Durability assessment is a crucial metric when it comes to evaluating the effectiveness and long-term performance of a ball. Whether it’s used in sports, industrial applications, or everyday life, a ball’s durability can greatly affect its usability and lifespan. Essentially, durability assessment refers to the process of evaluating a ball’s ability to withstand various types of stress and maintain its functionality over time.

Understanding the importance of durability assessment is essential, as it can have significant impacts on a ball’s performance and longevity. For instance, in the sports industry, a durable ball is vital to ensure fair play and consistent performance. In sports such as soccer or basketball, players heavily rely on the ball’s durability to accurately kick or shoot, as well as withstand repeated impacts and rough handling during intense gameplay.

Moving forward, this article will delve into the key takeaways related to durability assessment. We will explore the factors that contribute to a ball’s durability, discuss common testing methods used to assess its robustness, and highlight the implications of durability assessment in various industries. By examining these key takeaways, readers will gain a comprehensive understanding of the significance of durability assessment and its impact on ball performance and longevity.

Key Takeaways

Durability assessment is a critical metric for evaluating the quality and performance of balls.

1. Material durability plays a crucial role in ball performance:

Durability, often measured by impact resistance and abrasion resistance, directly affects the lifespan of a ball. The materials used in the construction of a ball need to endure repeated impacts and resist wear and tear to ensure a longer-lasting product.

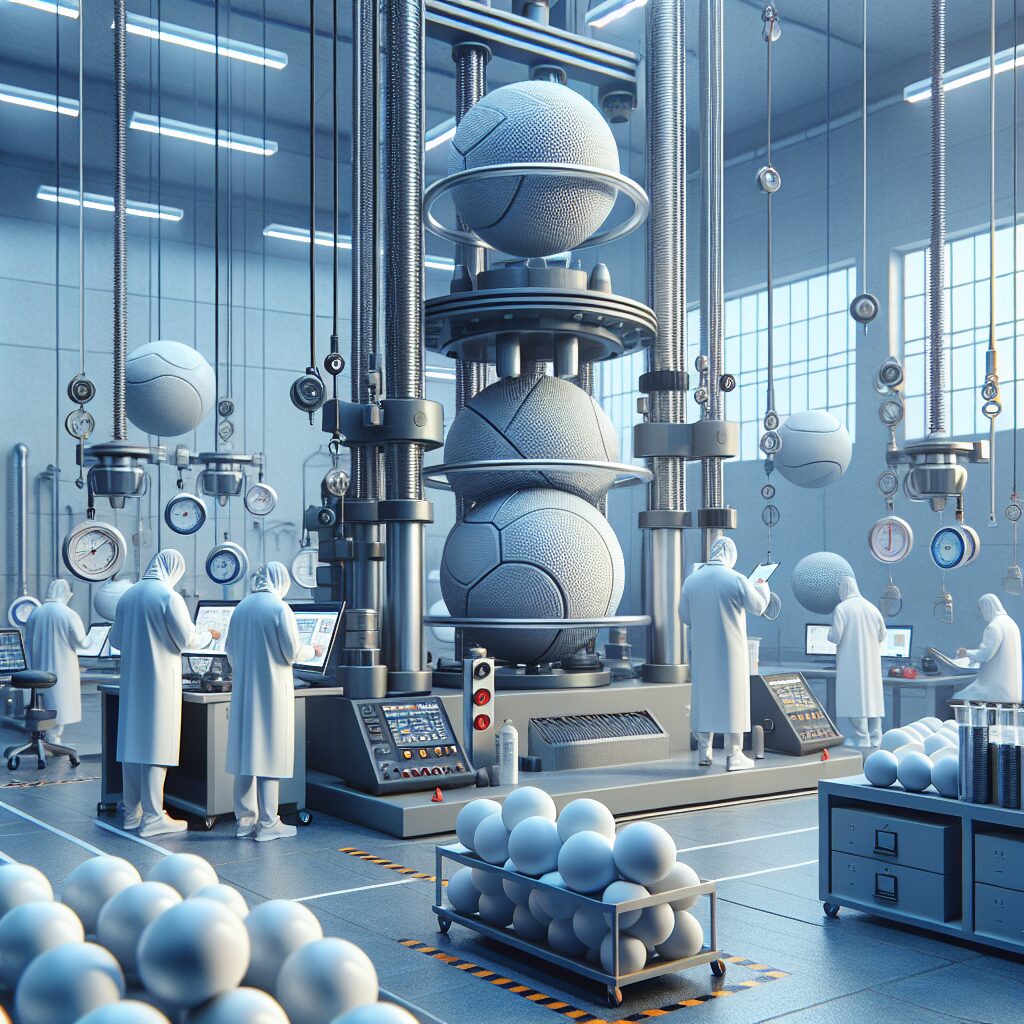

2. Proper manufacturing techniques are essential for ball durability:

The manufacturing process significantly influences the durability of a ball. Factors like the selection of materials, molding techniques, and quality control procedures can all impact the final durability of the ball. Implementing proper manufacturing techniques is vital to ensure durability.

