Green manufacturing in the context of ball production refers to the implementation of sustainable and environmentally-friendly practices throughout the entire manufacturing process. This means minimizing waste, conserving energy, and reducing the carbon footprint associated with producing balls for various sports and recreational activities. As the demand for eco-friendly products continues to rise, the sports industry has also recognized the need to align with sustainable practices. Green manufacturing in ball production has significant impacts not only on the environment but also on the quality and performance of the final product. By incorporating sustainable materials and innovative production techniques, manufacturers are able to create balls that are not only durable and high-performing but also have a minimal impact on our planet.

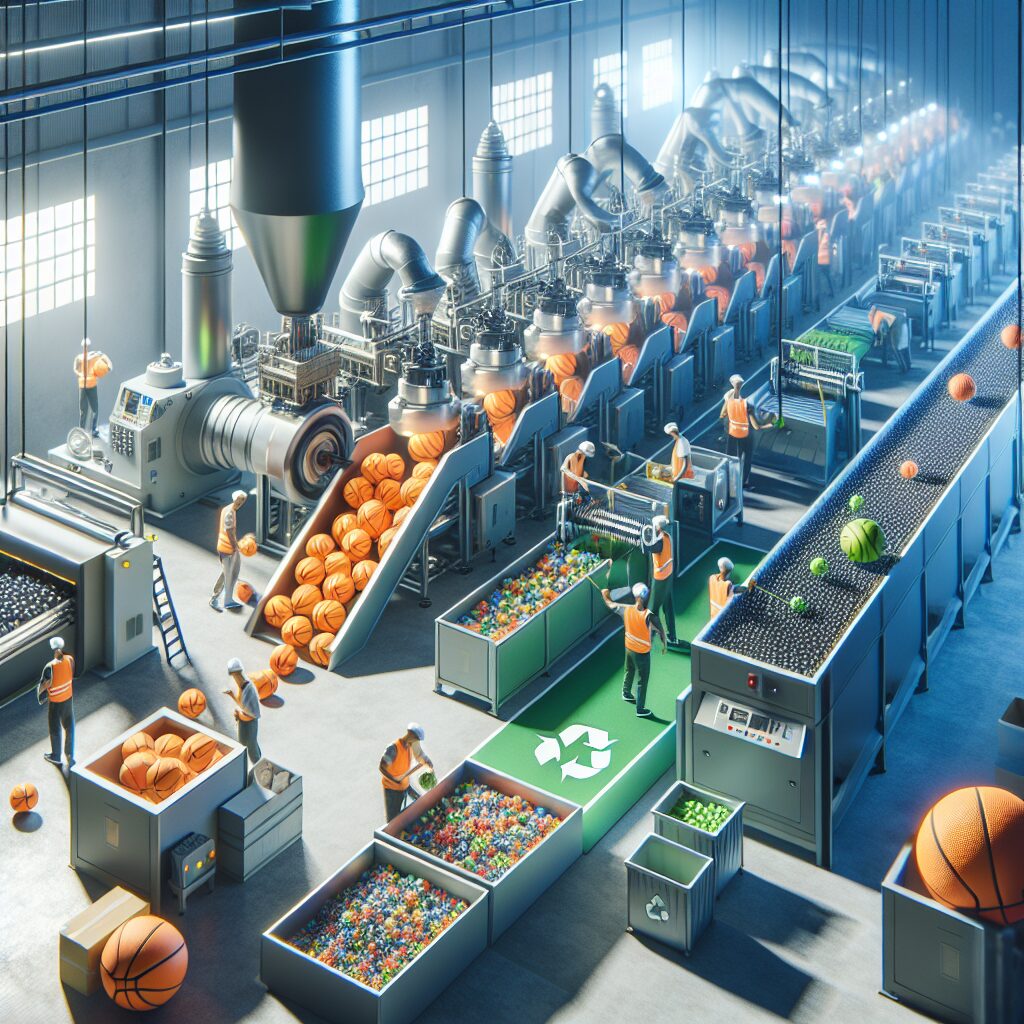

One key aspect of green manufacturing in ball production is the use of recycled materials. By utilizing recycled plastics, rubbers, and fibers, manufacturers are able to reduce the dependency on virgin materials, thereby minimizing waste and conserving natural resources. Additionally, the incorporation of sustainable materials does not compromise the quality or performance of the balls. In fact, advancements in technology have enabled manufacturers to develop balls that meet the same standards and specifications as those made from traditional materials. This not only benefits the environment but also provides athletes and sports enthusiasts with high-quality products that perform just as well, if not better.

