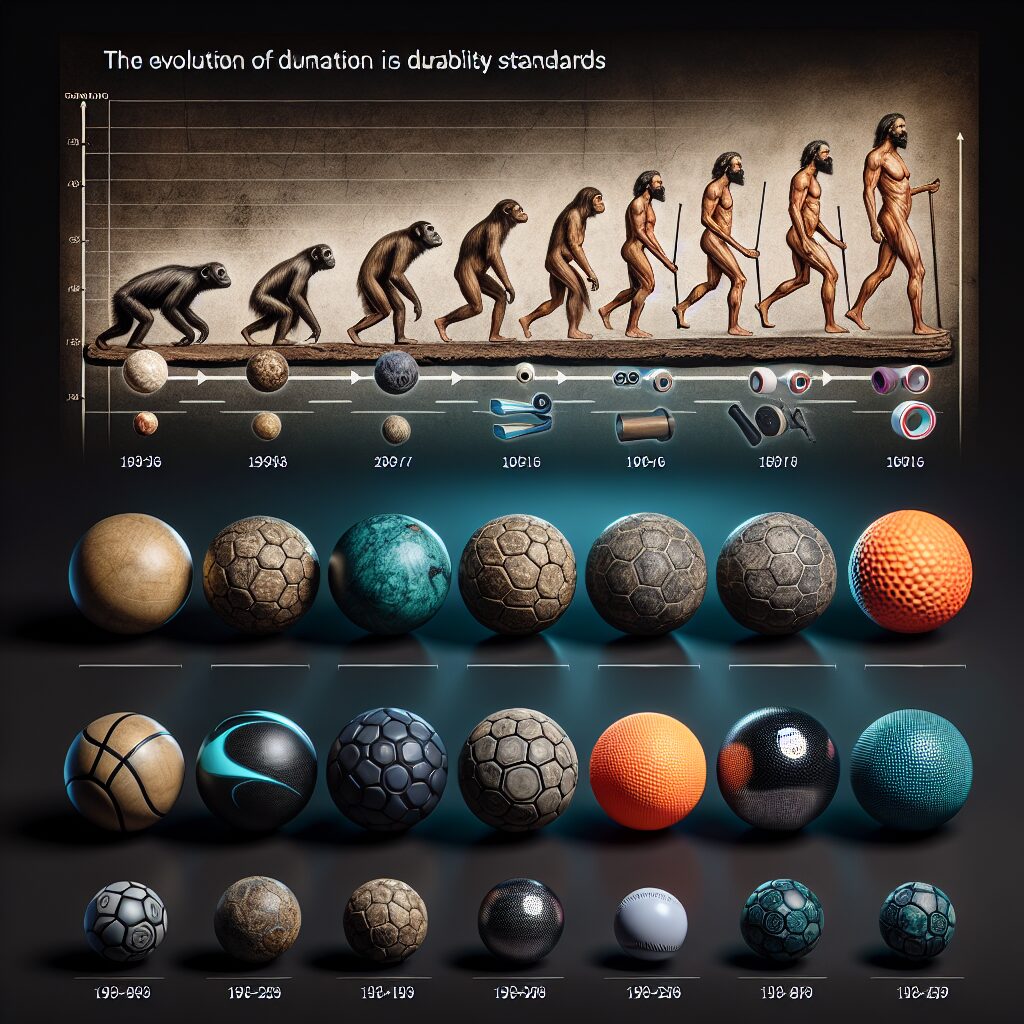

The evolution of durability standards has paved the way for the development of better balls in various industries. Durability, in this context, refers to the ability of a ball to withstand wear and tear over time, ensuring longevity and optimal performance. With advancements in technology and materials, manufacturers have been able to enhance the durability of balls, resulting in improved performance and increased customer satisfaction.

