Automation: Streamlining Ball Fabrication

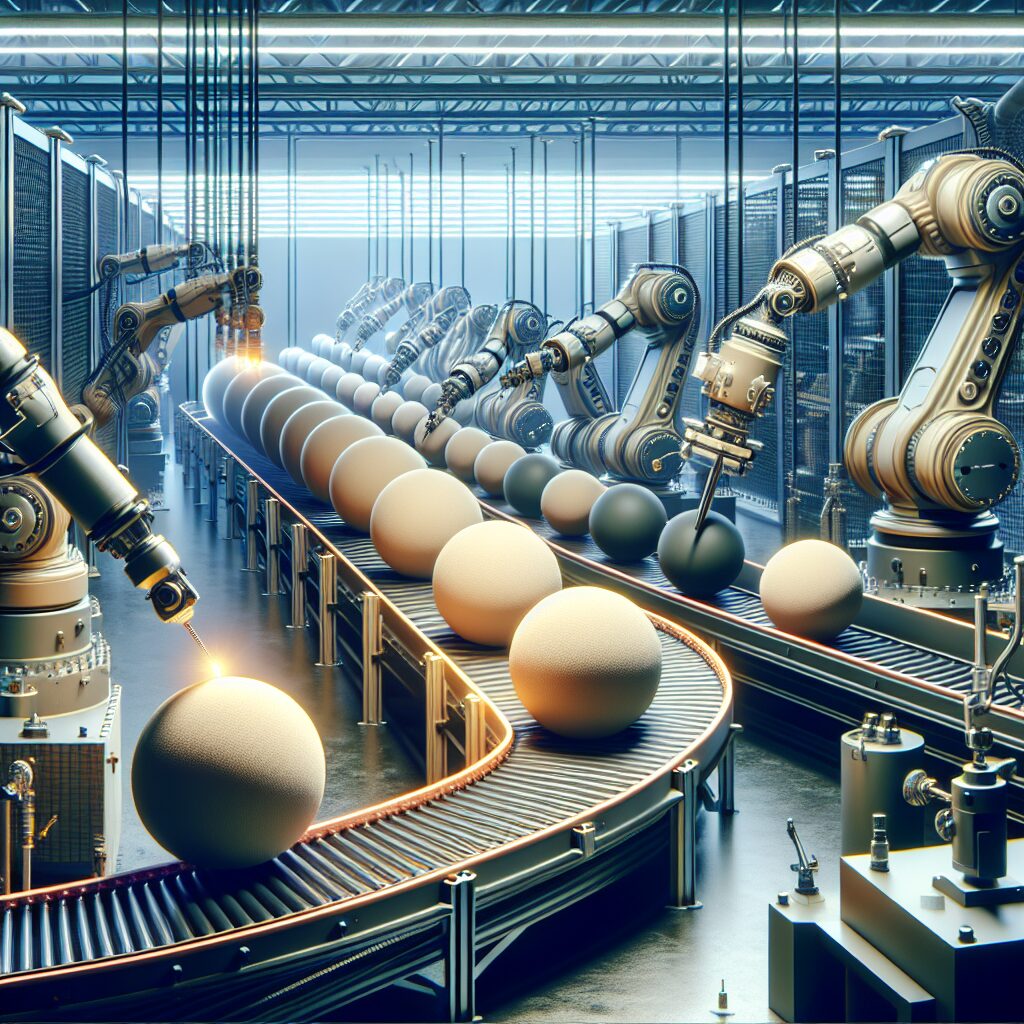

In the fast-paced world of manufacturing, automation has emerged as a game-changer, revolutionizing the way various industries operate and achieve their production goals. The process of automation involves the use of computerized systems and robotics to perform tasks that were previously carried out manually. When it comes to the fabrication of balls, whether it’s for sporting events or industrial purposes, automation has proven to be an indispensable tool. By leveraging cutting-edge technology, manufacturers can streamline the ball fabrication process, enhancing efficiency, precision, and overall productivity.

