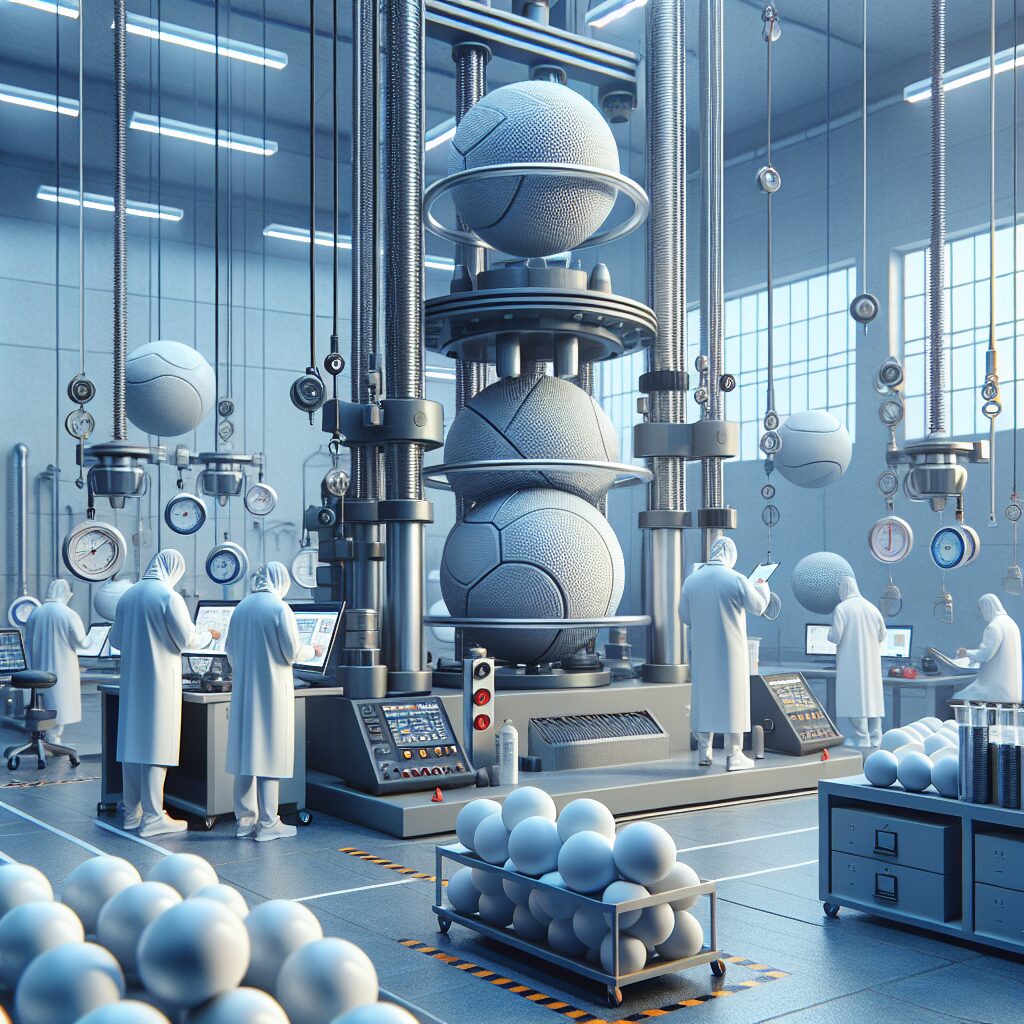

Testing laboratories play a crucial role in ensuring the quality of balls used in various industries, from sports equipment to industrial machinery. These labs are responsible for conducting rigorous tests and assessments to ensure that the balls meet the required standards and specifications. They use specialized equipment and techniques to examine the balls’ durability, performance, and safety. With their expertise and rigorous testing procedures, testing laboratories ensure that only high-quality balls enter the market, guaranteeing the satisfaction and safety of end-users.

One unique insight about testing laboratories is their ability to identify the subtle flaws or defects in balls that may not be visible to the naked eye. Through advanced testing methods such as non-destructive testing, X-ray imaging, and microscopic analysis, these labs can detect even the tiniest imperfections that could compromise the ball’s functionality. By uncovering such flaws, testing laboratories prevent potential accidents or equipment failure that could result from the use of low-quality balls.

In the upcoming sections, we will explore the key takeaways related to testing laboratories and their crucial role in ball quality. We will delve into the specific tests conducted by these labs, including impact resistance, compression strength, and material composition analysis. Additionally, we will discuss the importance of standardized testing procedures and the impact of testing lab certifications on the market. So, let us dive deeper into the world of testing laboratories and uncover how their meticulous work impacts the overall quality of balls.

