Quality Benchmarks: Shaping Excellence in Sports Balls

Sporting events are not just about the athletes and their skills; they also heavily rely on the equipment and tools used in the game. One such crucial element in various sports is the ball. From football to basketball, the quality of the ball can significantly impact the game’s overall performance and outcome. Considered the lifeline of any game, sports balls are constructed with precision and technology to enhance players’ experience and ensure fair gameplay.

One fascinating aspect of sports balls is the stringent quality benchmarks they need to meet. These benchmarks dictate the size, weight, shape, and performance characteristics of each ball. Manufacturers tirelessly work to conform to these benchmarks, ensuring consistency and reliability across their product lines. These quality standards are not only crucial for the athletes but also for the spectators, ensuring a level playing field and an enthralling match. As we delve into the world of quality benchmarks for sports balls, let’s explore the key takeaways, including the impact of quality on game performance and the unique features that set exceptional balls apart from the rest.

Key Takeaways

1. Ensuring quality control in sports ball production is essential to maintain product excellence and meet consumer demands. This includes testing materials, manufacturing processes, and performance characteristics to guarantee high-quality products that meet industry standards.

2. Stringent quality benchmarks and certifications help manufacturers and consumers identify trustworthy sports ball brands. Recognized certifications like FIFA Quality Pro and World Rugby approvals assure consumers of product quality and reinforce brand reputation.

3. Balancing compliance with safety standards and maintaining performance is crucial in sports ball manufacturing. Striking the right balance between factors such as bounce, grip, shape retention, and durability ensures that balls perform optimally without compromising player safety.

4. Continuous innovation and research play a vital role in improving sports ball quality. Manufacturers should invest in technologies that enhance performance characteristics and durability while staying up to date with the latest trends and demands in various sports.

5. Collaboration between manufacturers, sports federations, and test institutes is essential for setting and refining quality benchmarks. The ongoing partnership allows for better understanding of evolving requirements, ensures fair tests, and promotes consistency in quality across different sports balls.

What Are the SEO-Optimized Quality Benchmarks for Shaping Excellence in Sports Balls?

The Importance of Quality Benchmarks in Sports Balls

When it comes to sports balls, quality benchmarks play a crucial role in shaping excellence. These benchmarks are the standards and criteria that determine the overall quality, performance, and durability of sports balls. Whether it’s a soccer ball, basketball, tennis ball, or any other type of sports ball, having well-defined quality benchmarks ensures that athletes can enjoy optimal performance and safety during their games and practices.

Material Selection and Quality Control

One key aspect of quality benchmarks in sports balls is the material selection and quality control process. A high-quality sports ball must be made from durable and reliable materials that can withstand the rigors of play. This includes materials like leather, synthetic leather, rubber, or a combination of materials. Quality control measures are put in place to ensure that the materials used in sports balls meet specific standards and undergo rigorous testing before being approved for production.

Construction and Design Standards

The construction and design of sports balls also play a significant role in their overall quality and performance. Every aspect, from the shape and size to the panels and stitching, must adhere to specific construction and design standards. For example, a soccer ball must have the appropriate number of panels, stitching, and bladder to meet the quality benchmarks set by governing bodies like FIFA. Similarly, a basketball must have the right size, weight, and grip to ensure optimal play.

