Advancements in Ball Durability: Designing for Longevity

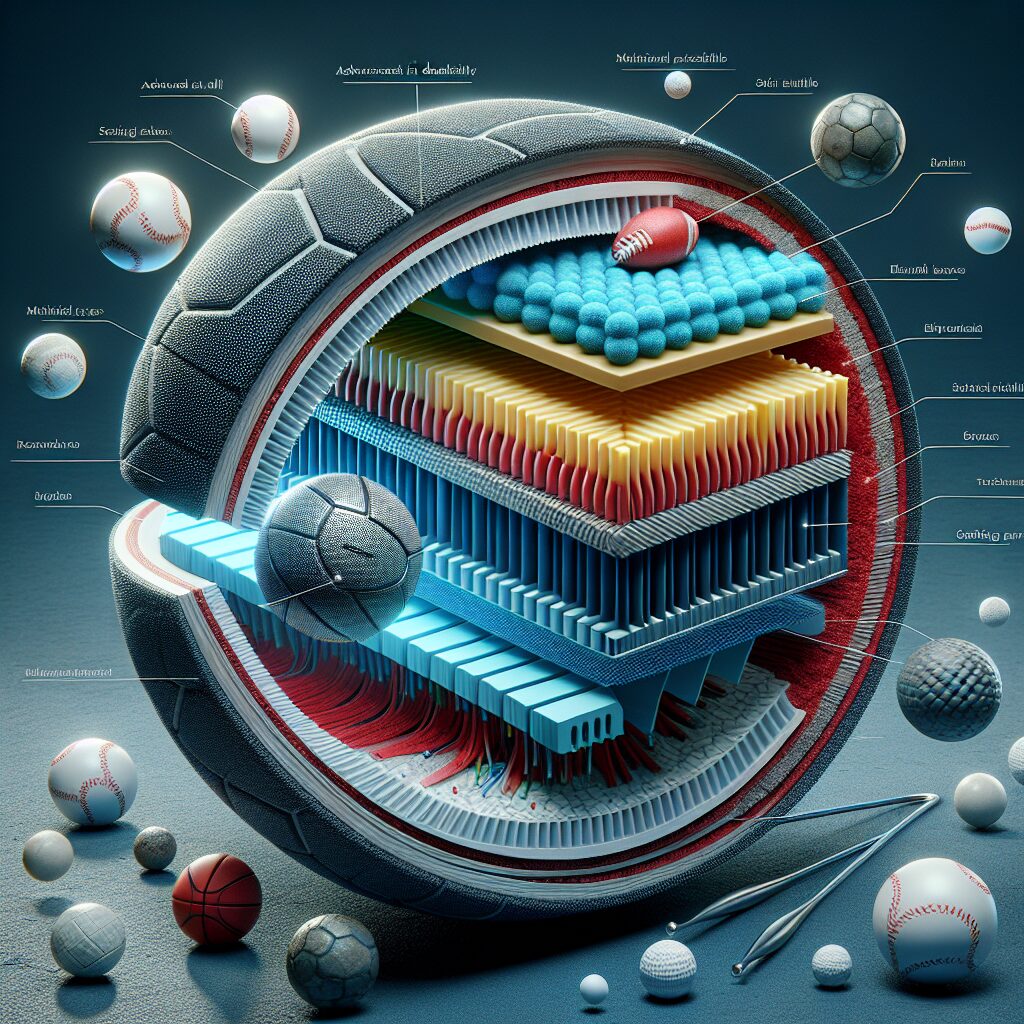

In the world of sports, the durability of balls is of paramount importance. Whether it is a soccer ball being kicked across the field or a baseball being thrown with lightning speed, the ability to withstand intense impact and maintain its shape is crucial. As technology advances, so does the innovation in designing balls for long-lasting performance. One unique insight into this topic is the significant role that material composition plays in enhancing ball durability. With advancements in material science, manufacturers are now able to create balls using composite materials that are not only lightweight but also exhibit exceptional strength. This allows the ball to withstand the rigors of the game, minimizing the risk of damage or deformation.

