Consistency in production is a crucial factor when it comes to ensuring the quality of balls. Whether it is for sports like soccer, tennis, or baseball, or for industrial purposes like bearings or valves, maintaining consistency throughout the production process is paramount. One of the key reasons behind this is the need for precise dimensions and weights in order to achieve optimal performance. With each ball being meticulously crafted in accordance with set standards, consistency plays a pivotal role in ensuring that every ball delivers the desired performance.

A unique aspect of consistency in production is its direct impact on the durability and reliability of balls. When the manufacturing process is consistent, it helps in eliminating variations in materials, construction, and performance. This, in turn, increases the final product’s ability to withstand wear and tear, providing a longer lifespan for the ball. Furthermore, consistent production also ensures that the balls exhibit predictable behavior, enabling athletes to rely on their performance without any surprises.

Moving forward, let’s delve into the key takeaways of this article. We will explore the importance of strict quality control measures, the role of automated production processes, and the significance of using standardized materials to achieve consistency in ball production. By understanding these key aspects, manufacturers can enhance the quality of their balls and meet the expectations of athletes and consumers alike. So, without further ado, let’s dive into the details and uncover the secrets behind achieving consistency in the production of high-quality balls.

Key Takeaways

1. Consistency in production is crucial for ensuring quality balls, as slight variations in manufacturing can greatly impact the performance and durability of the product.

2. Using standardized processes and equipment throughout the production cycle helps to maintain consistency, reducing the potential for defects and inconsistencies in the final product.

3. Quality control measures, such as regular inspections and testing, are essential in ensuring that all balls meet the required standards and specifications.

4. Proper training and supervision of the production team are necessary to ensure that everyone follows the established procedures and maintains consistency in production.

5. Continuous monitoring and improvement of the production process are necessary to address any issues that arise, refine techniques, and enhance overall quality control.

How Can Consistency in Production Ensure Quality Balls?

The Importance of Consistency in Production

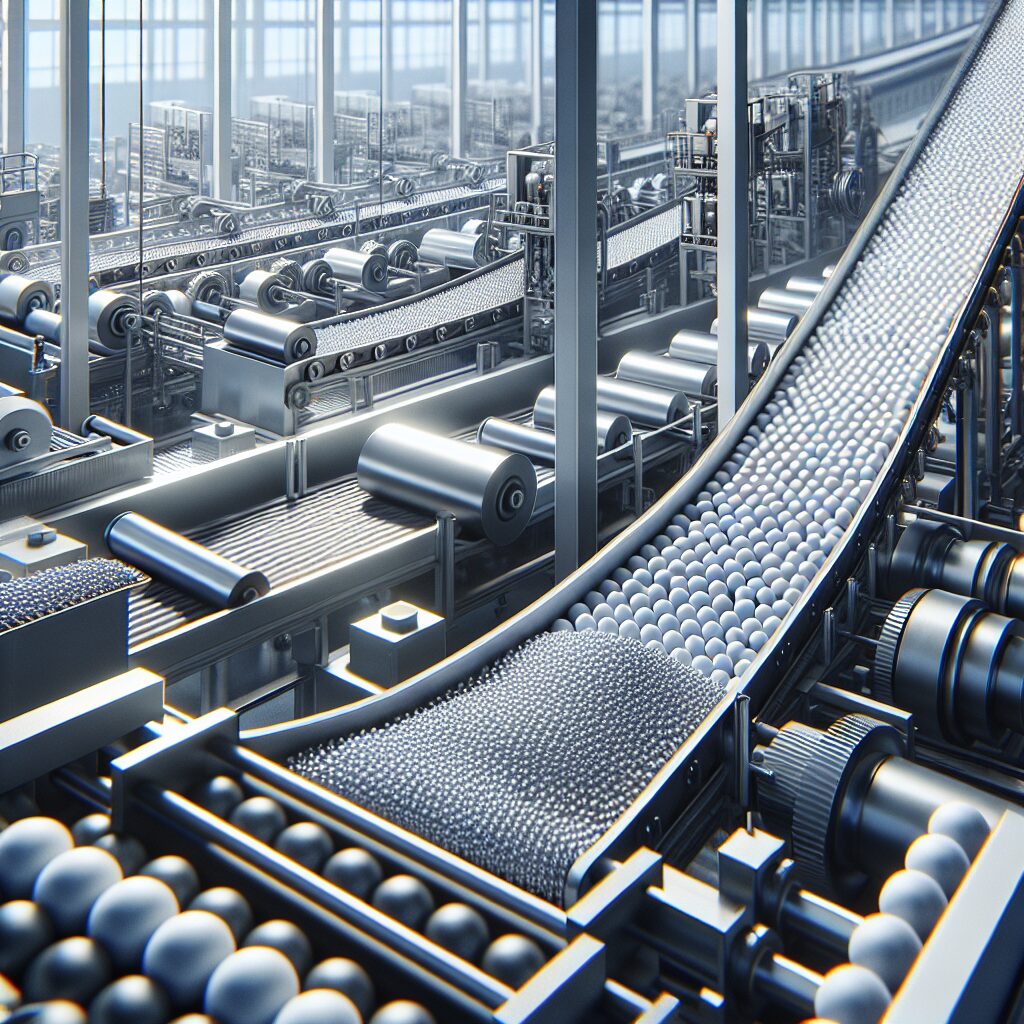

Consistency in production plays a crucial role in ensuring the quality of balls. When manufacturing balls, whether for sports or industrial purposes, maintaining consistency throughout the production process becomes paramount. It involves ensuring that each ball is produced with the same specifications, materials, and manufacturing techniques, resulting in a high level of uniformity and reliability.

