Continuous Improvement: Enhancing Ball Quality

In the dynamic world of manufacturing and production, the concept of continuous improvement has become increasingly significant. Continuous improvement refers to an ongoing process of enhancing efficiency, productivity, and quality within an organization. With its roots in the renowned Japanese management philosophy of Kaizen, continuous improvement has found its way into various industries seeking to optimize their operations. In the sporting goods industry, specifically in the realm of ball manufacturing, the need for continuous improvement is paramount in ensuring top-notch ball quality.

The impact of continuous improvement on ball quality is undeniable. By focusing on refining the manufacturing processes, material selection, and design techniques, manufacturers can consistently raise the bar when it comes to ball quality. This, in turn, leads to enhanced performance, durability, and overall customer satisfaction. Moreover, continuous improvement allows manufacturers to stay ahead in a fiercely competitive market by identifying and rectifying any shortcomings or inefficiencies. By continuously seeking innovative solutions and embracing new technologies, ball manufacturers can meet and exceed consumers’ ever-growing expectations.

Looking ahead, let’s delve into the key takeaways from this discussion. Firstly, we will explore the various strategies and methodologies employed in continuous improvement practices for ball manufacturing. From Lean Manufacturing principles to Six Sigma methodologies, we will examine how these approaches can revolutionize the industry. Secondly, we will highlight the importance of quality control systems and their role in ensuring the consistency and reliability of ball production. Lastly, we will consider the future prospects of continuous improvement in the ball manufacturing industry and how it can contribute to evolving trends and demands. Stay tuned for an insightful exploration of continuous improvement’s impact on ball quality and the exciting possibilities it brings to the table.

Key Takeaways

1. Continuous improvement practices are crucial for enhancing the quality of balls in sports such as golf, soccer, and tennis. These practices involve a multi-step process that includes testing, analyzing data, and implementing changes to overcome any weaknesses or limitations in current designs.

2. Quality control and performance consistency are key factors in ball production. Manufacturers employ advanced technologies and rigorous testing methods to ensure that every ball meets the required standards and specifications. This process involves assessing factors such as durability, flight trajectory, and impact absorption to minimize inconsistencies and optimize performance.

