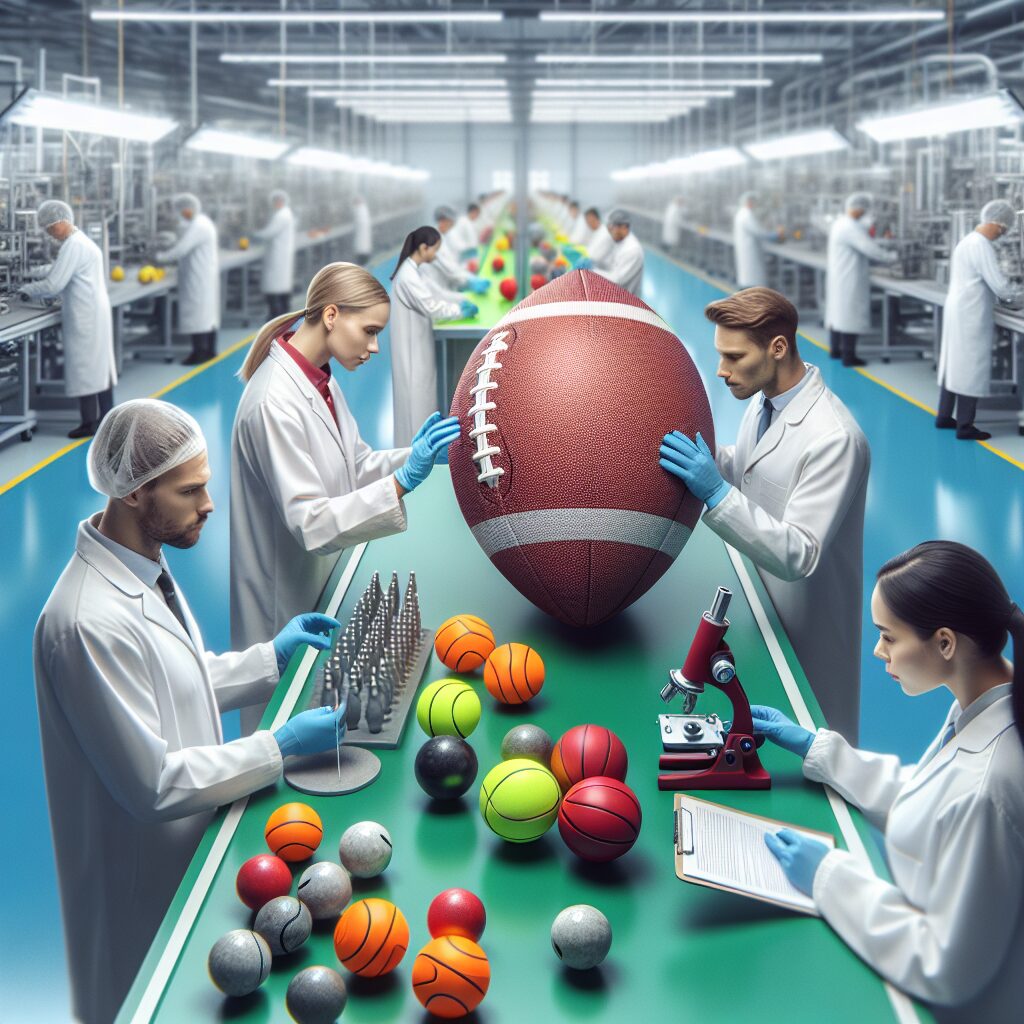

Ensuring Quality Control in Sports Ball Production is of utmost importance in the manufacturing industry. With the growing demand for sports balls across various disciplines, it is crucial to maintain high standards in the production process.

One unique insight related to this topic is the impact that quality control has on the performance and safety of athletes. Each sports ball, whether it be a soccer ball, basketball, or tennis ball, undergoes a rigorous testing process to ensure its reliability, durability, and consistency. These aspects directly affect the accuracy of play, providing a level playing field for athletes at all levels of competition. Additionally, the safety of athletes is paramount, and proper quality control measures in ball production help minimize the risk of injuries caused by defective or substandard balls.

Moving forward, let’s delve into the key takeaways regarding quality control in sports ball production. We will explore the various steps involved in the manufacturing process, such as material selection, design considerations, and testing procedures. In doing so, we can gain a deeper understanding of the meticulous measures taken to deliver top-notch sports balls to athletes worldwide.

Key Takeaways

1. Quality control is crucial in sports ball production, as it directly affects the performance, durability, and safety of the balls.

2. The process of quality control involves rigorous testing and inspections at various stages, including the raw material selection, manufacturing, and final product evaluation.

3. Advanced technologies such as x-ray machines, robotic systems, and pressure testing equipment are employed to ensure the balls meet strict quality standards.

4. Quality control protocols also encompass criteria like weight, size, shape, texture, bounce, and air retention, which are essential for maintaining consistent and fair play.

5. Continuous improvement and research are vital in the field of sports ball production, as manufacturers strive to enhance performance, accuracy, and reliability while meeting safety regulations.

How can you ensure quality control in sports ball production?

1. Establishing strict manufacturing protocols

One crucial aspect of ensuring quality control in sports ball production is to establish strict manufacturing protocols. These protocols should outline each step of the production process, including raw material selection, cutting and shaping, stitching, and quality inspections. By creating a detailed roadmap for the production process, manufacturers can ensure consistency and identify any potential issues before they affect the final product.