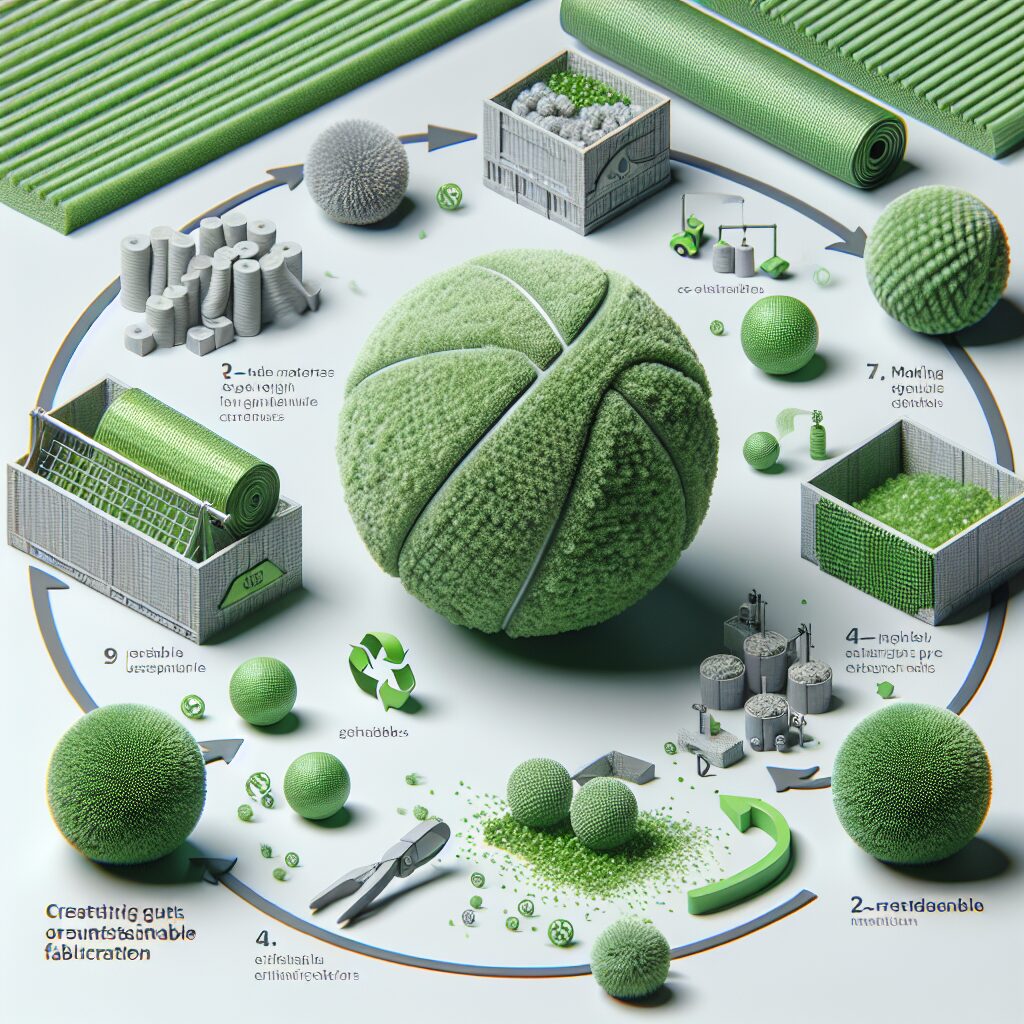

One unique insight related to automation in ball fabrication is its ability to ensure consistency and uniformity in the production process. Manual manufacturing methods often result in slight variations in size, weight, and quality across different batches. However, by employing automated systems, manufacturers can eliminate human error and achieve unparalleled precision. The use of robotics enables precise measurements and calculations, ensuring that each ball meets the desired specifications. Moreover, automation significantly reduces waste and enhances the overall quality control process, as faulty or non-compliant balls can be swiftly identified and eliminated from the production line.

Moving forward, this article will delve into the key takeaways of automation in ball fabrication. We will explore the impact of automation on production efficiency and cost-effectiveness, as well as its role in meeting the ever-growing demand for high-quality balls. Additionally, we will discuss how automation empowers manufacturers to customize and innovate within the boundaries of standardized fabrication processes. Join us as we unravel the fascinating world of automation and its transformative effects on the ball manufacturing industry.

Key Takeaways

1. Automation is revolutionizing ball fabrication by increasing efficiency and reducing costs through the use of advanced technologies and robotics.

2. The integration of automated systems allows for precise and consistent manufacturing processes, resulting in high-quality balls that meet strict industry standards.

3. Automation also improves worker safety by reducing the need for manual labor and handling of heavy machinery, minimizing the risk of accidents and injuries.

4. The implementation of automation in ball fabrication enables companies to meet the growing demand for balls in various sectors, such as sports, automotive, and aerospace, while ensuring faster production cycles.

5. While there may be concerns about job displacement, the adoption of automation in ball fabrication creates new opportunities for skilled workers to operate and maintain the sophisticated machinery, leading to a more advanced and specialized workforce in the industry.

How Does Automation Streamline Ball Fabrication?

The Role of Automation in Ball Fabrication

Automation has revolutionized the ball fabrication industry, providing lucrative benefits for manufacturers. By implementing automated systems, companies can streamline their production processes, optimize efficiency, and enhance the overall quality of ball fabrication.

