The Ever-Changing Materials in Ball Design refer to the continuous advancements and innovations in the materials used for manufacturing sports balls. From soccer balls to golf balls, manufacturers are constantly exploring new materials that can enhance performance, durability, and overall playing experience. One unique insight related to this topic is the significant influence that material choice has on the behavior and characteristics of the ball during gameplay. The right materials can significantly impact how the ball moves, bounces, and even how it interacts with different surfaces.

With the advent of technology and research, the world of sports balls has witnessed some remarkable developments in recent years. Manufacturers are now experimenting with materials such as thermoplastics, microfibers, and hybrid constructions to achieve optimal performance. These newer materials offer improved durability, better aerodynamics, and enhanced control. For instance, in golf ball design, using advanced materials like urethane covers or hybrid layering techniques allows for greater spin control, accuracy, and distance.

Moving forward, let’s dive deeper into the key takeaways of the ever-changing materials in ball design. We will explore how the choice of materials impacts various sports balls, the unique features that different materials bring to the table, and the future possibilities for ball design. So, keep reading to discover fascinating insights into this evolving arena of sports equipment manufacturing.

Key Takeaways

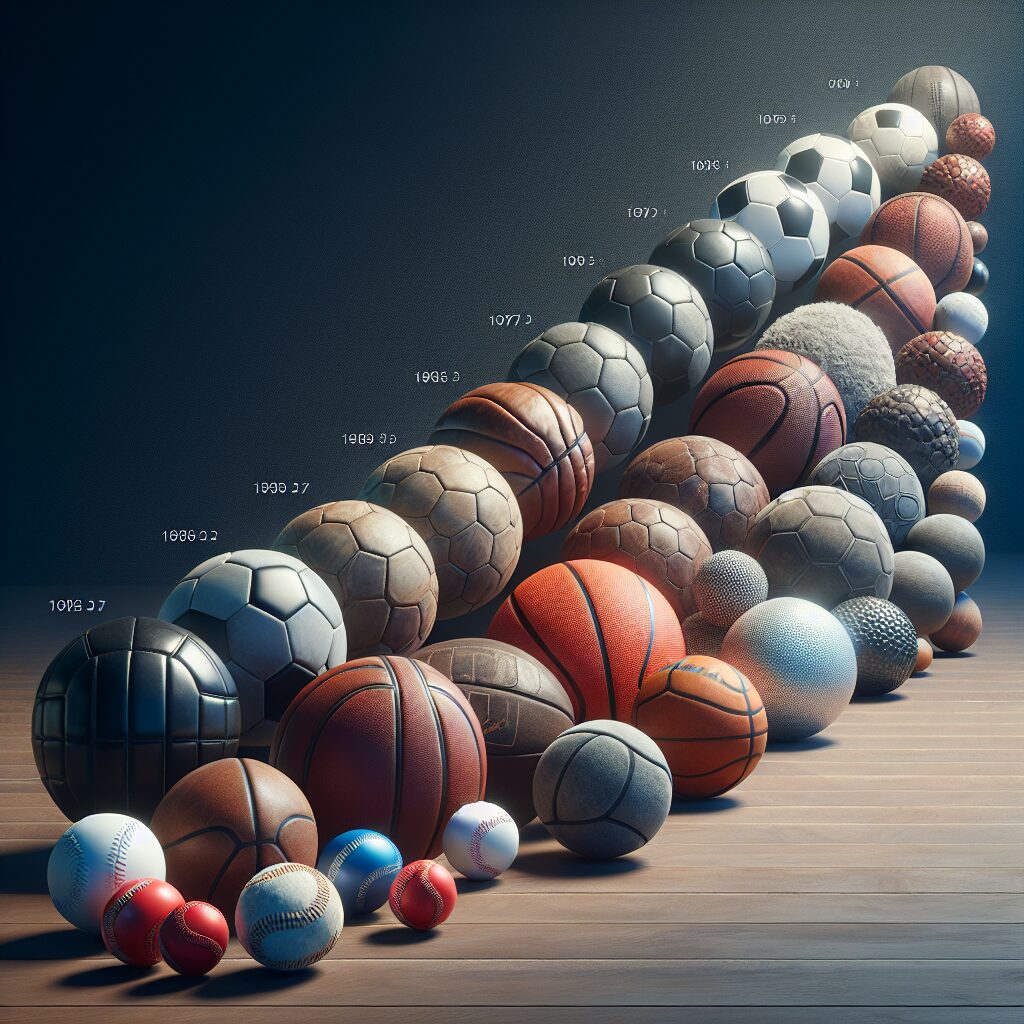

1. Ball design has evolved significantly over the years, with materials playing a crucial role in enhancing performance and meeting diverse player preferences.

2. Core materials, such as rubber and synthetic compounds, impact the ball’s speed, spin, and bounce. Technological advancements have led to the development of dynamic cores that offer superior performance and consistency.

