Testing Procedures: The Path to High-Quality Balls

In the realm of manufacturing and production, the importance of rigorous testing procedures cannot be overstated. When it comes to the creation of high-quality balls, such procedures are absolutely essential. What may seem like a seemingly simple object holds a multitude of complexities when it comes to its functionality and performance. Therefore, testing procedures play a significant role in ensuring that these balls meet the highest standards of quality and consistency.

One unique fact that underscores the significance of testing procedures is that the performance of a ball can vary greatly depending on its design, material, and construction. Whether it is a basketball, soccer ball, or golf ball, each type requires specific testing procedures to assess its bounce, durability, spin, and other essential characteristics. These tests provide valuable insights into the ball’s performance, enabling manufacturers to refine their designs and make necessary adjustments to ensure optimal functionality.

Moving forward, this article will delve into key takeaways regarding testing procedures for high-quality balls. We will explore the various types of tests used in the industry to evaluate different aspects of ball performance. Additionally, we will discuss the impact of these testing procedures on the overall quality of balls, and how they contribute to enhancing the experience of athletes and sports enthusiasts alike. By the end, readers will gain a comprehensive understanding of the importance of testing procedures in the pursuit of producing top-notch balls. Stay tuned for the upcoming insights that will shed light on this critical aspect of ball manufacturing.

Key Takeaways

1. The article discusses the importance of testing procedures in ensuring the production of high-quality balls for various sports.

2. Clear and objective test criteria, coupled with accurate measurement tools, are essential in evaluating the performance and durability of balls.

3. Testing should be comprehensive and cover multiple factors, such as weight, rebound, compression, and roundness, to ensure consistent quality across different batches.

4. Inadequate or improper testing procedures can lead to substandard balls that may affect player experience, safety, and overall game performance.

5. Collaboration between manufacturers, sports organizations, and testing facilities is crucial in developing and implementing standardized testing protocols to uphold quality standards in ball production.

Is Following Testing Procedures the Path to High-Quality Balls?

Importance of Testing Procedures for High-Quality Balls

Testing procedures play a crucial role in ensuring the production of high-quality balls. Implementing rigorous testing protocols helps manufacturers verify the performance, durability, and safety of the balls before they reach the market. This section will delve into the various aspects of testing procedures and their significance in producing top-notch balls.