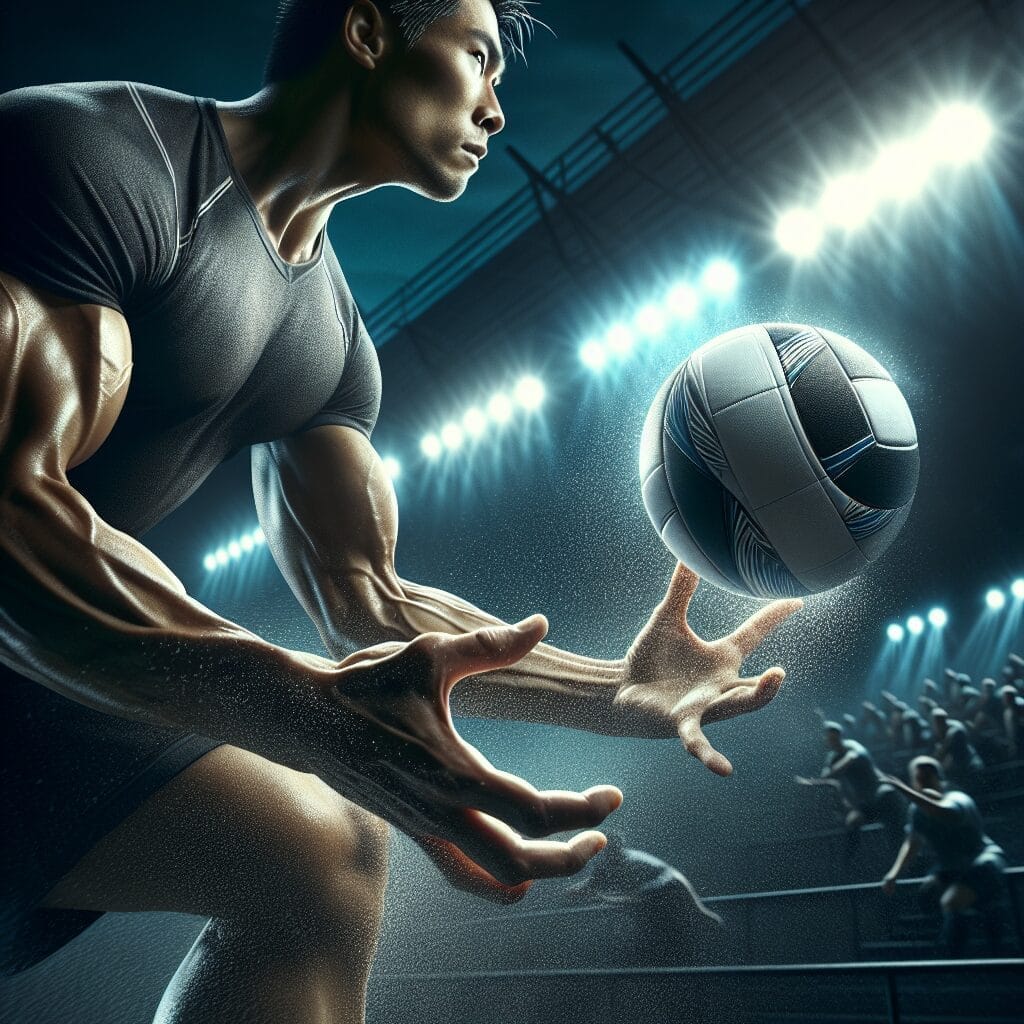

3. Collaboration between manufacturers and athletes is essential throughout the continuous improvement process. Athletes provide valuable insights based on their experience and play style, which manufacturers can utilize to refine existing designs or develop new innovations. This feedback loop helps ensure that the final product meets the specific needs and preferences of the players.

4. Continuous improvement extends beyond the initial design and production phase. Manufacturers also explore ways to improve sustainability by focusing on eco-friendly materials, energy-efficient manufacturing processes, and recycling initiatives. This commitment to sustainability aligns with global efforts to reduce the environmental impact of production and consumption.

5. The continuous improvement journey is ongoing, driven by an unwavering commitment to innovation. Manufacturers consistently strive to improve ball performance, durability, and safety. By embracing new technologies, materials, and design strategies, they aim to push the boundaries of what is possible, benefiting athletes and sports enthusiasts worldwide.

How can Continuous Improvement Enhance Ball Quality?

The Importance of Ball Quality in Sports

Ball quality plays a vital role in various sports, such as soccer, basketball, tennis, and cricket. It directly affects the game’s performance, accuracy, and overall player experience. Therefore, continuous improvement techniques are necessary to enhance the quality of balls used in these sports.

Identifying Current Ball Quality Issues

Before implementing any improvement strategies, it is crucial to identify the existing ball quality issues. This can be done through rigorous testing and analysis, considering factors like material durability, bounce consistency, grip, and flight accuracy. Understanding the specific areas that require enhancement will guide the improvement process.

Design and Material Enhancements

Optimizing ball quality involves focusing on design and material enhancements. Conducting research and development to discover new materials or modifying existing ones can significantly improve ball performance. Exploring cutting-edge technologies and design features can lead to advancements like better aerodynamics, increased durability, and improved ball control.

Quality Control and Testing Protocols

Establishing stringent quality control and testing protocols is crucial for ensuring consistent ball quality. This involves setting up standardized procedures for manufacturing, testing, and inspection. Regular quality audits should be conducted to identify any deviations from the desired specifications, allowing for immediate corrective measures.