One important aspect of this evolution is the use of advanced materials in ball manufacturing. For instance, in sports such as soccer or basketball, the introduction of synthetic materials, such as composite leather or synthetic rubber, has significantly increased the durability of balls. These materials are designed to withstand harsh playing conditions, including severe weather, rough surfaces, and intense physical contact. As a result, athletes can now rely on more robust and long-lasting balls that can endure the demands of the game.

Moving forward, let’s delve into the key takeaways from the evolution of durability standards. We will explore the impact of durability on various industries, such as sports, manufacturing, and consumer products. Additionally, we will discuss the specific features and technologies that have contributed to the improved durability of balls. By understanding these key takeaways, readers will gain insights into the importance of durability standards and the benefits they bring to the performance and longevity of balls.

Key Takeaways

1. Improved durability standards for sports balls have been developed to address concerns over their longevity and performance, particularly in high-intensity sports such as tennis and soccer. These standards aim to ensure that the balls can withstand rigorous use and maintain their performance characteristics over time.

2. Durability testing protocols now incorporate various factors such as ball weight, air retention, and resistance to deformation. This comprehensive approach helps manufacturers create balls that are more resistant to wear and tear, thereby enhancing their longevity and overall performance on the field or court.

3. The development of advanced materials and manufacturing techniques has played a significant role in improving the durability of sports balls. The use of innovative materials such as synthetic leathers and high-performance rubbers, as well as precision manufacturing techniques, has led to more robust and long-lasting balls that can withstand the demands of intense gameplay.

4. The evolution of durability standards has not only benefited professional athletes but also recreational players. By ensuring that sports balls maintain their performance characteristics for a longer duration, these standards help enhance the overall experience for players at all levels of the game.

5. Ongoing research and development in the field of sports ball durability continue to push the boundaries of what is possible. By leveraging advancements in technology and manufacturing processes, manufacturers can constantly improve the quality and durability of sports balls, leading to better performance, increased player satisfaction, and reduced waste over time.

What are the key factors driving the evolution of durability standards and paving the way for better balls?

Importance of Durability Standards

Durability standards play a crucial role in ensuring the quality and longevity of various products, including balls used in sports and recreational activities. With the evolution of technology and the growing demands of athletes and consumers, it has become paramount to establish and improve durability standards for better balls. This section will delve into the importance of durability standards and how they contribute to the overall performance and safety of balls.

The Evolution of Durability Standards

Over the years, durability standards for balls have undergone significant changes and advancements. This section will explore the key milestones in the evolution of durability standards, including the development of testing methodologies, the establishment of industry regulations, and the incorporation of innovative materials and manufacturing processes to enhance ball durability.

The Role of Technology in Improving Durability Standards

Technological advancements have revolutionized the way durability standards are set and achieved. This section will discuss how cutting-edge technologies, such as advanced materials, computer simulations, and robotic testing, have contributed to raising the bar for durability standards. Additionally, it will explore the impact of technology on the overall performance and lifespan of balls.

Benefits of Enhanced Durability Standards

The implementation of improved durability standards brings numerous benefits to both athletes and consumers. This section will highlight the advantages of better durability standards, such as increased product lifespan, enhanced performance, reduced risk of injury, and cost-effectiveness. Moreover, it will emphasize the positive impact these standards have on sustainability and environmental conservation.

The Collaboration of Industry Stakeholders

Creating and implementing durability standards for better balls requires a collaborative effort involving various industry stakeholders. In this section, we will explore how manufacturers, sports governing bodies, standardization organizations, and researchers work together to establish and update durability standards. It will also discuss the role of consumer feedback and market trends in driving the evolution of these standards.

The Future of Durability Standards

Looking ahead, the evolution of durability standards for better balls is a continuous process driven by research, innovation, and changing industry needs. This section will outline potential future developments in durability standards, including the incorporation of smart technologies, customization options, and further improvements in testing methodologies. It will also emphasize the importance of staying updated and adaptable in a rapidly changing sporting goods industry.