3. Ball durability affects the game experience:

A durable ball ensures a consistent performance over time, providing users with a better game experience. Whether it’s in sports like soccer, basketball, or tennis, a durable ball retains its characteristics, bounce, and flight pattern for longer, enhancing the playability and enjoyment of the game.

4. Ball durability promotes cost-effectiveness:

A ball that is durable and can last through multiple uses proves to be more cost-effective in the long run. Investing in high-quality, durable balls eliminates the need for frequent replacements, saving money for both consumers and organizations that use balls regularly.

5. Durability testing helps in product improvement:

Conducting rigorous durability testing on balls helps manufacturers identify weaknesses and areas for improvement in the product. By understanding how balls perform under various conditions and usage scenarios, manufacturers can enhance their designs and materials to create more durable and resilient balls.

Durability Assessment: Why is it a Crucial Ball Metric for Your Business?

Understanding the Importance of Durability Assessment

Durability assessment plays a crucial role in evaluating the long-term performance and reliability of products, including ball metrics. By conducting a comprehensive evaluation of a ball’s durability, manufacturers and businesses can ensure that their products meet the required quality standards and are able to withstand the test of time.

The Impact of Durability on Ball Performance

When it comes to ball metrics, durability directly correlates with performance. A ball’s ability to maintain its shape, resistance to wear and tear, and durability against different environmental factors are all key determinants of its performance. By conducting proper durability assessment, businesses can identify potential weaknesses and make necessary improvements to enhance the overall performance of their products.

Factors to Consider in Durability Assessment

Several factors contribute to the assessment of a ball’s durability. These include the materials used, manufacturing processes, intended use, environmental conditions, and anticipated stress levels during operation. Each of these aspects needs to be carefully evaluated to ensure the production of durable balls that meet the specific requirements of customers.

Methods and Techniques for Durability Assessment

There are various methods and techniques available for evaluating the durability of ball metrics. These include accelerated durability testing, simulated usage testing, fatigue testing, environmental testing, and field performance monitoring. Each approach offers specific insights into the behavior and performance of balls under different conditions, allowing businesses to make data-driven decisions to improve their product durability.

Benefits of Conducting Durability Assessment

The benefits of conducting durability assessment for ball metrics are numerous. It helps businesses improve product quality, reduce warranty claims and product returns, enhance customer satisfaction, and maintain a competitive edge in the market. By investing in durability assessment, companies can build a reputation as a reliable and trustworthy supplier in their industry.

Tips for Effective Durability Assessment

1. Assess the expected stress levels and environmental conditions that your balls will encounter during their lifespan.

2. Incorporate accelerated durability testing methods to simulate real-world usage conditions and evaluate product performance.

3. Regularly monitor and analyze field performance data to identify potential durability issues and make timely improvements.

4. Collaborate with material scientists and engineers to select appropriate materials and manufacturing processes that enhance product durability.

5. Continuously review and update your durability assessment strategies to stay ahead of industry requirements and technological advancements.

In conclusion, durability assessment is a crucial ball metric that should not be overlooked by businesses. By understanding the significance of durability and implementing effective assessment methods, companies can ensure the production of durable ball metrics that meet customer expectations and contribute to long-term success.

Frequently Asked Questions

1. What is Durability Assessment: A Crucial Ball Metric?

Durability Assessment: A Crucial Ball Metric is a method used to evaluate the durability and sustainability of a ball. It involves assessing various factors such as material quality, construction, and performance over time.

2. Why is Durability Assessment important for balls?

Durability Assessment is crucial for balls as it ensures that they are able to withstand wear and tear, maintain performance, and have a longer lifespan. It helps manufacturers understand the longevity of their products and enables customers to make informed purchasing decisions.