Performance Testing

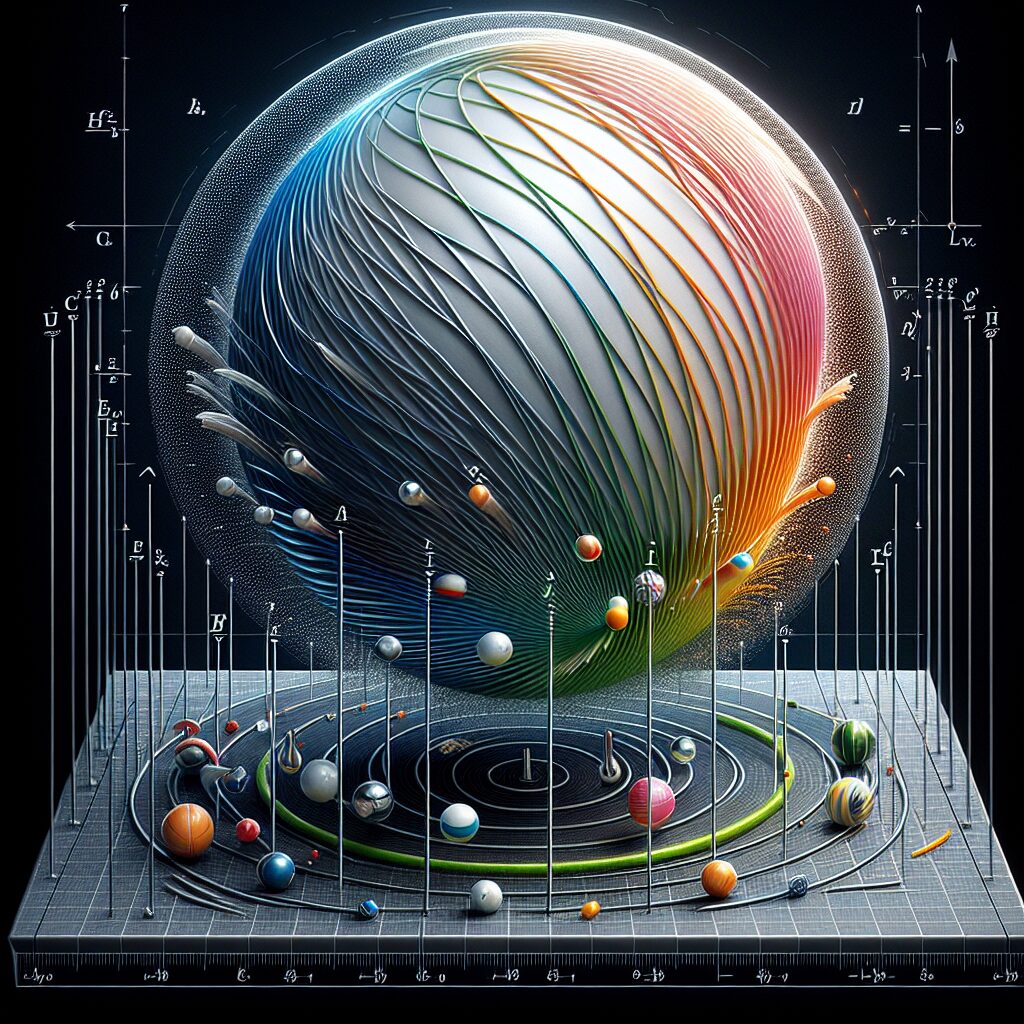

One key aspect of testing procedures is performance testing. This involves evaluating the ball’s ability to meet specific performance standards. Different sports have different requirements for their balls, such as bounce, aerodynamics, and spin. Through performance testing, manufacturers can determine if the balls meet the necessary specifications for optimal gameplay. This testing may involve factors like rebound height, compression, flight trajectory, and grip.

Durability Testing

Durability is another vital factor in determining the quality of balls. Durability testing focuses on assessing the ball’s ability to withstand rigorous use and external forces. Manufacturers subject the balls to repeated impacts, stress, and varying weather conditions to evaluate their durability. This testing helps identify any weak points or potential issues with the materials or construction, enabling manufacturers to make necessary improvements for increased longevity.

Safety Testing

Ensuring the safety of the players is of utmost importance in sports. Safety testing procedures are designed to detect any potential hazards associated with the balls. This includes evaluating factors like hardness, softness, and the absence of harmful chemicals or materials. By conducting thorough safety testing, manufacturers can eliminate potential risks and provide players with peace of mind, knowing that the balls they are using meet the necessary safety standards.

Compliance with Industry Standards

Testing procedures ensure that the balls comply with relevant industry standards and regulations. Different sports organizations, such as FIFA, NBA, or ITF, establish specific guidelines and requirements for the balls used in their respective sports. By adhering to these standards, manufacturers can guarantee that their balls meet the expectations set by the governing bodies and provide an optimal playing experience for athletes and enthusiasts alike.

