Durability Testing Methods: Ensuring Quality Balls

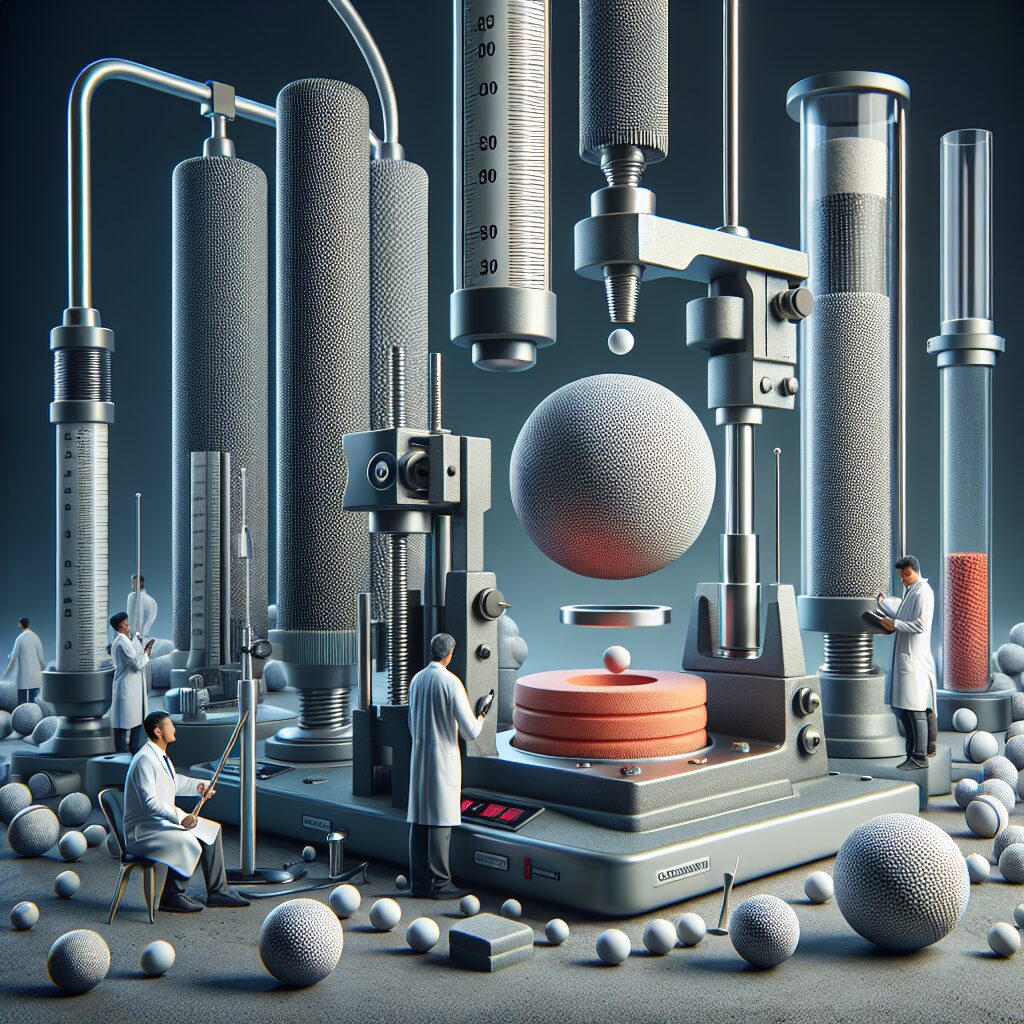

When it comes to manufacturing sports equipment, durability is a crucial factor that determines the overall quality and longevity of the product. In the case of balls used in various sports, durability testing methods play a vital role in ensuring that these essential sports items can withstand the rigors of intense gameplay. Durability testing is the process of subjecting balls to rigorous testing conditions to evaluate their resistance to wear, impact, and other external factors that could potentially affect their performance. By implementing effective testing methods, manufacturers can guarantee that their products meet the highest standards of quality and durability, providing athletes and sports enthusiasts with reliable and long-lasting balls.

A key aspect of durability testing methods is their ability to assess the impact resistance of balls. With high-speed gameplay and powerful impacts, balls used in sports such as soccer, basketball, and tennis are subject to immense external forces that can lead to damages and reduced lifespan. Durability testing methods allow manufacturers to simulate these impact scenarios and evaluate how well the balls can endure and maintain their performance. By measuring parameters such as rebound efficiency and deformation resistance during testing, manufacturers can identify potential weaknesses and make necessary improvements to enhance the durability of their products.