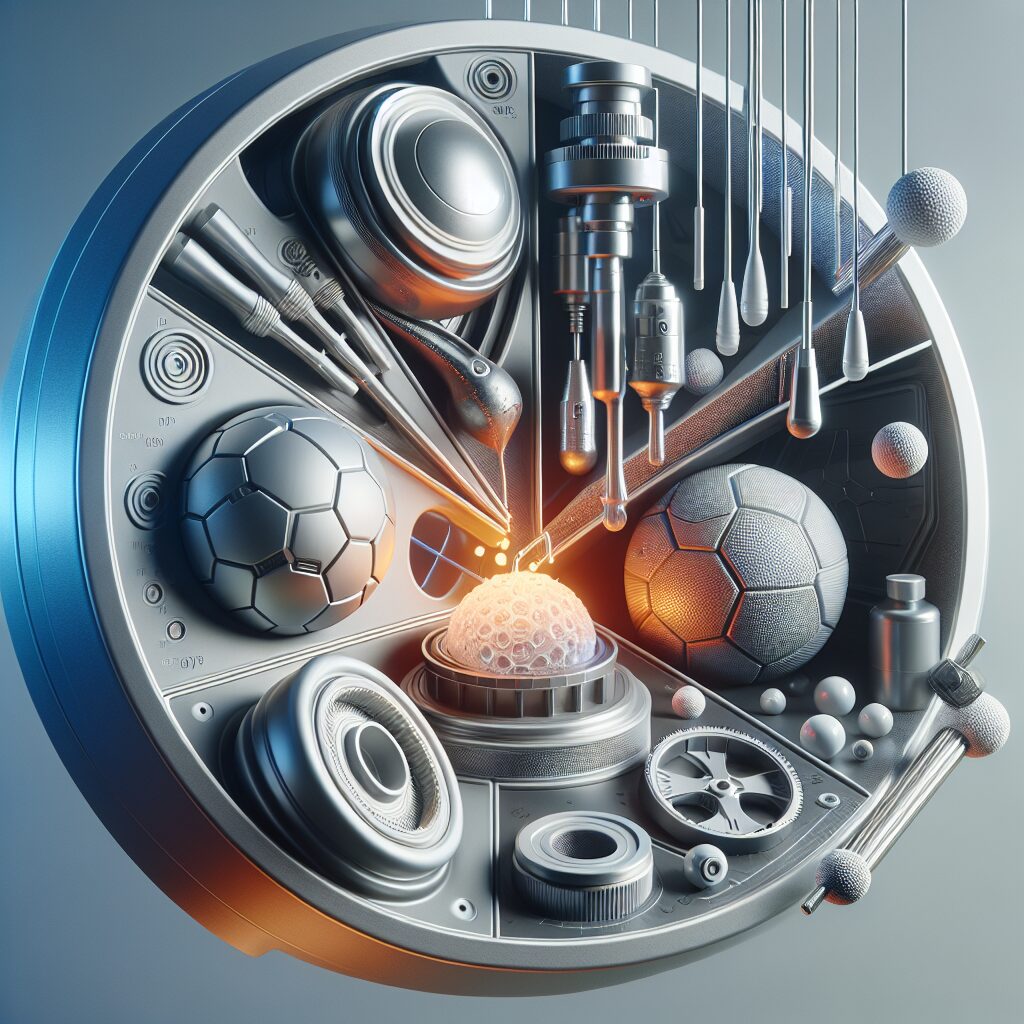

Automated Machining and Production

One of the key aspects of automation in ball fabrication is automated machining and production. Automated machines carry out various manufacturing processes, including cutting, shaping, and polishing the balls. These machines are programmed to perform accurate and precise movements, resulting in consistent quality and improved productivity.

Quality Control through Automation

Automation enables enhanced quality control in ball fabrication. Through automated inspection systems, manufacturers can ensure the uniformity and integrity of the balls being produced. These systems use advanced technologies such as cameras, sensors, and algorithms to detect any imperfections or deviations, minimizing errors and maximizing the overall quality.

Efficiency and Cost Savings

Implementing automation in ball fabrication leads to increased efficiency and significant cost savings. Automated systems can operate continuously without fatigue or breaks, allowing for continuous production cycles. Moreover, automation reduces the need for manual labor, leading to reduced labor costs and increased productivity for manufacturers.

Integration of Robotics in Ball Fabrication

Robotic systems play a crucial role in streamlining ball fabrication processes. They can handle multiple tasks simultaneously, providing faster and more efficient production cycles. Robots are adept at handling delicate materials and can perform tasks with a high level of precision. Their integration further enhances the overall efficiency and productivity of the fabrication process.