Key Takeaways

1. Testing laboratories play a crucial role in ensuring the quality of balls used in various sports, including soccer, tennis, and golf. They conduct rigorous testing and certification processes to assess factors like durability, performance, and safety to ensure that the balls meet international standards.

2. These laboratories use advanced testing methods to evaluate ball characteristics such as compression, rebound, water absorption, and flight accuracy. This helps manufacturers improve the design and performance of their balls, ensuring an enhanced playing experience for athletes and enthusiasts.

3. Quality testing of balls helps prevent safety hazards by ensuring that they are durable and resistant to deformation or bursting. By subjecting balls to extreme conditions like high impact, pressure, and temperature, testing laboratories can identify weaknesses and recommend necessary improvements.

4. In addition to traditional testing, laboratories also conduct research to develop innovative materials and production techniques for manufacturing balls. This assists in creating high-quality products that are more sustainable, eco-friendly, and resistant to environmental conditions, such as temperature or moisture.

5. Collaborations between testing laboratories, manufacturers, and sporting organizations are essential to establishing and maintaining universally accepted ball standards. The continuous improvement in ball quality through testing contributes to fair and safe gameplay while providing athletes and sports enthusiasts with reliable and enjoyable experiences.

Why are Testing Laboratories Crucial in Ensuring Ball Quality?

The Importance of Testing Laboratories in Ball Manufacturing

Manufacturing high-quality balls requires meticulous testing procedures to ensure they meet industry standards. Testing laboratories play a crucial role in this process, providing vital information and certification for ball quality. Let’s explore the various aspects of testing laboratories in maintaining ball quality.

Materials Testing

One key aspect of ball quality is the materials used in their production. Testing laboratories analyze the composition of the materials to ensure they meet the required specifications. They conduct tests such as chemical analysis, density measurement, and tensile strength testing. These tests help identify any impurities or defects that could compromise the integrity and durability of the ball.

Functionality Testing

Testing laboratories also evaluate the functionality of balls through rigorous testing. For sports balls, this entails measuring factors like bounce rate, air retention, and durability. These tests ensure that the balls perform optimally in their respective sports and are capable of withstanding the demands of intense gameplay. Similarly, industrial balls undergo functionality tests to confirm their suitability for specific applications.

Performance and Durability Evaluation

To assess the performance and durability of balls, testing laboratories conduct extensive simulations and examinations. They simulate real-world conditions to gauge the balls’ ability to withstand impact, stress, and wear. By subjecting the balls to a battery of tests, including compression testing, deformation analysis, and fatigue testing, laboratories can accurately evaluate their overall performance and lifespan.

Compliance with Industry Standards

Testing laboratories ensure that balls comply with established industry standards and regulations. They certify the products based on these standards, providing manufacturers with essential documentation for quality assurance. Compliance with standards guarantees that consumers receive balls that meet the required safety, performance, and reliability criteria, providing peace of mind and confidence in their purchase.

Research and Development

Apart from testing existing ball models, laboratories also play a crucial role in the research and development of new ball technologies. By leveraging their expertise and cutting-edge testing equipment, they assist manufacturers in enhancing the quality and performance of their products. Through collaborative efforts and ongoing research, testing laboratories contribute to the continual improvement of ball quality standards.

Conclusion

Testing laboratories are an indispensable element in ensuring ball quality. Through materials testing, functionality evaluations, performance assessments, compliance certification, and research and development support, they contribute significantly to the production of high-quality balls. Manufacturers and consumers alike rely on the expertise and insights provided by these laboratories to ensure the balls they use meet the necessary standards.

How to choose a reliable testing laboratory for ball quality assessment?

When selecting a testing laboratory for assessing ball quality, it is crucial to consider factors such as accreditation, expertise, and turnaround time. Look for laboratories that hold certifications recognized by industry associations and have a proven track record in conducting similar tests. Additionally, inquire about their experience and capabilities in dealing with the specific type of balls you need to assess. Finally, ensure the laboratory can deliver timely results to avoid unnecessary delays in production.

What are the consequences of using balls that do not meet quality standards?

Using balls that do not meet quality standards can have various consequences. In sports, low-quality balls may exhibit unpredictable behavior, affecting gameplay and player performance. They could pose safety risks due to potential defects or inadequate durability. In industrial applications, using subpar balls can lead to inefficiencies, premature failures, and potential equipment damage. Therefore, it is vital to rely on testing laboratories to ensure the balls being used are of high quality and fit for purpose.

How can testing laboratories contribute to product innovation in the ball industry?