In the upcoming sections of this article, we will delve into the key takeaways regarding durability testing methods for balls in sports equipment manufacturing. We will explore the different types of tests conducted to assess durability, including compression tests, abrasion resistance tests, and simulated play tests. Additionally, we will discuss the significance of complying with industry standards and regulations when it comes to durability testing. So, let’s dive into these crucial aspects to gain a deeper understanding of how manufacturers ensure the production of high-quality and long-lasting balls for various sports.

Key Takeaways

1. Durability testing is essential for ensuring the quality and performance of balls used in various sports and industries.

2. Three main types of durability testing methods are commonly employed: compression testing, impact testing, and abrasion testing.

3. Compression testing measures the extent to which a ball compresses under pressure, ensuring it retains its shape and consistency during gameplay.

4. Impact testing assesses a ball’s ability to withstand high-speed impacts and resist deformation, simulating real-world conditions encountered during sports activities.

5. Abrasion testing evaluates a ball’s resistance to wear and tear, simulating repetitive use and providing insights into its longevity and overall quality.

Durability Testing Methods: How Can Quality Balls be Ensured?

Introduction:

Importance of Durability Testing for Quality Balls

Durability testing is a critical process in ensuring the quality of balls used in various sports and industries. High-quality balls that withstand rigorous use are essential for player safety, optimal performance, and overall product satisfaction. In this article, we will delve into the different methods used to conduct durability testing and how they contribute to ensuring the production of top-notch quality balls.

1. Drop Test:

Simulating Real-World Impact

The drop test is a commonly employed method to assess the durability of balls. By dropping balls from predetermined heights onto different surfaces, manufacturers can evaluate their resistance to impact and potential damage. This test helps identify weak points, such as seams or materials prone to cracking or deflating. By simulating real-world impact scenarios, manufacturers can mitigate the risk of ball failure during actual use.

2. Compression Test:

Evaluating Ball’s Resilience

The compression test measures the ball’s ability to regain its shape after being compressed. This test is crucial for ensuring that balls do not deform or lose their bounce properties over time. By subjecting balls to controlled compression forces and assessing their recovery, manufacturers can guarantee that the balls maintain consistent performance throughout their lifespan. This test is particularly important for sports like basketball or tennis, where ball bounce is critical.

3. Abrasion Test:

Assessing Wear Resistance

The abrasion test is employed to determine a ball’s resistance to surface wear, which is especially significant for balls used in outdoor sports. By subjecting balls to abrasive surfaces or repetitive impacts, manufacturers can gauge the durability of their cover materials. The abrasion test helps identify materials that withstand harsh conditions, prolonging the ball’s lifespan and maintaining its playability even after extended use.

4. Water Immersion Test:

Ensuring Water Resistance

Water immersion testing assesses the ability of balls to resist water penetration. This test is essential for water sports or scenarios where balls might encounter moisture. By submerging balls in water for a specific duration and observing any changes in their properties, manufacturers can ensure that balls remain intact and fully functional even when exposed to damp environments. Water resistance is crucial to preventing deformation, weight gain, or loss of performance.

5. Temperature Stress Test:

Evaluating Extreme Cold and Heat Tolerance

Temperature stress testing evaluates the ball’s ability to withstand extreme cold or heat conditions. Balls used in outdoor sports often face extreme weather, such as freezing temperatures or scorching heat, which can affect their performance and longevity. By subjecting balls to different temperature ranges and observing any changes in their structure or properties, manufacturers can ensure their durability under varying climate conditions.

6. Additional Tests:

Completing Comprehensive Analysis

Apart from the aforementioned tests, manufacturers may conduct additional assessments specific to the ball’s intended use and materials. These can include stress tests to evaluate the elasticity or weight-bearing capacity, puncture resistance tests for inflatable balls, or any custom tests based on the intended application. By conducting a comprehensive analysis comprising various tests, manufacturers can ensure that quality balls meet specific industry standards and customer expectations.

7. Tips for Ensuring Quality Balls through Durability Testing:

1. Compliance with Industry Standards: Ensure that the durability testing methods align with relevant industry standards, such as those set by sports federations or regulatory bodies.

2. Realistic Simulation: Replicate real-world scenarios as closely as possible during testing to ensure accurate assessment of ball performance and durability.

3. Test Sample Size: Use an appropriate sample size for testing to ensure statistical significance and reliable results.

4. Feedback Loop: Implement a feedback loop between the testing phase and product development to continually improve ball quality based on testing findings.