Advancements in Artificial Intelligence

Artificial Intelligence (AI) technologies have also contributed to the automation of ball fabrication. AI algorithms can analyze complex data sets, optimize production parameters, and predict maintenance or quality issues. By leveraging AI, manufacturers can improve process control, minimize downtime, and reduce material waste, ultimately leading to better overall outcomes.

Ensuring Safety in Automated Ball Fabrication

While automation offers numerous advantages, it is essential to prioritize safety in ball fabrication. Proper training, maintenance protocols, and safety measures should be implemented to ensure the well-being of workers and prevent accidents. Regular inspections and adherence to safety standards are crucial in creating a secure working environment.

Guide to Implement Automation in Ball Fabrication:

- Assess current production processes and identify areas suitable for automation.

- Research and select appropriate automated systems and machinery.

- Ensure compatibility and integration of new systems with existing infrastructure.

- Train employees on operating and maintaining automated machinery.

- Implement quality control measures and monitor performance regularly.

- Continuously optimize and upgrade automation systems to stay ahead.

Frequently Asked Questions

1. What is Automation: Streamlining Ball Fabrication?

Automation: Streamlining Ball Fabrication refers to the process of using automated machines and systems to efficiently manufacture balls, such as those used in sports or industrial applications. It involves employing technology to streamline the production process, enhance accuracy, and increase productivity.

2. What are the benefits of automating ball fabrication?

Automating ball fabrication offers several advantages. It reduces labor costs and human error, improves production speed, and ensures consistent quality. Additionally, automation enables customization and flexibility in the manufacturing process, allowing for the creation of unique ball designs tailored to specific needs.

3. How does automation improve productivity in ball fabrication?

Automation significantly improves productivity in ball fabrication by eliminating manual tasks that are time-consuming and prone to errors. By automating processes such as material cutting, shaping, and polishing, manufacturers can produce a higher quantity of balls in a shorter time frame, leading to increased output.

4. Can automation enhance the accuracy of ball fabrication?

Absolutely! Automation plays a crucial role in enhancing the accuracy of ball fabrication. Automated machines are programmed to perform precise measurements, cuts, and finishes, ensuring consistent dimensions and surface qualities. This accuracy is essential for maintaining the desired performance characteristics and meeting industry standards.

5. Are there any cost savings associated with automating ball fabrication?

Yes, automating ball fabrication can result in considerable cost savings. Although initial investment costs in automation technology may be higher, the long-term benefits outweigh them. Labor costs are reduced as fewer workers are required in the production process, and the minimized risk of errors reduces costs associated with rework and waste materials.

6. Can automation in ball fabrication lead to job losses?

While automation may change job roles and requirements in the ball fabrication industry, it does not necessarily lead to widespread job losses. The adoption of automation often requires skilled operators and technicians to operate and maintain the automated systems. Furthermore, automation can create new job opportunities in areas such as programming, system maintenance, and quality control.

7. Does automation allow for customization in ball fabrication?

Yes, automation enables customization in ball fabrication. Advanced automated machines can be programmed to produce balls with specific characteristics, sizes, and designs. This flexibility allows manufacturers to cater to diverse customer needs and offer personalized solutions, which can be beneficial in various industries, including sports and automotive.

8. What challenges may arise when implementing automation in ball fabrication?

Implementing automation in ball fabrication may face challenges such as initial setup costs, training employees to operate automated systems, and integrating new technology with existing production processes. Additionally, continuous technological advancements may require periodic updates or upgrades to keep up with industry standards.

9. Can small-scale ball manufacturers benefit from automation?

Absolutely! Automation can benefit small-scale ball manufacturers just as it does larger companies. While the initial investment may be a consideration, small-scale manufacturers can benefit from increased productivity, improved quality control, and reduced labor costs that automation offers. It allows them to compete on a more level playing field with larger competitors.

10. What is the future of automation in ball fabrication?

The future of automation in ball fabrication is promising. As technology continues to evolve, we can expect even more advanced automated systems capable of handling complex manufacturing processes with greater efficiency and precision. Integration with artificial intelligence and machine learning may further enhance productivity and customization capabilities in ball fabrication.

Final Thoughts

In conclusion, automation has revolutionized the ball fabrication industry, enabling manufacturers to streamline their processes, improve productivity, and deliver high-quality products. The benefits of automation, including cost savings, accuracy, and customization, make it an indispensable tool for both large-scale and small-scale ball manufacturers.

As we look ahead, it is evident that automation will continue to play a vital role in shaping the future of ball fabrication. Advancements in technology will drive further innovation, opening up new possibilities for customized designs and meeting evolving market demands. Embracing automation is not just a trend but a necessity to stay competitive in the ever-changing world of ball manufacturing.