Testing laboratories play a crucial role in product innovation within the ball industry. By conducting research and development activities, they help manufacturers enhance the quality, performance, and durability of balls. Through advanced testing techniques and collaborations, these laboratories provide valuable insights and knowledge that fuel the development of innovative materials and manufacturing processes. Their contribution ultimately leads to the creation of superior ball products that meet the evolving needs and expectations of consumers.

Frequently Asked Questions

1. What is the role of a testing laboratory in ensuring the quality of balls?

A testing laboratory plays a crucial role in ensuring the quality of balls by conducting various tests and inspections. These tests evaluate the materials used, performance characteristics, durability, and safety of the balls. The laboratory’s expertise and equipment enable them to provide accurate assessments of the ball’s quality and adherence to industry standards.

2. How do testing laboratories determine if a ball meets safety requirements?

Testing laboratories follow established safety standards and guidelines to determine if a ball meets safety requirements. They conduct rigorous tests to assess factors such as the ball’s resilience, impact resistance, and stability under different conditions. By analyzing the test results, experts can conclude whether the ball is safe for use and complies with the necessary safety regulations.

3. What types of tests are commonly conducted in testing laboratories for balls?

Testing laboratories perform various tests on balls, including but not limited to:

– Impact tests to evaluate the ball’s ability to withstand forceful impacts without deformation.

– Compression tests to measure the ball’s resistance to compression forces.

– Drop tests to determine the ball’s durability by simulating accidental drops.

– Performance tests to assess factors like bounce, flight, and trajectory consistency.

– Material composition analysis to ensure the ball is made from appropriate and safe materials.

4. How do testing laboratories contribute to the development of innovative ball technologies?

Testing laboratories play a vital role in the development of innovative ball technologies. By conducting thorough tests on new materials, designs, and manufacturing processes, they can identify opportunities for improvement and provide valuable feedback to manufacturers. This collaboration between laboratories and manufacturers leads to the creation of balls with enhanced performance, durability, and safety features.

5. Can testing laboratories detect counterfeit balls?

Yes, testing laboratories have the expertise and equipment to detect counterfeit balls. Through detailed examinations and material analysis, they can identify discrepancies in the ball’s composition, construction, and performance characteristics. This helps in preventing the circulation of counterfeit balls in the market, ensuring that consumers receive authentic and high-quality products.

6. How long does it usually take for a testing laboratory to provide test results?

The turnaround time for test results may vary depending on the specific tests conducted, the complexity of the analysis, and the workload of the laboratory. However, most testing laboratories strive to provide timely results, aiming to deliver accurate assessments within a reasonable timeframe. It is best to inquire about the estimated turnaround time when submitting samples for testing.

7. Are the testing procedures standardized across different laboratories?

While there are generally accepted testing procedures for evaluating ball quality, there may be slight variations in specific protocols used by different laboratories. However, accredited laboratories follow established standards and guidelines set by industry organizations or regulatory bodies to ensure consistency and reliability in their testing processes.

8. Do testing laboratories provide certification for balls that pass quality tests?

Yes, testing laboratories often issue certifications for balls that pass quality tests. These certifications serve as tangible evidence that the ball has met the required standards and can be viewed as a mark of quality assurance. Manufacturers may use these certifications to enhance the credibility and marketability of their products.

9. Are testing laboratories involved in testing all types of balls?

Testing laboratories are involved in testing a wide variety of balls, including sports balls, industrial balls, medical balls, and more. They cater to the specific needs of different industries and ensure that the balls used in various applications meet the necessary quality and safety requirements.

10. How do testing laboratories contribute to consumer confidence in ball quality?

Testing laboratories play a fundamental role in building consumer confidence in ball quality. By conducting independent and rigorous tests, they provide unbiased evaluations of the balls’ performance, safety, and durability. This helps consumers make informed decisions when purchasing balls, knowing that they have been thoroughly tested and meet the required quality standards.

Final Thoughts on Testing Laboratories: The Crucial Role in Ball Quality

The role of testing laboratories in ensuring the quality of balls cannot be overstated. From evaluating safety aspects to performance characteristics, these laboratories utilize their expertise and cutting-edge equipment to provide accurate assessments that benefit both manufacturers and consumers. By collaborating with testing laboratories, manufacturers can overcome challenges, enhance their products, and cater to evolving market demands.

Furthermore, as consumers, we can trust that when we purchase balls that have been tested by accredited laboratories, we are investing in products that meet the necessary quality standards. Testing laboratories serve as guardians of ball quality and play a vital role in promoting innovation, safety, and consumer satisfaction in the realm of balls.