Tips for Integrating Enhanced Durability in Ball Selection:

- Consider the specific demands of the sport or activity to ensure the ball meets the required durability standards.

- Research and choose balls from reputable manufacturers who adhere to recognized durability standards.

- Read customer reviews and testimonials to gain insight into the durability and performance of a particular ball.

- Take into account the playing surface and conditions to select a ball suitable for optimum performance and longevity.

- Properly maintain and store balls to extend their lifespan and preserve their durability.

Frequently Asked Questions

1. What are durability standards for balls and why are they important?

Durability standards for balls refer to the specific requirements and criteria that determine the longevity and resistance of a ball. These standards are important as they ensure that the balls can withstand the demands of various sports and prevent premature wear or failure.

2. How do durability standards evolve over time?

Durability standards evolve over time through extensive research, technological advancements, and insights gained from analyzing the durability of existing balls. Manufacturers and governing bodies closely monitor performance data and user feedback to identify areas for improvement, resulting in the development of more robust and long-lasting balls.

3. What factors contribute to the evolution of durability standards?

Several factors contribute to the evolution of durability standards. These include advancements in materials science, such as the introduction of more durable synthetic fibers and coatings. Additionally, feedback from players, coaches, and officials helps identify weaknesses in existing balls, prompting manufacturers to enhance the durability of future designs.

4. Are the new balls meeting the updated durability standards more expensive?

The cost of balls meeting updated durability standards can vary depending on various factors such as the manufacturing process, materials used, and brand reputation. While some new balls may come at a higher price due to advanced technologies, increased durability often translates to a longer lifespan, ultimately providing better value for money in the long run.

5. How do durability standards impact player performance?

Durability standards directly impact player performance by ensuring that the balls maintain their desired characteristics throughout the game. With improved durability, players can trust the consistency and reliability of the ball, allowing them to focus on their skills and strategies rather than worrying about unforeseen issues with the ball’s performance.

6. How are durability standards tested?

Durability standards are tested through rigorous laboratory experiments and field trials. These tests involve subjecting the balls to simulated game conditions, extreme temperatures, humidity, and impact testing to evaluate their durability, resilience, and resistance to wear and tear.

7. Are durability standards the same for all sports?

No, durability standards can vary across different sports based on the specific requirements and demands of each game. For example, balls used in contact sports like soccer or rugby may need to meet higher durability standards compared to those used in non-contact sports like golf or tennis.

8. How do durability standards benefit both professionals and amateurs?

Durability standards benefit both professionals and amateurs alike by ensuring a consistent playing experience. Professionals can rely on high-quality and long-lasting balls that enhance their performance, while amateurs can enjoy improved durability, reduced replacement costs, and a more enjoyable gameplay experience.

9. Can the evolution of durability standards impact the environment?

Yes, the evolution of durability standards can have a positive impact on the environment. By producing more durable balls, the need for frequent replacements and disposal is reduced, leading to less waste generation. Additionally, a longer lifespan for balls reduces the overall carbon footprint associated with their manufacturing and distribution processes.

10. How can consumers identify balls that meet updated durability standards?

Consumers can identify balls that meet updated durability standards by looking for certifications or endorsements from renowned sports governing bodies and industry associations. Additionally, researching product specifications and customer reviews can provide valuable insights into a ball’s durability and performance.

Final Thoughts

The evolution of durability standards in the manufacturing of balls marks a significant step towards enhancing the sporting experience for both professionals and amateurs. By addressing concerns related to premature wear, breakage, or erratic performance, these updated standards ensure a level playing field and consistency, allowing athletes to focus on refining their skills and strategies.

Furthermore, the positive environmental impact of increased durability cannot be understated. The reduction in waste generation and carbon footprint associated with manufacturing and disposal of balls not only benefits the planet but also encourages sustainability within the sports industry. As durability standards continue to evolve, we can expect the emergence of even better balls that push the boundaries of performance while prioritizing longevity and environmental responsibility.