Another impactful aspect in ball durability is the design of the ball’s outer surface. Manufacturers understand that a smooth, seamless exterior can significantly contribute to the ball’s longevity. Through meticulous research and testing, engineers have developed special coatings and linings that protect the ball from wear and tear, such as abrasion or punctures. These advancements in surface technology not only enhance the overall performance but also prolong the lifespan of the ball.

Moving forward, we will delve into the key takeaways regarding advancements in ball durability. We will discuss the various materials used in ball manufacturing that contribute to longevity, as well as explore the importance of surface design and technology in ensuring the durability of balls. Furthermore, we will examine how these advancements impact specific sports, from soccer to basketball, and how they are transforming the game. So, stay tuned to discover the fascinating world of designing balls for longevity and the ways it revolutionizes sports!

Key Takeaways

1. Manufacturers are developing new materials and construction techniques to improve the durability of balls, focusing on reducing wear and tear during normal use and increasing their lifespan.

2. The design of the ball’s outer cover is critical for durability, with new materials like synthetic leather and improved stitching techniques being used to resist abrasion and withstand intense impact.

3. Advances in bladder technology are enhancing the ball’s air retention capabilities, ensuring a consistent feel and performance over a longer period of time.

4. Testing protocols have been implemented to measure a ball’s durability, including simulations of real game scenarios and thorough examinations of the ball’s performance after prolonged use.

5. By prioritizing durability, manufacturers aim to reduce the environmental impact of ball production and disposal, as well as provide consumers with longer-lasting products that offer better value for money.

How Can Designing for Longevity Advance Ball Durability?

1. Material Selection

Choosing the right materials is crucial when designing a durable ball. Manufacturers are constantly experimenting with new materials that can withstand high impact and pressure. For example, the use of reinforced polymers, such as carbon fiber, has proven to enhance the durability of balls used in various sports. Additionally, advancements in synthetic leather have allowed for increased resistance to abrasion and tearing, making balls last longer.

2. Structural Enhancements

Advancements in ball durability also involve improving the structural integrity of the ball. By optimizing the design and construction, manufacturers can create balls that are more resistant to deformation and maintain their shape even after intense use. Reinforced inner structures, such as laminated layers or specialized bladder systems, help distribute impact forces and prevent excessive wear and tear.

3. Seam Technology

The seams of a ball are often vulnerable areas prone to splitting or unraveling. Modern ball designs focus on strengthening these seams to increase durability. Seamless or bonded constructions are becoming popular as they eliminate traditional stitched seams, reducing the risk of damage over time. Additionally, advanced stitching techniques, including reinforced threads and precision sewing, improve the overall strength and longevity of the ball.

4. Surface Coatings

Protective coatings play a significant role in enhancing ball durability. The application of specialized coatings can improve resistance to abrasion, moisture, and damage caused by environmental factors. Some coatings also offer anti-fungal or anti-bacterial properties to prevent degradation and maintain cleanliness. Furthermore, these coatings can enhance the grip of the ball, allowing for better control and reducing the likelihood of accidental slips and drops.

5. Testing and Quality Control

To ensure the durability of a ball, rigorous testing and quality control procedures are vital. Manufacturers subject their products to various impact, stress, and durability tests to simulate real-game conditions. These tests help identify any weaknesses in the design or materials used, allowing for necessary adjustments and improvements before reaching consumers. Advanced data analysis and feedback from athletes also contribute to refining ball design and ensuring maximum longevity.

How Can You Extend the Lifespan of Your Balls?

- Proper Storage: Store your balls in a clean and dry environment, away from extreme temperatures or direct sunlight.

- Regular Cleaning: Keep your balls clean by wiping them with a damp cloth or using mild soap and water. Avoid abrasive cleaners that can damage the ball’s surface.

- Appropriate Inflation: Maintain the correct air pressure in your ball to prevent excessive stress on the materials and maintain optimal performance.

