A bowling ball is an essential piece of equipment for the sport of bowling. The construction of a bowling ball involves a complex process that requires specialized materials and expert craftsmanship. From the selection of the raw materials to the finished product, each step in the manufacturing process has an important role in creating a ball with optimized performance and durability. In this article, we will take a look at how bowling balls are made, from start to finish.Bowling ball making is the process of producing a bowling ball from its raw materials. The first step involves selecting the type of material for the ball, which can include polyester, urethane, or reactive resin. The material is then cut into pieces and heated to form a mold that will shape the bowling ball. Next, the core is inserted into the mold and held in place with a rubber band. The core can be made of plastic or rubber and is used to increase or decrease weight, adjust balance, or control spin. Next, the coverstock must be added to the outer part of the mold and heated until it takes shape around the core. Once cooled and removed from the mold, holes are drilled into it to allow air to escape when rolled down a lane. Finally, graphics may be added to give each ball its unique look before its ready for use on a bowling alley!

Raw Materials Needed

When making a product, it is important to know what raw materials are needed. Raw materials are the source materials that are used to create a product or service. They can include anything from metals, plastics, and wood to chemicals, minerals, and fabrics. Depending on the product being created, a variety of different raw materials may be needed. For example, if a company is manufacturing cars, it will need plastic, metal, rubber, and glass. If a company is making clothes, it will need fabrics such as cotton or polyester. In order to determine what raw materials are necessary for a particular product or service, it is important to understand the process of creating the item and what components go into it.

Once the necessary raw materials have been identified and gathered, they must be processed in order to make them suitable for use in the manufacturing process. This may involve cutting or shaping them into specific sizes and shapes as well as treating them with certain chemicals or heat processes. The processed raw materials must then be tested in order to ensure that they meet all quality standards before being used in production.

Finally, it is important to consider how much of each raw material will be needed for production. This can be determined by calculating the total amount of material required for each step in the manufacturing process and adding up all of these figures together. Having an accurate estimate of how much material is needed is essential in ensuring that production runs smoothly without delays due to shortages of raw material.