Moving forward, we will explore the key takeaways of green manufacturing in ball production. We will discuss the importance of sustainable materials and their impact on the environment and product performance. Additionally, we will delve into the innovative production techniques and technologies that allow manufacturers to create eco-friendly balls without compromising on quality. Lastly, we will examine the consumer demand for sustainable products and how green manufacturing in ball production can address this growing need. Stay tuned to discover the exciting possibilities and transformative impact of green manufacturing in shaping the future of ball production.

Key Takeaways

1. Green manufacturing initiatives are transforming ball production processes to reduce environmental impact and improve sustainability through the use of eco-friendly materials and energy-efficient technologies.

2. The shift towards green manufacturing in ball production includes the adoption of recycled materials, such as rubber from discarded tires, to minimize waste and reduce reliance on virgin materials.

3. Implementing renewable energy sources, such as solar power, and optimizing manufacturing equipment and processes help reduce greenhouse gas emissions and overall energy consumption in ball production.

4. Green manufacturing practices also prioritize the health and safety of workers by focusing on improved ventilation systems, reduced chemical usage, and ergonomic designs for equipment, enhancing the overall work environment.

5. As customers increasingly demand sustainable products, adopting green manufacturing practices not only meets market expectations but also presents opportunities for companies to differentiate themselves and enhance their brand image.

What are the Benefits of Green Manufacturing in Transforming Ball Production?

The Importance of Green Manufacturing

Green manufacturing is a revolutionary approach to industrial production that focuses on sustainability and eco-friendliness. In the context of ball production, implementing green manufacturing practices can bring about several significant benefits. By reducing environmental impact, optimizing resource utilization, and minimizing waste, green manufacturing plays a crucial role in transforming the ball production industry.

Efficiency and Cost Savings

One of the primary advantages of green manufacturing in ball production is increased efficiency and cost savings. By embracing sustainable practices, manufacturers can optimize their energy consumption and reduce material waste. This leads to streamlined production processes and lower operational costs. Moreover, energy-efficient technologies and renewable energy sources further contribute to cost savings in the long run.

Eco-Friendly Materials

Green manufacturing also involves utilizing eco-friendly materials in ball production. Traditional production methods often rely on harmful chemicals and non-sustainable resources. However, by adopting green manufacturing practices, manufacturers can shift towards the usage of environmentally friendly materials such as recycled plastic or organic compounds. This not only reduces the carbon footprint but also results in safer and healthier products.

Reduced Emissions and Pollution

Another critical aspect of green manufacturing in ball production is the reduction of emissions and pollution. Traditional manufacturing processes release harmful pollutants and contribute to air and water pollution. Green manufacturing techniques, such as implementing advanced filtration systems, energy-efficient machinery, and sustainable waste management practices, significantly decrease these emissions. As a result, the production of balls becomes environmentally friendly and supports overall sustainability goals.

Enhancing Corporate Social Responsibility

In today’s society, corporate social responsibility has become increasingly important. Companies that prioritize their environmental impact and sustainability practices gain a competitive advantage and build a positive reputation among consumers. By implementing green manufacturing in ball production, companies are aligning themselves with these values and showcasing their commitment to the environment. This enhances brand image and attracts environmentally conscious customers and partners.

Ensuring Long-Term Sustainability

Green manufacturing in ball production is not just a short-term solution, but a long-term strategy to ensure sustainability. By implementing sustainable practices and constantly seeking innovative ways to reduce environmental impact, manufacturers can create a sustainable future for the industry. This proactive approach helps in tackling the pressing issues of climate change, resource depletion, and environmental degradation.

