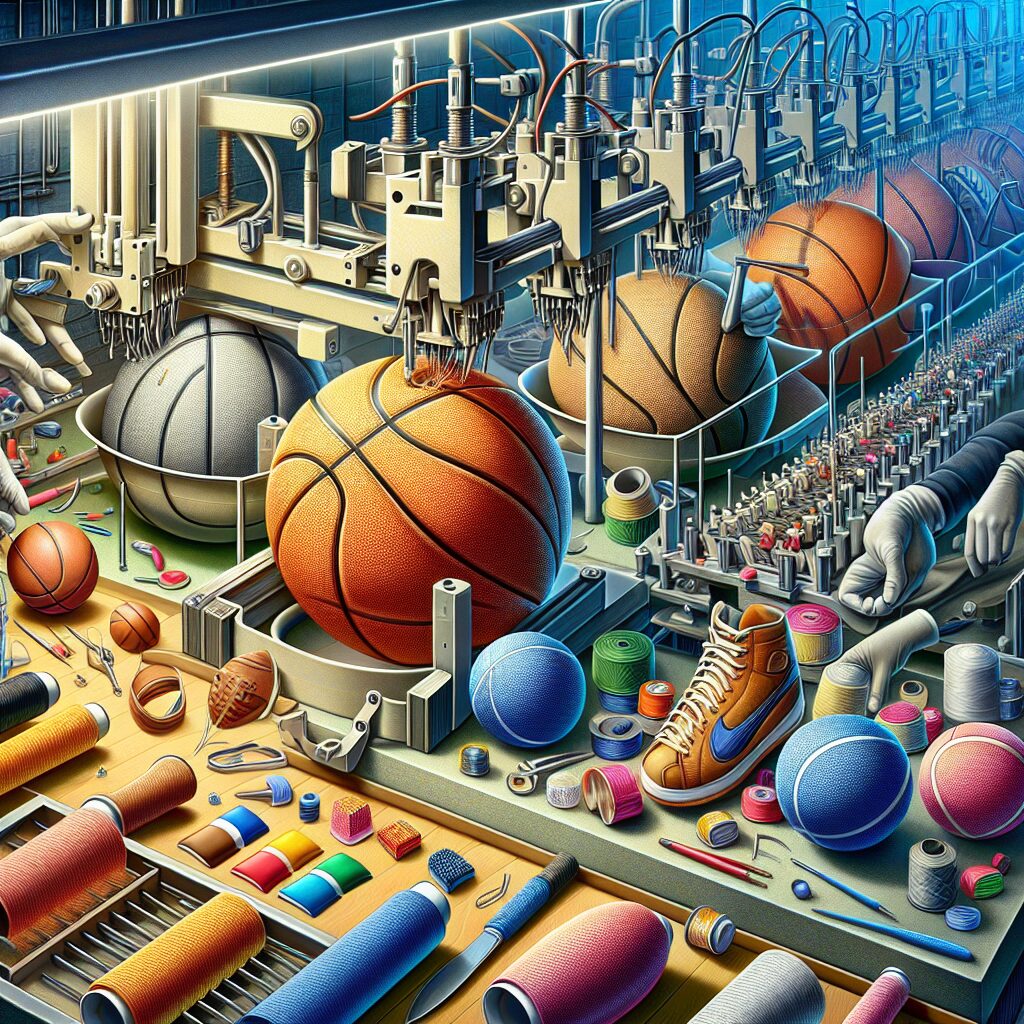

Exploring Ball Production Methods is a fascinating topic that delves into the intricate process of creating various types of balls used in sports, games, and recreational activities. From the humble beginnings of primitive balls made from animal bladders to the modern-day precision manufacturing techniques, ball production methods have evolved significantly over time. Understanding the different techniques employed in creating balls not only sheds light on the rich history of these objects but also highlights the innovation and technology involved in their production.

One of the unique aspects of ball production methods is the extensive range of impacts they have on the final product. For instance, the material used in the construction of a ball greatly affects its durability, bounce, and overall performance. Whether it’s leather, rubber, synthetic materials, or a combination of these, each material possesses distinct characteristics that make it suitable for certain sports or games. Additionally, the manufacturing process, including stitching, molding, or inflating the ball, plays a crucial role in determining its shape, consistency, and responsiveness. The combination of materials, manufacturing technique, and design choices creates a diverse array of balls tailored for specific purposes.

In the forthcoming sections, we will delve deeper into the key takeaways of exploring ball production methods. We will examine the various materials used in ball production and their impact on performance, discuss the different manufacturing techniques employed, and explore the importance of design considerations. By the end of this article, you will have gained valuable insights into the world of ball production, enabling you to appreciate the intricacies behind the balls that bring joy and excitement to sports enthusiasts and leisure seekers alike.

Key Takeaways

1. There are various methods used in ball production, including injection molding, blow molding, compression molding, and rotational molding.

2. Injection molding is the most common technique for producing balls due to its high efficiency, precision, and ability to create complex shapes.

3. Blow molding is suitable for hollow balls and is often used in the production of inflatable balls and toys.

4. Compression molding is typically employed for rubber and solid balls, offering excellent control over material properties and enabling cost-effective production.

5. Rotational molding is primarily used for large and hollow balls, such as those used in water tanks and playground equipment, providing durability and uniform wall thickness.

What are the different methods used in ball production?

Injection Molding

Injection molding is one of the most common methods used in ball production. This process involves melting a plastic material, typically polypropylene or polyethylene, and injecting it into a mold cavity. The molten plastic is then cooled and solidified, resulting in a solid ball shape. Injection molding allows for high production volumes and precise control over ball dimensions.