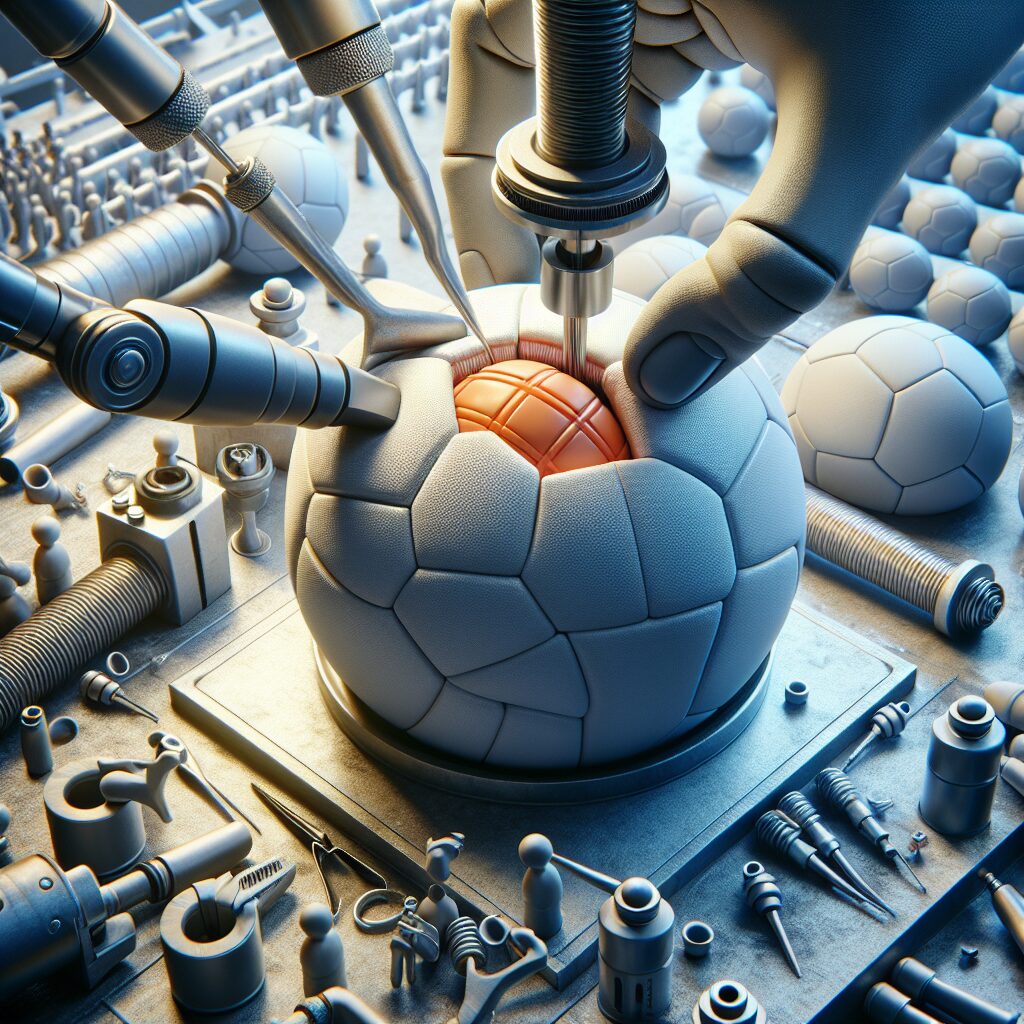

3. How is Durability Assessment carried out?

Durability Assessment involves subjecting balls to various tests and simulations to assess their performance under different conditions. These tests may include impact resistance, deformation analysis, abrasion testing, and durability modeling.

4. What are the key factors considered in Durability Assessment?

Key factors considered in Durability Assessment include material strength, stitching quality, air retention, water resistance, shape retention, and overall structural integrity of the ball. These factors play a significant role in determining the ball’s durability.

5. What are the benefits of conducting Durability Assessment?

Conducting Durability Assessment provides several benefits. It helps manufacturers identify potential design flaws or weaknesses in their products, allows for product improvements, enhances customer satisfaction, reduces the risk of warranty claims, and ensures consistent product quality.

6. Can Durability Assessment vary for different types of balls?

Yes, Durability Assessment can vary for different types of balls due to their varying construction, materials, and intended use. Balls used in specific sports or activities may have different requirements and, therefore, may undergo different testing methods during the assessment.

7. How does Durability Assessment impact the cost of balls?

Durability Assessment can impact the cost of balls as it involves additional testing, research, and development efforts. Balls that undergo thorough Durability Assessment tend to be of higher quality, have longer lifespans, and may be priced slightly higher to reflect the added value and durability they offer.

8. Are there any industry standards for Durability Assessment?

Yes, there are industry standards for Durability Assessment, depending on the specific type of ball. International organizations and regulatory bodies often define guidelines, test methods, and performance criteria to ensure consistency and reliability in assessing ball durability.

9. Does the Durability Assessment affect the performance of a ball?

Yes, the Durability Assessment can have an impact on a ball’s performance. A durable ball tends to maintain its shape, bounce, grip, and other performance characteristics over time. It ensures that the ball remains reliable and performs as expected, even with extended use.

10. How can consumers benefit from Durability Assessment information?

Consumers can benefit from Durability Assessment information by making informed purchasing decisions. By understanding the durability and quality of a specific ball, consumers can choose products that offer the best value for their money, meet their performance expectations, and have a longer lifespan.

Final Thoughts: Durability Assessment: A Crucial Ball Metric

In conclusion, Durability Assessment is an essential metric for evaluating the quality, longevity, and performance of balls. It ensures that manufacturers produce durable products, helps customers make informed choices, and drives overall improvement in ball design and manufacturing processes.

By conducting thorough Durability Assessments, stakeholders in the ball industry can ensure consistent quality, reduce warranty claims, enhance customer satisfaction, and promote sustainable practices. Implementing industry standards and sharing Durability Assessment information empowers consumers and fosters a healthier and more reliable sports and recreational equipment market.