Enhancing Performance and Durability

Consistency in production directly affects the performance and durability of balls. When all balls are manufactured with the same standards, they will exhibit consistent flight paths, bounce capabilities, and spin rates. This is particularly important in sports like tennis, golf, and soccer, where players rely heavily on the ball’s behavior to make precise shots. Additionally, balls produced consistently are more likely to withstand wear and tear, enhancing their durability and overall lifespan.

Promoting Fairness and Accuracy

In competitive sports, fairness and accuracy are of utmost importance. Consistency in production ensures that all players have equal opportunities as the balls they use exhibit identical characteristics. Whether it’s a tennis tournament or a golf championship, players can trust that each ball performs uniformly, eliminating any advantages or disadvantages caused by inconsistencies. This promotes fair play and creates a level playing field for all competitors.

Quality Control Measures

To achieve consistency in production, rigorous quality control measures must be put in place. Manufacturers need to establish strict guidelines and standard operating procedures to ensure that every aspect of the ball’s production adheres to predetermined specifications. This includes material selection, molding techniques, assembly processes, and quality testing. Regular inspections and random sampling should be conducted to identify any deviations and make necessary adjustments to maintain consistent production standards.

Benefits for Manufacturers

Consistency in production not only benefits the end-users but also the manufacturers themselves. By maintaining a consistent level of quality, manufacturers can establish a strong brand reputation and gain customer trust. This can lead to increased sales and customer loyalty. Moreover, consistent production allows manufacturers to streamline their operations, optimize resources, and reduce costs by minimizing waste and rejections.

Conclusion:

Ensure precise measurements and specifications:

Follow strict guidelines to ensure all balls are produced with accurate dimensions, weight, and materials.

Implement standardized manufacturing processes:

Have well-defined manufacturing processes in place to ensure consistency at each stage of production.

Perform regular quality checks:

Conduct inspections and quality tests to identify any variations and make necessary adjustments.

Invest in modern technology:

Utilize advanced machinery and equipment to improve precision and automate production processes.

Train and educate production staff:

Provide thorough training and education to the workforce on quality standards and best practices.

Frequently Asked Questions

1. What is consistency in production?

Consistency in production refers to the ability to produce items with the same quality, specifications, and performance consistently over time. It is the key to achieving reliable and high-quality products, including balls.

2. Why is consistency important in the production of balls?

Consistency is crucial in the production of balls as it ensures that each ball possesses the same properties, dimensions, and performance characteristics. This allows players to have a fair and consistent experience, promoting a level playing field and enhancing the overall quality of the game.

3. How can consistency be achieved in ball production?

Achieving consistency in ball production requires meticulous quality control processes, adherence to strict manufacturing standards, and the use of advanced technologies. Regular testing, calibration, and monitoring of production parameters are key to maintaining consistent quality throughout the manufacturing process.

4. What are the benefits of consistent ball production?

Consistent ball production has several benefits, including improved game performance, enhanced player satisfaction, and increased reliability. It ensures that players can trust in the integrity and quality of the balls they are using, leading to fair competition and accurate outcomes.

5. Can inconsistent production impact the performance of balls?

Yes, inconsistent production can have a direct impact on the performance of balls. Inconsistent dimensions, weight imbalances, or variations in bounce and flight characteristics can affect the ball’s playability and compromise its overall performance, leading to unfair game results and player frustrations.

6. How can consumers identify balls with consistent production?

Consumers can determine balls with consistent production by looking for reputable brands and manufacturers known for their quality control measures. Additionally, certifications or endorsements from official sports organizations can indicate that the balls meet stringent standards, ensuring consistency.

7. Are there any specific regulations or guidelines for ball production?

Yes, various sports organizations and regulatory bodies have set specific regulations and guidelines for ball production. These guidelines outline the required specifications, testing procedures, and quality control measures to ensure consistent production and fair play.

8. What role does technology play in achieving consistency in ball production?

Technology plays a vital role in achieving consistency in ball production. Advanced machinery, computer-controlled processes, and automated quality control systems enable manufacturers to maintain precise and consistent production parameters, minimizing human error and enhancing overall product quality.

9. How does consistent production contribute to sustainability?

Consistent production in ball manufacturing plays a role in sustainability by minimizing waste and reducing the environmental impact. When production processes are consistent, manufacturers can optimize material usage, minimize rejects, and adopt efficient manufacturing techniques, leading to resource conservation and a smaller carbon footprint.

10. Can consistent production be achieved across different types of balls?

Yes, consistent production can be achieved across different types of balls, including those used in various sports. Although the materials and specific requirements may differ, the principles of consistent manufacturing, quality control, and adherence to standards remain integral to ensuring uniformity and quality across ball production.

Final Thoughts on Consistency in Production: The Key to Quality Balls

Consistency in production is the foundation for delivering high-quality balls that meet the expectations and requirements of players, sports organizations, and consumers. By maintaining strict manufacturing standards, leveraging advanced technologies, and prioritizing quality control measures, manufacturers can ensure that every ball produced is reliable, consistent, and upholds the integrity of the game.

Consistent production not only enhances the playing experience but also fosters sustainability and trust in the industry. It enables athletes to perform at their best, coaches to strategize effectively, and fans to enjoy fair competitions. Therefore, it is imperative for manufacturers to prioritize consistency in production as it is the key to delivering quality balls that drive excellence in sports.