2. Implementing thorough quality inspections

To maintain high standards, regular quality inspections should be conducted throughout the production process. These inspections can identify any defects or inconsistencies in the sports balls, allowing manufacturers to make necessary adjustments or rejections. Inspections should cover factors such as size, weight, shape, stitching quality, and durability. By implementing thorough quality inspections, manufacturers can catch any imperfections and ensure that only the highest quality sports balls are being produced.

3. Utilizing advanced testing equipment

Utilizing advanced testing equipment is essential for quality control in sports ball production. Equipment such as ball pressure testers, impact testers, and bounce testers can be used to assess the performance and durability of the balls. These tests simulate real-life game conditions, ensuring that the sports balls meet the required standards. By investing in and utilizing advanced testing equipment, manufacturers can have confidence in the quality of their products.

4. Training and educating production staff

Quality control starts with the people involved in the production process. Providing comprehensive training and education to the production staff is crucial for maintaining high standards. Staff members should be well-versed in the manufacturing protocols, quality standards, and testing procedures. By ensuring that every team member understands their role and responsibilities in the quality control process, manufacturers can reduce the risk of errors or oversights.

5. Collaborating with certified suppliers

The quality of sports balls heavily relies on the quality of the materials used. Collaborating with certified suppliers who adhere to standards and regulations is vital for ensuring quality control in sports ball production. Manufacturers should conduct thorough research and choose suppliers who have a track record of delivering high-quality materials. By establishing strong partnerships with reliable suppliers, manufacturers can ensure consistent quality throughout the production process.

6. Implementing continuous improvement processes

Quality control is a continuous process that requires ongoing evaluation and improvement. Manufacturers should implement feedback systems, collect data on product performance, and assess customer satisfaction to identify areas for enhancement. By continuously seeking ways to improve the production process, manufacturers can stay ahead of competitors and consistently deliver top-notch sports balls to the market.

How to ensure quality control in sports ball production:

- Establish strict manufacturing protocols

- Implement thorough quality inspections

- Utilize advanced testing equipment

- Train and educate production staff

- Collaborate with certified suppliers

- Implement continuous improvement processes

Frequently Asked Questions

1. What is quality control in sports ball production?

Quality control in sports ball production refers to the processes and measures implemented to ensure that the sports balls produced meet the set standards of quality, durability, performance, and safety.

2. Why is quality control important in sports ball production?

Quality control is crucial in sports ball production to maintain consistency in product quality and performance. It ensures that the balls meet the requirements of athletes, governing bodies, and customers, reducing the risk of defects and enhancing player experience.

3. What are the key elements of quality control in sports ball production?

The key elements of quality control in sports ball production include rigorous material testing, strict adherence to manufacturing standards, thorough inspections throughout the production process, and appropriate quality assurance measures.

4. How can manufacturers ensure quality control in sports ball production?

To ensure quality control, manufacturers can employ trained quality control personnel, implement effective quality management systems, conduct regular product inspections, and continuously improve production processes based on feedback and data analysis.

5. What are some common quality issues in sports ball production?

Common quality issues in sports ball production include uneven weight distribution, improper stitching, air leakage, substandard materials, inconsistent bounce, poor grip, and inadequate durability.

6. What testing procedures are used in quality control for sports balls?

Testing procedures in quality control for sports balls often involve various tests such as weight and size verification, pressure and inflation tests, impact and drop tests, abrasion resistance tests, and performance assessments under different playing conditions.

7. How does quality control impact the cost of sports ball production?

While implementing quality control measures may increase production costs initially, it helps minimize the risks of defects, product recalls, customer dissatisfaction, and legal issues. In the long run, effective quality control can lead to cost savings by improving overall efficiency and reputation.

8. What regulations or standards exist for sports ball production quality control?

Several international and national standards, such as ISO 9001 (Quality Management System), ASTM International standards, and specific sports governing bodies’ regulations, provide guidelines and requirements for quality control in sports ball production.

9. How does quality control contribute to player safety in sports?

Quality control plays a significant role in ensuring player safety by identifying and eliminating potential hazards in sports ball production. It helps prevent accidents, injuries, and equipment failure during gameplay, providing athletes with reliable and safe sports balls.

10. Can quality control be applied to all types of sports balls?

Yes, quality control is applicable to a wide range of sports balls, including but not limited to footballs, basketballs, soccer balls, baseballs, volleyballs, tennis balls, golf balls, and cricket balls. Each type has specific quality requirements to meet its unique playing characteristics.

Final Thoughts on Ensuring Quality Control in Sports Ball Production

Quality control is of utmost importance in sports ball production as it ensures the consistent delivery of high-quality balls to athletes and sports enthusiasts. By strictly adhering to quality control measures and standards, manufacturers can enhance player experience, maintain product reliability, and uphold athlete safety.

Fostering effective quality control practices involves continuous improvement, embracing advanced manufacturing technologies, and being responsive to customer feedback. Combining expertise, precision, and innovation, the sports ball industry can consistently produce exceptional balls that meet the exacting demands of sports professionals and promote the growth and integrity of the games we love.