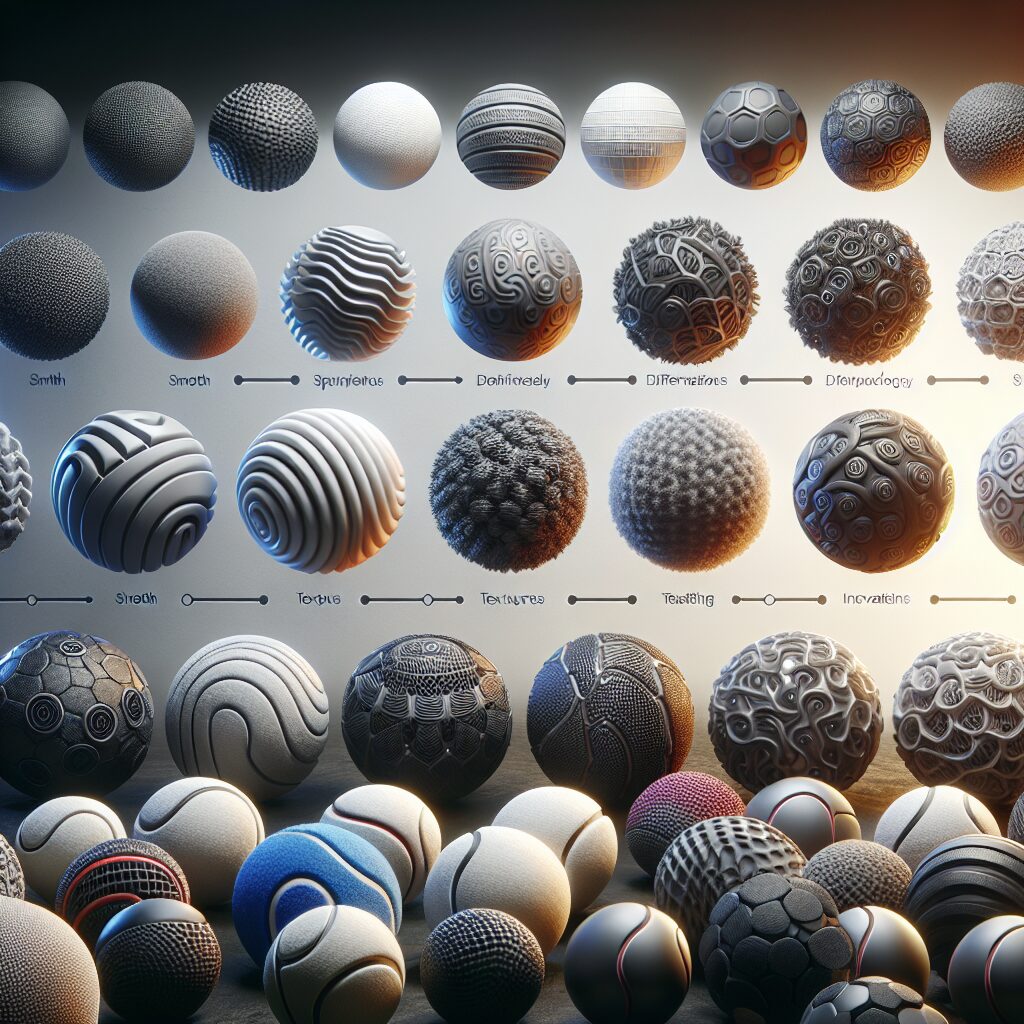

3. The cover materials used in ball design, including leather, synthetic materials, and thermoplastics, determine factors like durability, grip, and responsiveness. Innovative multi-layered covers have been introduced to provide enhanced performance and player satisfaction.

4. The construction of the ball, including the number and arrangement of panels, affects its flight characteristics and control. Traditional hand-stitched panels are being replaced by thermally bonded or machine-stitched designs for improved precision and durability.

5. Ongoing research and development of new materials, in collaboration with players, ensure continuous improvements in ball design. Players’ feedback helps manufacturers create balls that deliver optimum performance, while also considering environmental sustainability.

What are the Latest Advancements in Ball Design Materials?

Introduction

In the world of ball design, materials play a crucial role in ensuring optimal performance and durability. With advancements in technology and engineering, materials used in ball design have been continuously evolving. Understanding the ever-changing materials in ball design is essential for athletes, manufacturers, and enthusiasts alike.

Rubber

Rubber has been a popular material used in ball design for many years. It offers excellent grip, bounce, and durability. However, advancements in rubber technology have led to the introduction of specialized rubbers that enhance specific performance attributes. For instance, high-performance basketballs now utilize a composite rubber that provides superior grip and bounce.

Leather

Leather has long been associated with traditional ball designs, particularly in sports like football and baseball. The quality and characteristics of leather can greatly influence the ball’s performance. With advancements in tanning and processing techniques, manufacturers have been able to produce more durable and water-resistant leather balls. Synthetic leather alternatives have also emerged, offering greater consistency and lower costs.