Collaboration with Sports Professionals

Involving sports professionals, such as athletes, coaches, and trainers, is invaluable for enhancing ball quality. Their firsthand experience and feedback can provide valuable insights into the performance of different balls. Collaborating with these experts allows manufacturers to refine and tailor their products to meet the specific needs and demands of athletes.

Continuous Improvement Implementation

Continuous improvement processes, such as Lean or Six Sigma methodologies, can be applied to enhance ball quality. These frameworks involve identifying inefficiencies, eliminating waste, and implementing systemic changes to achieve optimal results. Regular reviews and feedback loops ensure ongoing enhancements and address emerging challenges.

Quality Assurance and Customer Satisfaction

Once the ball quality has been enhanced, it is crucial to maintain consistent quality assurance practices. This involves conducting regular inspections, monitoring customer feedback, and addressing any reported issues promptly. By prioritizing customer satisfaction, manufacturers can ensure that their improved ball quality meets or exceeds expectations.

How to Continuously Improve Ball Quality:

1. Regularly assess and analyze existing ball quality issues.

2. Invest in research and development to explore new materials and design features.

3. Implement stringent quality control and testing protocols.

4. Collaborate with sports professionals to gain insights and feedback.

5. Adopt continuous improvement methodologies like Lean or Six Sigma.

6. Ensure ongoing quality assurance and address customer feedback promptly.

Frequently Asked Questions

1. What is Continuous Improvement: Enhancing Ball Quality?

Continuous Improvement: Enhancing Ball Quality is a process aimed at consistently improving the quality of balls through various measures and techniques.

2. Why is Continuous Improvement important for ball quality?

Continuous Improvement ensures that balls meet the highest standards of quality, resulting in better performance, durability, and customer satisfaction.

3. What are the key benefits of Continuous Improvement in ball quality?

Continuous Improvement enhances ball performance, increases longevity, reduces defects, improves customer trust, and maintains a competitive edge in the market.

4. How can continuous improvement be achieved in ball manufacturing?

Continuous Improvement in ball manufacturing can be achieved by constantly evaluating production processes, implementing new technologies, gathering customer feedback, and fostering a culture of innovation and learning.

5. What role does quality control play in Continuous Improvement?

Quality control ensures that the manufacturing process meets predetermined standards and identifies areas for improvement, contributing to the overall Continuous Improvement efforts.

6. How can data analysis contribute to Continuous Improvement in ball quality?

Data analysis provides insights into factors affecting ball quality, allows for identifying trends and patterns, and helps in making informed decisions to drive Continuous Improvement initiatives.

7. What are some common challenges in implementing Continuous Improvement for ball quality?

Common challenges in implementing Continuous Improvement include resistance to change, lack of resources, inadequate training, and difficulties in aligning the entire organization towards the improvement goals.

8. How often should Continuous Improvement initiatives be conducted?

Continuous Improvement initiatives should be conducted regularly, ideally on an ongoing basis, to ensure sustained enhancements in ball quality and to stay ahead of competitors.

9. Can Continuous Improvement only be applied to ball manufacturing?

No, Continuous Improvement can be applied to any industry or process, including ball manufacturing. The principles and methodologies of Continuous Improvement are versatile and can be adapted to various contexts.

10. How can stakeholders contribute to Continuous Improvement in ball quality?

Stakeholders, including manufacturers, employees, suppliers, and customers, can contribute to Continuous Improvement by actively participating in feedback systems, suggesting improvements, embracing a culture of quality, and advocating for necessary changes.

Final Thoughts

Continuous Improvement plays a crucial role in enhancing ball quality and optimizing production processes. By adopting a mindset focused on improvement and leveraging data-driven insights, manufacturers can achieve superior ball performance, customer satisfaction, and stay competitive in the ever-evolving market.

Embracing Continuous Improvement as an ongoing practice ensures that ball quality remains a priority, leading to better products, increased customer loyalty, and continued growth for the industry. With each iteration, the potential for innovation and advancement in ball manufacturing becomes limitless.