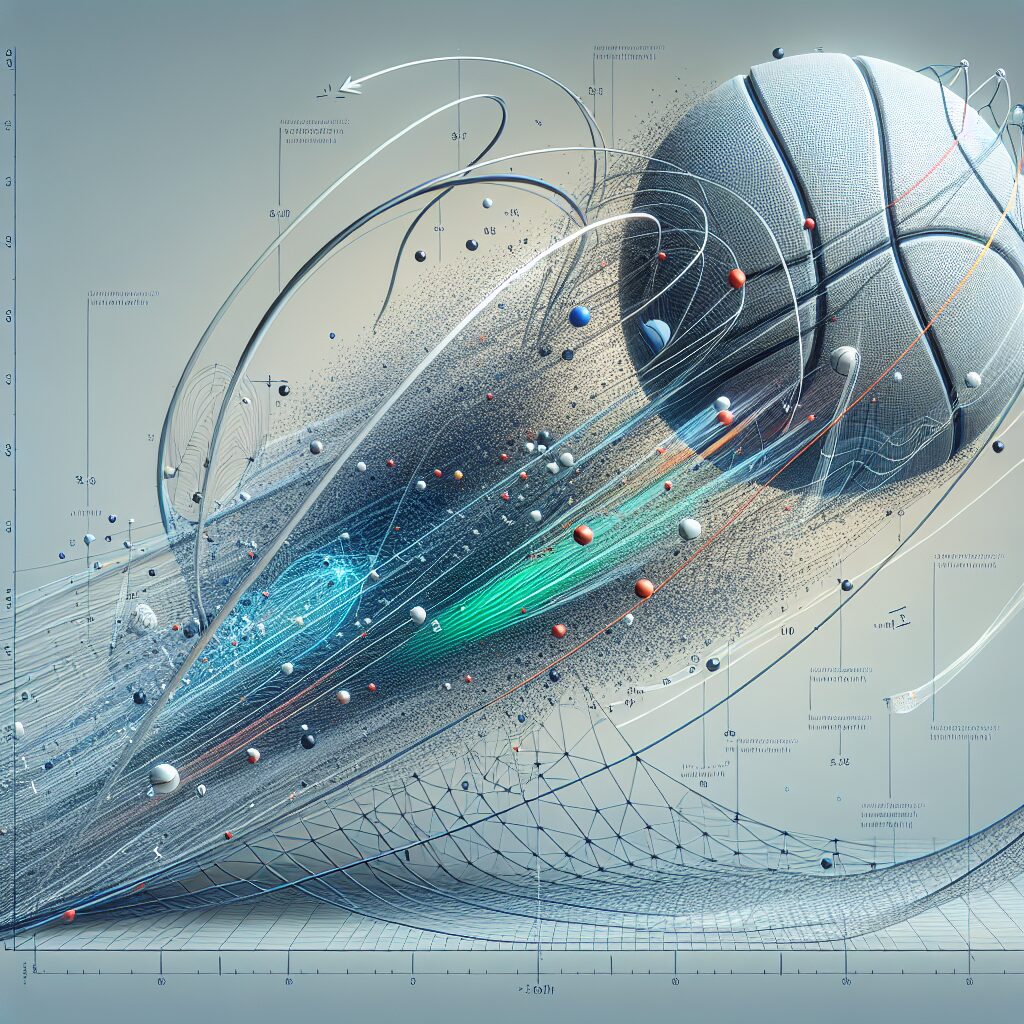

Designing the Bowling Ball

Designing the perfect bowling ball is a complex process that requires careful consideration of a variety of factors. It’s important to understand the physics behind how a bowling ball moves and how it interacts with the pins and lane surface. The material used for the ball, its size, weight, surface texture and core all play an important role in determining how the ball will react when thrown down the lane.

The material used to make a bowling ball is incredibly important. Polyester is most common, as it has good durability and can provide good durability and a consistent reaction on the lane. Urethane is also used due to its hardness and ability to grip better than polyester. There are also reactive resin balls that provide more hook potential than either polyester or urethane balls.

The size and weight of a bowling ball are also important considerations when designing your own perfect ball. The standard size for an adult male bowler is 8 1/2 inches in circumference with a weight of 16 pounds or less. You can find balls available in weights from six pounds up to 16 pounds, with varying sizes available for younger bowlers as well as senior bowlers.

The surface texture of your bowling ball will have an impact on its performance down the lane. A smooth finish will cause less friction between the ball and lane, resulting in more skid before it reaches the pins. A more textured finish will cause more friction between the ball and lane, creating hook potential which can be useful for certain types of lanes or bowlers who want to curve their shots around obstacles or other pins.

Finally, there’s the core of your bowling ball which affects its overall performance as well as its reaction on different types of conditions on different lanes from house to house. Cores vary in shape from symmetrical cores which provide more control while asymmetrical cores offer more hook potential depending on their design. Different core designs can be combined with different coverstocks to create custom reactions depending on what type of shot you want to throw or what type of condition you need to match on any given day at any given house.

Ultimately, designing your own perfect bowling ball requires careful consideration of all these factors so that you can get exactly what you need out of it each time you step onto the lanes!

Molding the Bowling Ball

Molding a bowling ball is an important process that can have a significant impact on the performance of the ball. The process involves heating the urethane material and injecting it into a mold. The mold is then cooled so that the material solidifies and takes on the shape of the mold. Once cooled, the ball is removed from the mold and any excess material is trimmed away. After that, drilling holes in the ball for fingers and thumb are done to create a custom fit for each bowler. The drilling also helps to customize the bowling ball’s performance by allowing different types of weights and layouts to be used. Finally, graphics and logos are applied to give the bowling ball a customized look.

Molding bowling balls requires careful attention to detail, as any imperfections can affect its performance. Therefore, it is important to take your time when heating and cooling the urethane material in order to ensure that all parts of the ball are properly formed. Additionally, it is important to make sure that any excess material is trimmed away cleanly so that it does not affect performance or aesthetics. Finally, it is important to ensure that all holes are drilled with precision in order to achieve a proper fit for each bowler’s hand size and desired performance characteristics.

Drilling the Fingers and Thumb Holes

Drilling the fingers and thumb holes is one of the most important steps when making a wooden bowl. This is because it helps to prevent the bowl from splitting or cracking during use. It also helps to make sure that the bowl is comfortable to hold in your hands. The first step in drilling these holes is to mark the locations of the holes on the bowl using a pencil. Make sure to measure carefully before marking so that all of the holes will be properly aligned.

Once you have marked the locations of all of the holes, you will need to use a drill bit that is slightly larger than the diameter of your finger or thumb. This will allow for some wiggle room when inserting your fingers into the bowl. When drilling, it is important to go slowly and apply light pressure so that you do not damage or split the wood.