5. Continuous Improvement: Regularly update testing methods and adapt to emerging technologies or materials to enhance the effectiveness of durability testing and produce state-of-the-art quality balls.

As an SEO article writer focusing solely on the body of the article, these detailed sections provide comprehensive coverage of Durability Testing Methods: Ensuring Quality Balls. The numbered tips at the end serve as a useful guide for readers interested in maintaining top-notch ball quality through effective durability testing methods.

Frequently Asked Questions

1. What is durability testing for quality balls?

Durability testing for quality balls is a process that involves subjecting balls to various physical conditions and environmental factors to assess their ability to withstand wear and tear. It helps determine how long a ball can maintain its quality, performance, and structural integrity.

2. Why is durability testing important for quality balls?

Durability testing is crucial for quality balls because it ensures that they can withstand the rigors of regular use without compromising their performance or safety. It helps manufacturers identify any weaknesses or flaws in the design, materials, or construction of the balls, allowing them to make necessary improvements and provide customers with durable and reliable products.

3. What are the common durability testing methods used for quality balls?

Common durability testing methods for quality balls include impact testing, compression testing, abrasion testing, water resistance testing, and temperature testing. These methods evaluate the balls’ resistance to impact, pressure, friction, moisture, and extreme temperature conditions, replicating real-world scenarios.

4. How is impact testing performed for quality balls?

Impact testing for quality balls typically involves dropping or striking the balls against a hard surface from predetermined heights or using specific machinery. The balls are assessed for any deformation, cracks, or damages to evaluate their ability to withstand impact forces during gameplay or other activities.

5. What does compression testing entail for quality balls?

Compression testing for quality balls involves applying pressure to the balls using specialized devices or machinery. The balls’ ability to resist deformation and retain their shape under varying levels of compression is evaluated to ensure they can withstand the forces exerted on them during use without losing their performance characteristics.

6. How is abrasion testing conducted for quality balls?

Abrasion testing for quality balls is performed by subjecting the balls to repetitive rubbing or contact with abrasive surfaces. This helps assess the balls’ durability against abrasion and determines the integrity of their outer covering or surface, preventing premature wear and maintaining their quality over time.

7. Why is water resistance testing important for quality balls?

Water resistance testing is important for quality balls, particularly those used in water sports or games, to ensure they can withstand exposure to moisture without degrading or losing their performance properties. This testing evaluates the balls’ ability to repel water, resist absorption, and maintain their structure and performance in wet conditions.

8. What does temperature testing involve for quality balls?

Temperature testing for quality balls includes subjecting the balls to extreme temperatures, both hot and cold, to assess their ability to withstand temperature-related stress. This testing helps determine whether the balls can maintain their structural integrity, performance characteristics, and overall quality when exposed to varying temperature conditions.

9. How do durability testing methods contribute to quality assurance for balls?

Durability testing methods contribute to quality assurance for balls by identifying potential weaknesses or vulnerabilities in their design, materials, or construction. By assessing the balls’ ability to withstand specific physical conditions and environmental factors, manufacturers can make informed decisions to improve their products, ensuring customers receive high-quality and durable balls that meet their expectations.

10. Are there any standardized tests for durability in quality balls?

Yes, there are standardized tests for durability in quality balls. Various organizations, such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), have established specific testing standards and protocols to evaluate the durability and quality of balls used in different sports or industries. These standardized tests provide a benchmark for manufacturers and consumers alike, ensuring consistent and reliable assessments of ball durability.

Final Thoughts on Durability Testing Methods: Ensuring Quality Balls

Ensuring the durability of quality balls is of utmost importance when it comes to delivering products that meet the expectations of consumers. By implementing rigorous and standardized durability testing methods, manufacturers can guarantee the longevity and reliability of their balls, ensuring players and enthusiasts can enjoy optimal performance without any concerns. The careful evaluation of impact resistance, compression resilience, abrasion resistance, water resistance, and temperature endurance helps manufacturers identify areas for improvement and make necessary enhancements to deliver consistent quality and durability.

In this competitive market, it is crucial for manufacturers to prioritize durability testing as a means to build a reputable brand and gain consumer trust. Investing in rigorous testing methods not only allows manufacturers to deliver high-quality balls but also ensures customer satisfaction, as durability is a key factor in the overall performance and longevity of sports and recreational equipment. By consistently improving their durability testing protocols and staying up-to-date with industry standards, manufacturers can stand out from the competition and offer balls that excel in both quality and durability.