- Avoid Sharp Objects: Keep your balls away from sharp edges or objects that could puncture or damage them.

- Rotate Usage: If you have multiple balls, rotate their usage to distribute the wear and tear evenly.

- Protective Covers: Consider using protective covers or cases when storing or transporting your balls to shield them from potential damage.

- Inspect Regularly: Periodically inspect your balls for any signs of damage, such as cracks, splits, or loose seams. If detected, address the issue promptly to prevent further deterioration.

- Follow Manufacturer Guidelines: Adhere to any specific care instructions or recommendations provided by the ball manufacturer to ensure longevity.

Frequently Asked Questions

1. How do advancements in ball durability impact the game?

Advancements in ball durability have a significant impact on the game as they ensure a longer lifespan for the ball, reducing the frequency of replacements. This not only saves costs for teams and players but also improves overall gameplay by providing consistent performance throughout matches.

2. What are the key factors considered when designing for ball longevity?

Designing for ball longevity requires considering various factors such as the quality of materials used, the construction techniques employed, and the level of testing performed. Manufacturers also focus on creating ball surfaces that can withstand intense play and varying weather conditions.

3. Can advancements in ball durability make them suitable for multiple playing surfaces?

Yes, advancements in ball durability are aimed at making them suitable for multiple playing surfaces. By incorporating stronger materials and innovative design techniques, manufacturers strive to create balls that can perform exceptionally well on both turf and grass surfaces.

4. How do improvements in ball durability benefit players?

Improvements in ball durability benefit players by offering a more reliable and consistent ball performance. It reduces the risk of unpredictable bounces and wear and tear during gameplay, allowing players to focus on their skills without worrying about ball integrity.

5. Are balls designed for longevity still comfortable to play with?

Yes, while the focus is on durability, balls designed for longevity are also engineered to provide optimal comfort during gameplay. The materials used ensure a soft touch and good grip, allowing players to have a comfortable and responsive experience on the field.

6. What testing methods are commonly employed to determine ball durability?

Commonly employed testing methods to determine ball durability include subjecting the ball to simulated game conditions, including repetitive kicks, bounces, and impacts. Additionally, manufacturers may conduct stress tests to evaluate the ball’s ability to withstand high pressures and intense play.

7. Can advancements in ball durability reduce injuries during matches?

While advancements in ball durability primarily focus on enhancing performance and longevity, they indirectly contribute to reducing injuries during matches. With more durable balls, the chances of unexpected bursts or deformations that may cause accidents are minimized, ensuring a safer playing environment.

8. Do advancements in ball durability affect the aesthetics of the ball?

No, advancements in ball durability do not necessarily affect the aesthetics of the ball. Manufacturers strive to maintain the visual appeal of the ball while incorporating advanced materials and construction techniques to enhance durability. The focus is on preserving the traditional look while improving performance.

9. Are balls designed for longevity suitable for professional matches?

Yes, balls designed for longevity are suitable for professional matches. In fact, durability is a crucial requirement for balls used in professional leagues and tournaments to ensure consistent performance and reduce the need for ball changes during crucial moments of play.

10. Can advancements in ball durability impact the environmental footprint of the game?

Yes, advancements in ball durability can positively impact the environmental footprint of the game. By reducing the frequency of ball replacements, less waste is generated. Additionally, manufacturers are increasingly focusing on using sustainable materials and eco-friendly production processes, further minimizing the game’s environmental impact.

Final Thoughts

Advancements in ball durability and designing for longevity have revolutionized the game by providing players with high-quality balls that stand the test of time. The evolution of materials, design techniques, and testing methods have resulted in improved performance and reduced costs for both professionals and enthusiasts.

As technology progresses, the future of ball durability looks promising. Manufacturers continue to explore innovative ways to enhance the lifespan of balls while maintaining their playability and visual appeal. By focusing on sustainability and environmentally friendly practices, the game can continue to evolve without compromising the integrity of the sport or the planet.