The Role of Technology in Testing Procedures

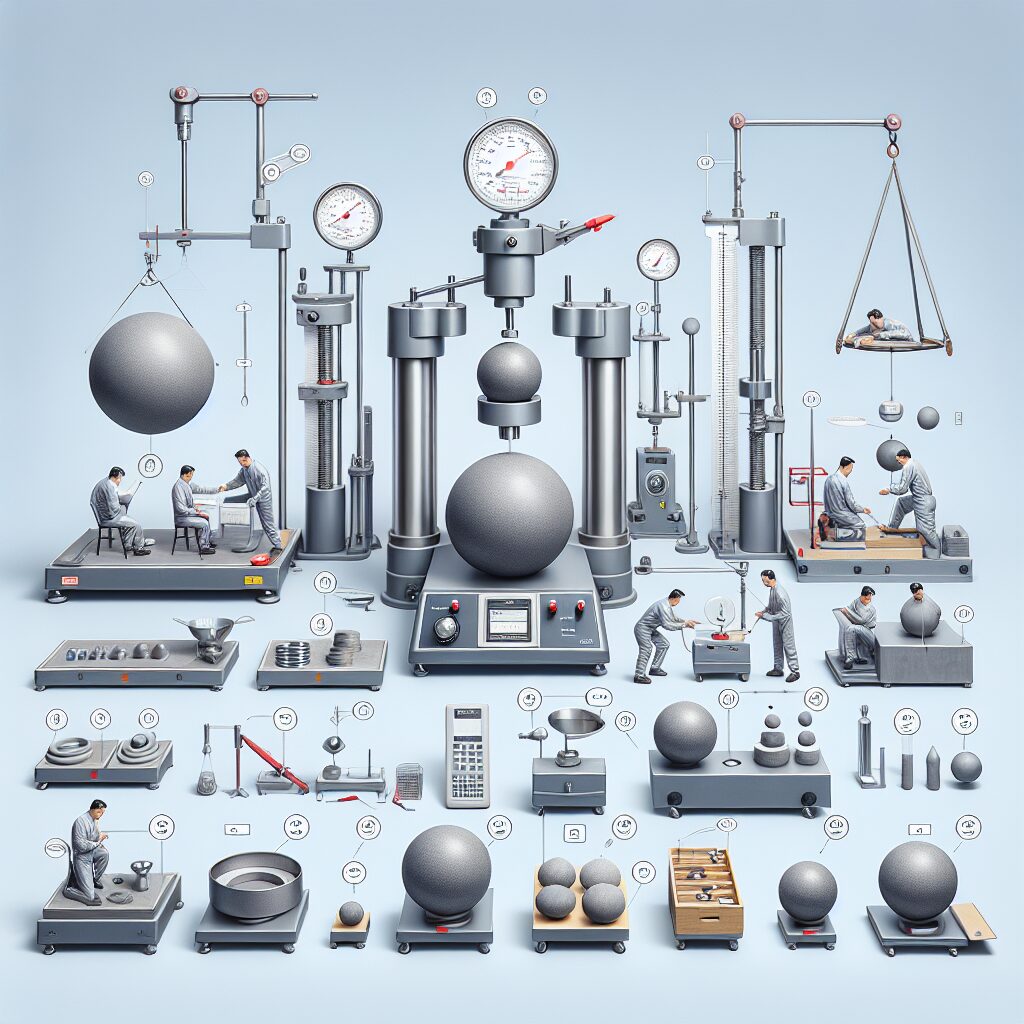

Advancements in technology have significantly enhanced testing procedures for high-quality balls. Cutting-edge equipment allows for precise measurements and analysis, leading to more accurate results. For instance, high-speed cameras can capture the ball’s trajectory, spin, and impact, providing valuable data for evaluation. Furthermore, specialized machines can simulate different gameplay scenarios to assess the balls’ performance under realistic conditions. By harnessing technology, manufacturers can refine their testing procedures and produce superior quality balls.

1. Top Tips for Implementing Effective Testing Procedures:

– Establish a comprehensive testing protocol that covers performance, durability, and safety aspects.

– Invest in modern testing equipment to ensure accurate measurements and analyses.

– Collaborate with industry experts to validate and fine-tune the testing procedures.

– Regularly update testing protocols and adapt them to changing industry standards.

– Document and track all test results systematically for future reference and analysis.

2. Does adherence to strict testing procedures guarantee high-quality balls?

– While following testing procedures is essential, it does not guarantee high-quality balls entirely.

– Other factors such as material selection, manufacturing techniques, and quality control processes also contribute to overall ball quality.

3. Can testing procedures be customized for different sports?

– Yes, testing procedures can be tailored to meet the specific requirements of different sports.

– Each sport may have unique testing parameters and standards that manufacturers need to adhere to.

4. Why should consumers prioritize balls that undergo rigorous testing procedures?

– Balls that undergo thorough testing procedures are more likely to offer superior performance, durability, and safety.

– Choosing balls that have been tested ensures a better playing experience and minimizes the risk of potential issues or hazards.