Blow Molding

Blow molding is another popular technique for manufacturing balls. In this process, a heated plastic tube, called a parison, is placed in a mold cavity. Compressed air is then introduced into the parison, causing it to expand and take the shape of the mold. Once the plastic has cooled, the mold is opened, and the finished ball is ejected. Blow molding is commonly used for producing hollow balls with thinner walls.

Compression Molding

Compression molding involves placing a predetermined amount of material, such as rubber or thermosetting plastics, into a closed mold cavity. The mold is then heated, causing the material to soften and flow into the desired shape. Pressure is applied to compact the material, and it is allowed to cool and harden. Compression molding is suitable for producing balls with complex designs or using materials that cannot be melted.

Rotational Molding

Rotational molding, also known as rotomolding, is a unique process used for ball production. It begins with adding a powdered material, such as polyethylene, into a heated mold. The mold is then rotated slowly, allowing the material to evenly coat the inner surfaces of the mold cavity. As the mold continues to rotate, the plastic gradually melts and fuses together, forming a hollow ball. Rotational molding offers excellent design flexibility and is commonly used for large-sized balls.

Hand Stitching

Hand stitching is a traditional method employed in the production of balls, particularly leather or fabric-based ones. Skilled craftsmen manually sew together multiple panels to create the ball’s spherical shape. The stitching process ensures durability and strength. Hand stitching is often used for footballs, basketballs, and other sports balls that require precise grip and control.

Machine Stitching

Machine stitching is a more efficient alternative to hand stitching. Specialized sewing machines equipped with multiple needles and threads are used to stitch the ball panels together. This method ensures consistent stitch quality and higher production rates compared to manual stitching. Machine stitching is commonly used for mass-producing balls in a cost-effective manner.

Molding Factors

Several factors influence the choice of ball production method. These factors include the desired material properties, manufacturing volume, production speed, cost considerations, and the final application of the ball. Each production method has its advantages and limitations, making it important to carefully evaluate these factors before selecting the most suitable ball production method.

Environmental Impact

Exploring ball production methods also entails considering their environmental impact. Some manufacturing processes, such as injection molding and blow molding, generate plastic waste and consume significant amounts of energy. However, efforts are being made to incorporate sustainable practices in ball production, such as using recycled materials or exploring bio-based alternatives. It is crucial for manufacturers to prioritize eco-friendly methods to minimize the environmental footprint of ball production.

Guides for Choosing the Right Ball Production Method:

- What are the material requirements for the ball?

- What is the expected production volume?

- What are the desired product dimensions and tolerances?

- Does the ball necessitate specific characteristics, such as hollow or solid construction?

- What is the budget for production?

- Is sustainability an important factor in the decision-making process?

Frequently Asked Questions

1. What are the different methods used in ball production?

There are various methods employed in ball production, including hand stitching, machine stitching, thermal bonding, and injection molding.

2. Which method is the most commonly used for producing sports balls?

Machine stitching is the most commonly used method for producing sports balls due to its efficiency and cost-effectiveness.

3. How does hand stitching differ from machine stitching?

Hand stitching involves skilled artisans stitching the panels of the ball together by hand, resulting in a more premium and durable product. Machine stitching, on the other hand, involves automated stitching processes, which are quicker but may not offer the same level of intricacy and precision.

4. What is thermal bonding in ball production?

Thermal bonding is a method that uses heat and pressure to fuse the panels of a ball together. This process creates a seamless and smoother surface, enhancing the overall performance of the ball.

5. What are the advantages of injection molding in ball production?

Injection molding allows for the production of complex designs and intricate patterns. It offers excellent consistency in shape, size, and weight, ensuring uniformity among the produced balls.

6. Are certain ball production methods more suitable for specific sports?

Yes, certain ball production methods are more suitable for specific sports. For example, hand-stitched balls are commonly used in premium footballs, while machine-stitched balls are prevalent in recreational play. Injection-molded balls are popular in sports like basketball and volleyball.

7. How does the choice of ball production method affect the durability of the ball?

The choice of ball production method directly impacts the durability of the ball. Hand-stitched and thermal-bonded balls generally offer greater durability due to their construction techniques, whereas machine-stitched and injection-molded balls might be more susceptible to wear and tear.

8. Which ball production method offers better ball control and performance?

Hand-stitched and thermal-bonded balls often provide better ball control and performance. The hand-stitching technique offers more grip and responsiveness, while thermal bonding ensures a smooth surface for enhanced ball handling.

9. Are there any eco-friendly ball production methods available?

Yes, there are eco-friendly ball production methods available. Some manufacturers use sustainable materials, such as recycled rubber, and implement energy-efficient production processes to reduce the environmental impact of ball production.

10. How can I identify the production method used for a specific ball?

To identify the production method used for a specific ball, you can check the product information provided by the manufacturer or look for visible indications on the ball, such as stitching patterns or seams.

Final Thoughts on Exploring Ball Production Methods

Understanding the various methods involved in ball production is essential for both consumers and sports enthusiasts. The choice of production method directly affects the quality, performance, and durability of the ball. Whether you prioritize premium craftsmanship or cost-efficiency, exploring different production methods can help you make a well-informed decision when purchasing sports balls.

Furthermore, advancements in ball production techniques continue to drive innovation in the sports industry. By considering factors like materials, construction methods, and environmental impact, manufacturers strive to create the optimal ball for each sport. Exploring these production methods not only enhances our appreciation for the artistry behind the creation of sports balls but also allows us to make conscious choices aligned with our specific needs and preferences.