuts have been removed, carefully lift off the wheel and set aside.

Step 3: Detach Suspension Arm

The next step is to detach the suspension arm from the steering knuckle. This can be done by using a wrench or socket wrench to loosen and remove any bolts that are holding them together. Once all of these bolts have been removed, you will be able to carefully pull apart both pieces.

Step 4: Remove Upper Ball Joint

Now that you have access to it, you can begin removing the upper ball joint. To do this, use a ball joint separator tool or pickle fork to pry apart both pieces of hardware. As you pry them apart, make sure that you are applying even pressure so that neither piece is damaged in any way. Once both pieces are separated, carefully remove them from their respective positions.

Step 5: Clean Up

Finally, once all of your work has been done, clean up your tools and workspace so that it is ready for reassembly when necessary. When cleaning up debris from around your vehicle, make sure not to miss any small pieces of hardware or other materials that may have become dislodged during your work. The top ball joint nut can be located on the suspension arm of your vehicle. It is a metal nut that is usually found in the center of the suspension arm. It is typically held in place by two bolts and can be accessed by removing these bolts. Once removed, the nut should be visible from underneath the vehicle. If you cannot locate it, you may need to jack up the vehicle and check from above. Once located, it should be easy to remove with a socket wrench or other suitable tool. It is important to make sure that the top ball joint nut is securely tightened before driving your vehicle. If it is not securely tightened, it could lead to damage to your suspension system or worse, an accident. It is also important to regularly inspect this part for any signs of wear or damage as this could lead to an increased risk of failure while driving. When performing work on your suspension, it is important to unfasten the upper ball joint nut. This nut can be found at the top of the upper ball joint on your vehicle’s suspension system. It is important to use a socket and ratchet set to remove this nut, as it can be difficult to reach otherwise. Make sure you have a good grip on the socket and ratchet to ensure that it remains secure while you are removing the nut. Once you have removed the nut, you can inspect the ball joint for any signs of wear or damage. If there is any visible damage, it should be repaired or replaced before continuing with any further work on your suspension system. It is also important to ensure that all of the components in your suspension system are properly lubricated before re-installing the upper ball joint nut. Using a quality lubricant will help reduce friction and ensure that all of the parts move freely without any issues. Once you have applied lubricant to all of the necessary parts, you can begin re-installing the nut by threading it onto its corresponding bolt and tightening it using a socket and ratchet set. Make sure to double check that everything is secure before driving your vehicle again. Separating the components of a hammer and punch or pickle fork is a necessary step when repairing or replacing parts of the tool. The hammer head is typically connected to the handle through a series of pins, which must be removed before any other repairs can be done. To properly separate the two components, you will need a hammer, punch, or pickle fork. First, position the head of the hammer on a solid surface. Make sure that it is level and stable before beginning to work. Once it is secure, place the punch or pickle fork at the base of each pin. Strike the head of the tool with a hammer until each pin is driven out of its hole in the handle. Once all pins have been removed, carefully separate the head from the handle. The two components should easily come apart with little effort. If any pins remain in either component after they have been separated, use tweezers or needle-nose pliers to remove them. Once you have successfully separated the components, inspect both pieces for any defects that may have occurred during removal. Replace any damaged parts as necessary before reassembling them again and putting them back into service. With proper care and maintenance, your hammer and punch or pickle fork should last for years to come! It is important to inspect the condition of the old ball joints before installing new ones. This is a necessary step to ensure that no damage has occurred and that there are no signs of wear or tear. Ball joints are a critical part of the suspension system, so it is important to take the time to inspect them thoroughly before replacing them. To begin inspection, remove any dust or dirt from around the ball joint and check for any signs of corrosion or rust. Make sure there are no cracks, splits, or wear marks on the ball joint itself. Check for any loose pieces in the housing, as well as any broken parts. If there is any visible damage, it may be necessary to replace the ball joint entirely. Next, check for any signs of fluid leakage around the joint itself. Look for discoloration or wet spots on the surrounding area that could indicate a leak. If you find any fluid leakage, it may be necessary to replace the entire ball joint assembly rather than just one portion of it. Finally, check for excessive play in the ball joint itself by pushing and pulling on it gently. If there is too much play in the joint when pushed and pulled, then it may be too worn out and need replacing immediately. Any excessive play can cause problems with steering and handling if left unchecked. Inspecting old ball joints before installing new ones is an important step in ensuring that your vehicle’s suspension system will remain safe and functional for years to come. Taking time to properly inspect each component can save you money in costly repairs down the road and help you avoid dangerous situations while driving. Removing an upper ball joint is no easy feat, but with the right tools and a bit of know-how, it can be done. Start by disconnecting the steering linkage and axle shaft. Then, use a ball joint press tool to press out the old ball joint and press in the new one. Finally, reattach the steering linkage and axle shaft before reinstalling the wheel. Make sure to torque all bolts to manufacturer specifications for safety. It is important to remember that ball joints are a critical component of your vehicle’s suspension system. If you notice any issues with your suspension such as clunking noises or vibrations, it is important to inspect your ball joints for wear or damage and replace them as necessary. With proper maintenance and care, you can ensure that your suspension system will remain in good working condition for many years to come.

Unfasten the Upper Ball Joint Nut

Using a Hammer and Punch or Pickle Fork to Separate the Components

Inspect the Condition of the Old Ball Joints

Conclusion