- Minimize waste generation: Are there methods to reduce waste during ball production?

- Implement renewable energy sources: What are the benefits of utilizing renewable energy in the production process?

- Promote product recycling: How can manufacturers encourage customers to recycle used balls?

- Optimize transportation methods: Which transportation techniques help in reducing emissions during ball distribution?

- Invest in research and development: How can continuous research and development drive the innovation of eco-friendly ball production methods?

10 Frequently Asked Questions

1. What is Green Manufacturing?

Green Manufacturing refers to the process of producing goods using environmentally friendly and sustainable practices. It focuses on minimizing waste, reducing energy consumption, and using eco-friendly materials.

2. Why is Green Manufacturing important for ball production?

Green Manufacturing in ball production is important because it helps reduce the environmental impact caused by the manufacturing process. It aims to minimize greenhouse gas emissions, conserve natural resources, and promote a healthier and sustainable future.

3. How can Green Manufacturing benefit the environment?

Green Manufacturing benefits the environment by reducing pollution, conserving water and energy, minimizing waste generation, and promoting the use of renewable materials. It helps in preserving natural resources and mitigating the negative effects of manufacturing on the planet.

4. Are Green Manufacturing practices cost-effective?

Yes, Green Manufacturing practices can be cost-effective in the long run. While there may initially be some investment in eco-friendly technologies and processes, the savings achieved through reduced resource consumption, waste management, and energy efficiency can lead to significant cost savings.

5. Can Green Manufacturing improve the quality of ball products?

Yes, Green Manufacturing can improve the quality of ball products. By implementing sustainable processes, manufacturers can enhance product durability, reduce defects, and ensure better overall performance. This can contribute to customer satisfaction and increased product longevity.

6. What are some examples of Green Manufacturing practices in ball production?

Examples of Green Manufacturing practices in ball production include using recycled materials, implementing energy-efficient machinery, optimizing production processes to minimize waste, adopting water conservation measures, and controlling emissions through advanced filtration systems.

7. How does Green Manufacturing promote sustainability?

Green Manufacturing promotes sustainability by minimizing the use of non-renewable resources, reducing waste generation, decreasing carbon emissions, and adopting eco-friendly practices. It aims to meet the needs of the present without compromising the ability of future generations to meet their own needs.

8. What certifications or standards are relevant to Green Manufacturing in ball production?

Certifications and standards relevant to Green Manufacturing in ball production include ISO 14001 (Environmental Management Systems), LEED (Leadership in Energy and Environmental Design), and Eco-Label certifications such as the Blue Angel or Green Seal.

9. How can consumers support Green Manufacturing?

Consumers can support Green Manufacturing by choosing products from manufacturers committed to sustainable and eco-friendly practices. They can also promote recycling, energy conservation, and the use of eco-friendly materials by making conscious purchasing decisions and advocating for greener choices.

10. Are there any challenges in implementing Green Manufacturing in ball production?

Implementing Green Manufacturing in ball production can come with challenges such as the initial investment required for new equipment and technologies, resistance to change from stakeholders, and finding viable alternatives for certain materials or processes. However, these challenges can be overcome through proactive planning and collaboration.

Final Thoughts on Green Manufacturing: Transforming Ball Production

Green Manufacturing in ball production holds immense potential to revolutionize the industry by creating a more sustainable, eco-friendly, and socially responsible manufacturing process. By adopting environmentally conscious practices, manufacturers not only contribute to a healthier planet but also gain a competitive edge in the market.

With consumers becoming increasingly aware of the environmental impact of their purchases, the demand for sustainable products continues to rise. Implementing Green Manufacturing techniques not only reduces the ecological footprint of ball production but also aligns businesses with the values and expectations of the conscious consumer. Embracing Green Manufacturing is a win-win situation that benefits both the environment and the ball production industry as a whole.