5. How can manufacturers continuously improve their testing procedures?

– Manufacturers can gather feedback from players, coaches, and experts to identify areas of improvement in their testing procedures.

– Regularly incorporating new technology and research findings into the testing process helps in enhancing its effectiveness and reliability.

Frequently Asked Questions

1. What are testing procedures for high-quality balls?

Testing procedures for high-quality balls involve a series of standardized tests to ensure their performance, durability, and adherence to quality standards. These tests can include examinations of materials, weight, size, bounce, compression, hardness, and other specific characteristics.

2. Why are testing procedures important for high-quality balls?

Testing procedures are crucial for high-quality balls because they help determine if the balls meet the required standards and specifications. This ensures that the balls perform optimally, maintain consistency, and offer a reliable experience for users, whether it’s in sports, gaming, or industrial applications.

3. Who conducts testing procedures for high-quality balls?

Testing procedures for high-quality balls are typically conducted by specialized testing laboratories or certified third-party organizations. These entities have the expertise, equipment, and facilities to perform the necessary tests and provide accurate results that can be trusted by manufacturers, distributors, and consumers.

4. How are testing procedures for high-quality balls standardized?

Testing procedures for high-quality balls are standardized through the development and implementation of industry-specific standards and protocols. Organizations such as the International Organization for Standardization (ISO) and sports governing bodies establish guidelines that define the required tests, measurement methods, acceptance criteria, and reporting formats to ensure consistency and comparability of results.

5. What are some common tests included in testing procedures for high-quality balls?

Common tests included in testing procedures for high-quality balls may include impact resistance tests, hardness tests, weight and size measurements, bounce tests, deformation tests, compression tests, and water resistance tests. The specific tests conducted depend on the intended application and industry standards.

6. How do testing procedures contribute to the safety of high-quality balls?

Testing procedures contribute to the safety of high-quality balls by identifying potential hazards or defects that could compromise the integrity of the balls. By ensuring that balls meet safety standards, the risk of accidents, injuries, or equipment failures is minimized, ensuring user safety during sports activities, recreational use, or industrial operations.

7. Can testing procedures for high-quality balls vary across different industries?

Yes, testing procedures for high-quality balls can vary across different industries. Each industry may have its own set of specific requirements and standards. For example, testing procedures for sports balls may differ from those used for industrial balls due to variations in performance expectations, materials used, and intended use.

8. How can consumers identify whether a company follows proper testing procedures for high-quality balls?

Consumers can identify whether a company follows proper testing procedures for high-quality balls by checking for relevant certifications or labels on the product packaging. Reputable manufacturers often display certifications from recognized testing organizations, ensuring that their balls have undergone rigorous testing and meet industry standards.

9. Are testing procedures a guarantee of high-quality balls?

While testing procedures significantly increase the likelihood of high-quality balls, they do not guarantee it. Testing procedures provide an objective assessment of various performance aspects, but other factors like design, materials used, and manufacturing processes also contribute to the quality of the balls. Therefore, consumers should consider a holistic approach when evaluating the overall quality of a ball.

10. Can testing procedures be customized for unique ball applications?

Yes, testing procedures can be customized for unique ball applications. Industries with specific ball requirements, such as aerospace or medical, may develop tailored testing procedures to assess the suitability of the balls for their intended applications. Customized testing helps ensure that the balls meet the specialized needs and performance demands of these industries.

Final Thoughts

The testing procedures for high-quality balls play a vital role in ensuring their reliability, performance, and safety. Manufacturers and consumers alike greatly benefit from these standardized testing protocols, as they provide an objective assessment of a ball’s quality. By adhering to established testing procedures, manufacturers can guarantee that their balls meet industry standards, instilling confidence in consumers who can make informed purchasing decisions.

Ultimately, testing procedures establish a strong foundation for the production and evaluation of high-quality balls. As technology evolves and industry standards continue to advance, it’s crucial for manufacturers, testing laboratories, and regulatory bodies to stay updated and collaborate, ensuring that testing procedures keep pace with the changing demands of diverse ball applications. Through such commitment and collaboration, the path to consistently producing exceptional high-quality balls will remain clear.