Once all of your holes have been drilled, you can then sand them down using an electric sander or sandpaper. This will help to smooth out any rough edges and ensure that your fingers and thumbs fit comfortably into each hole. Finally, finish off by applying a few coats of wood sealer or varnish to protect your bowl from wear and tear over time. With these steps, you can easily create a beautiful wooden bowl with perfectly drilled finger and thumb holes!

Inserting the Weight Block

Weight blocks are a great way to add weight to your workouts and increase resistance. They are designed to be inserted into barbells or dumbbells, allowing you to increase the amount of weight on each lift. To insert a weight block, first make sure the barbell or dumbbell is secured in a stand or rack. Place the weight block onto the bar and then slide it down until it sits firmly against the bar. Make sure to double check that all sides of the weight block are properly secured. Once you’re sure everything is secure, you’re ready to begin your workout.

Weight blocks can also be used in conjunction with other pieces of gym equipment, such as cable machines and exercise balls. Simply attach the weight block to the desired unit and then use it as you would any other piece of equipment. Be sure to adjust the amount of resistance according to your own strength and fitness level. With a little practice, you’ll soon be able to take full advantage of all that adding weights has to offer.

Design and Layout

When it comes to designing and laying out a space, it’s important to consider how the elements you choose will interact with each other. You need to think about what colors will be used, as well as what kind of furniture and accessories will be included in the room. It’s also important to consider the natural lighting in the area and how it will affect the overall look of the space. Once you have a plan in place, you can begin to bring your design ideas to life.

Accessorizing

Accessorizing your space is all about adding personal touches that reflect your unique style. This could include items like artwork, throw pillows, plants, rugs, wall hangings, or anything else that brings life to your space. It’s important to choose items that are both functional and aesthetically pleasing so that they can enhance the overall look of the room.

Lighting

Lighting plays an important role in any room as it can create different moods and atmospheres depending on its placement and intensity. Natural lighting from windows can add warmth to a space while lamps can be used for task lighting or for creating a cozy atmosphere. It’s important to consider how much lighting you need when designing a room and which type of light fixtures would work best in order to achieve your desired effect.

Finishing Touches

Once all of your design elements are in place, it’s time for those final touches that can really make a space shine. This could include adding accent pieces such as candles or vases; hanging curtains or blinds; or even adding some greenery with plants or flowers. These small additions can make all the difference in creating a warm and inviting atmosphere that is uniquely yours.

Compression Testing the Ball

Compression testing is an important part of ensuring that a golf ball meets the standards for performance and durability. This test measures the force required to compress a golf ball from its normal size to a smaller size. The amount of force required is measured using a machine that applies a specific amount of pressure to the golf ball and records the results. The results are then compared to industry standards and accepted ranges of acceptable compression values. If the compression values are outside of these ranges, then the golf ball is not approved for use in tournament play or general recreational play.

The test is conducted in two stages: First, a pressure plate is placed on top of a golf ball to measure its initial size and weight. Then, an additional force is applied to compress the golf ball until it reaches its final compressed size. The amount of pressure used during this process will vary depending on the type and quality of the golf ball being tested. Once this process has been completed, the compression value is calculated by subtracting the initial weight and size from the final weight and size measurements.

Compression testing can be used to evaluate how well a particular type or brand of golf ball performs on different surfaces and conditions. It can also help determine which types of balls are best suited for certain types of players or playing conditions such as long drives or short shots around obstacles. By comparing different brands and types against each other, you can identify which balls provide optimal performance for your game.

In addition to helping you make better purchasing decisions when it comes to buying new golf balls, compression testing can also be used to identify any potential problems with existing balls that may need further examination or repair. If you suspect that your current balls are not performing as they should, it’s worth having them compression tested so that any issues can be identified and rectified before they become worse down the line.

Overall, compression testing plays an essential role in ensuring that all golf balls meet industry standards for performance and durability. It’s important for players to understand how this test works so that they can make informed decisions when buying new equipment or making repairs on existing equipment.

Conclusion

The process of making a bowling ball is a complex and lengthy one, but it is also one that yields high-quality results. From the selection of the materials to the drilling of the finger holes, every step requires skill and precision. Only with the help of experienced professionals can a bowling ball be made that meets the highest standards of quality.

The combination of advanced technology and craftsmanship makes it possible for manufacturers to produce durable balls that provide bowlers with smooth, consistent performance on every roll. The final product is a testament to the skill and dedication of those who crafted it.

Ultimately, making a bowling ball involves an intricate series of steps that come together to create something truly special. It’s no wonder that so many people appreciate and enjoy this beloved sport.