Synthetic Materials

The use of synthetic materials in ball design has gained popularity due to their versatility and cost-effectiveness. Materials such as polyurethane, polyvinyl chloride (PVC), and polyethylene provide manufacturers with the ability to customize ball properties to suit different sports and playing conditions. These materials offer improved durability, weather resistance, and control over performance characteristics.

Composite Materials

Composite materials combine the best attributes of different materials to create balls with enhanced performance. By layering various materials, such as rubber, synthetic fibers, and foams, manufacturers can fine-tune properties like grip, bounce, and flight stability. Composite materials are commonly used in high-end golf balls, tennis balls, and cricket balls.

Smart Materials

The field of ball design has also seen the integration of smart materials that can adapt and respond to external stimuli. For example, in basketballs, sensors embedded in the ball can provide real-time data on velocity, spin, and shooting accuracy. These advancements allow athletes and coaches to analyze their performance in unprecedented detail.

Numbered Guides for Ball Design Materials

- Consider the specific sport or application: Different sports require different ball properties and materials. Analyze the demands of the game to determine the ideal materials for optimal performance.

- Stay up-to-date with advancements: The field of ball design is constantly evolving. Keep an eye on new materials, manufacturing techniques, and research to stay ahead of the curve.

- Test and evaluate materials: Before mass production, thoroughly test and evaluate different materials to ensure they meet the desired performance standards. Factors such as grip, bounce, durability, and environmental impact should be considered.

- Consult experts: Seek advice from material scientists, engineers, and sports professionals to gain insights into the latest advancements and best practices in ball design materials.

- Consider cost-efficiency: While performance is crucial, it is also essential to consider the cost-effectiveness of materials. Evaluate the balance between performance and production costs to ensure a successful and sustainable product.

FAQs about The Ever-Changing Materials in Ball Design

1. What is the significance of materials in ball design?

Materials play a crucial role in ball design as they determine factors such as performance, durability, and feel. Choosing the right materials can greatly impact the performance and effectiveness of the ball in different sports.

2. How do the materials used in ball design affect performance?

The materials used in ball design can affect performance in various ways. For example, using a lightweight material can enhance speed and agility, while a material with high bounce properties can improve rebound. The choice of materials can also affect the aerodynamics and grip of the ball.

3. Are there any specific materials that are commonly used in ball design?

Yes, there are several commonly used materials in ball design. These include synthetic leather, rubber, PVC, polyurethane, and various kinds of foam. The selection of materials depends on the specific requirements of the sport and the desired performance characteristics.

4. How do new materials impact the development of ball design?

New materials open up opportunities for innovation and advancements in ball design. They allow manufacturers to create balls with improved performance, enhanced durability, and better overall playing experience. New materials also enable the development of specialized balls for specific sports or playing conditions.

5. Are environmentally friendly materials being used in ball design?

Yes, there is a growing trend towards using environmentally friendly materials in ball design. Manufacturers are increasingly opting for sustainable and recyclable materials that minimize negative environmental impact. This shift aligns with the global focus on sustainability and responsible production.

6. How does the choice of materials affect the lifespan of a ball?

The choice of materials significantly affects the lifespan of a ball. High-quality materials that are durable and resistant to wear can prolong the lifespan of a ball, allowing it to withstand prolonged and intense use. On the other hand, using lower quality or less durable materials may result in a shorter lifespan for the ball.

7. Can the choice of materials impact ball safety?

Indeed, the choice of materials can impact ball safety. Certain materials may increase the risk of injuries, such as those with poor grip properties or excessive hardness. Manufacturers need to prioritize the selection of materials that ensure player safety without compromising performance.

8. How often do materials in ball design change?

The materials used in ball design are subject to constant evolution and improvement. As new technologies and materials become available, manufacturers strive to incorporate them into their designs to enhance performance and meet changing demands. The frequency of material changes depends on advancements in material science and industry trends.

9. Are there any regulations or standards in place for ball materials?

Yes, there are regulations and standards in place for ball materials. Sports governing bodies, such as FIFA for soccer or the NBA for basketball, often set guidelines regarding the permissible materials for official games. These regulations ensure fair competition, player safety, and consistent ball characteristics across different games and events.

10. How can consumers determine the best materials for their desired ball?

Consumers can determine the best materials for their desired ball by considering factors such as the sport they are playing, the desired characteristics of the ball (e.g., grip, responsiveness), and their personal preferences. It can also be helpful to read product reviews and consult with experts or experienced players to make an informed decision.

Final Thoughts on The Ever-Changing Materials in Ball Design

As technology advances and new materials emerge, the field of ball design continues to evolve at a rapid pace. The choice of materials has a profound impact on the performance, durability, and safety of balls used in various sports. Manufacturers constantly strive to push the boundaries by experimenting with innovative materials to optimize ball characteristics and enhance the overall playing experience.

Furthermore, the increasing focus on sustainability and environmental consciousness has prompted the industry to explore eco-friendly materials that are both functional and environmentally responsible. This emphasis on using materials with minimal ecological footprint showcases the commitment of manufacturers towards a more sustainable future.