Performance Testing and Certification

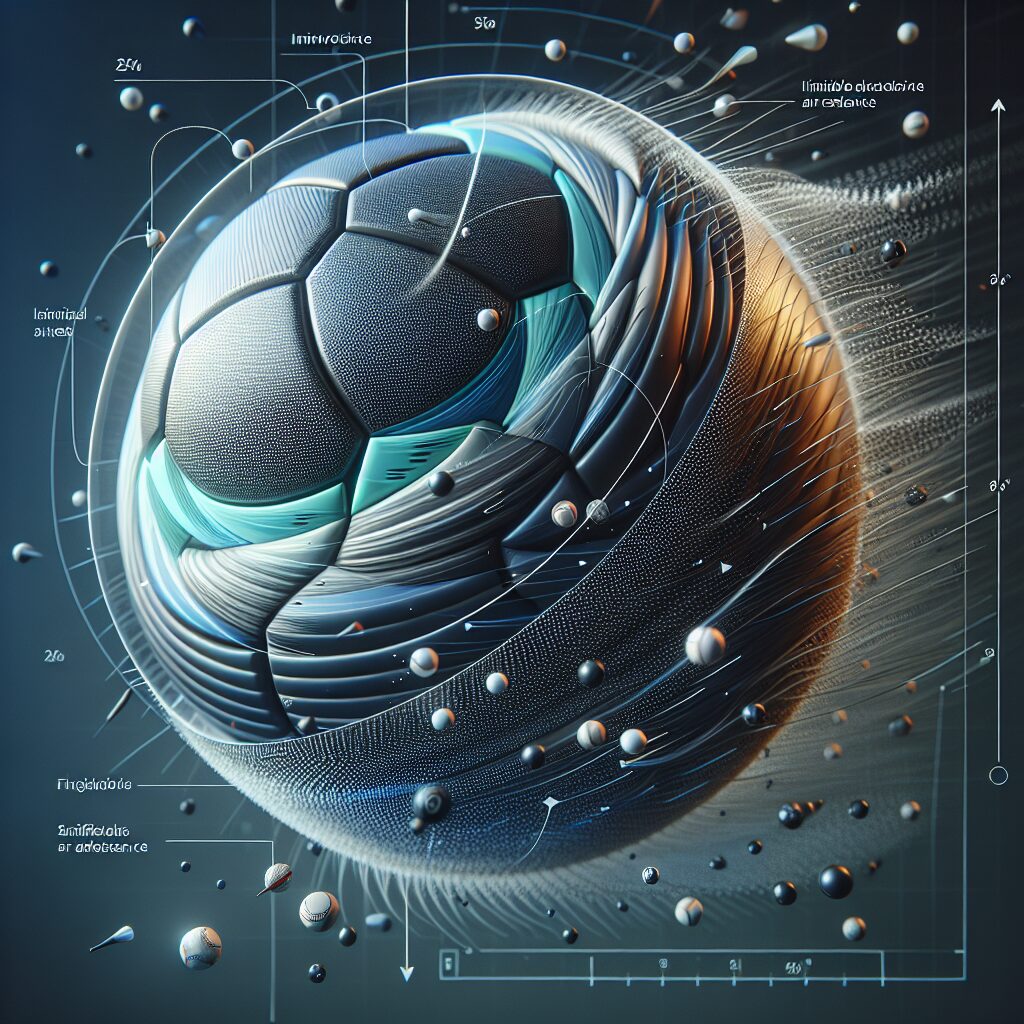

To ensure that sports balls meet the required quality benchmarks, performance testing and certification are essential steps. Sports organizations and governing bodies have specific testing protocols that assess various aspects of a ball’s performance, such as weight, bounce, flight, and durability. These tests help determine whether a sports ball meets the required standards and can be certified as high-quality and suitable for professional or recreational use.

Industry Standards and Compliance

Quality benchmarks for sports balls are not limited to individual organizations or governing bodies. There are also industry standards and compliance regulations that manufacturers must adhere to. These standards cover aspects like product labeling, safety guidelines, and environmental sustainability. By following these industry standards, manufacturers can ensure that their sports balls not only meet quality benchmarks but also align with broader societal goals and expectations.

Maintaining Quality and Continuous Improvement

Quality benchmarks for sports balls are not static; they should be dynamic and subject to continuous improvement. Manufacturers must constantly review and upgrade their processes to enhance the quality, performance, and safety of their sports balls. This includes incorporating customer feedback, leveraging new technologies, and staying updated with the latest research and innovations in sports ball manufacturing. By prioritizing quality benchmarks, manufacturers can ensure that sports balls continue to evolve and shape excellence in the world of sports.

5 Essential Tips for Meeting Quality Benchmarks in Sports Balls

- Invest in reliable and durable materials that can withstand the demands of intense play.

- Frequently test and assess the performance of sports balls to ensure they meet standards.

- Stay up to date with industry standards and compliance regulations to avoid any legal issues.

- Regularly seek customer feedback to understand their needs and expectations from sports balls.

- Continuously improve manufacturing processes by leveraging new technologies and research findings.

Frequently Asked Questions

1. What are quality benchmarks in sports balls?

Quality benchmarks in sports balls refer to the set standards and criteria that determine the level of excellence in the manufacturing, design, and performance of sports balls. These benchmarks ensure that sports balls meet specific requirements to guarantee their durability, performance, and safety.

2. Why are quality benchmarks important in sports balls?

Quality benchmarks are crucial in sports balls as they ensure consistent quality and performance across different brands and models. They help athletes choose reliable and safe equipment, enhance game performance, reduce the risk of injuries, and maintain the integrity of sports competitions.

3. How are quality benchmarks established and regulated?

Quality benchmarks in sports balls are established through extensive testing, research, and collaboration between industry experts, sports governing bodies, and manufacturers. Regulatory organizations such as FIFA, NBA, or FIFA certify and enforce these benchmarks, regularly updating them to incorporate technological advancements and address emerging concerns.

4. Are there specific quality benchmarks for different sports?

Yes, each sport establishes its own quality benchmarks for sports balls. Different sports have unique requirements in terms of size, weight, bounce, grip, and surface material of the balls. For example, soccer balls have distinct benchmarks regulated by FIFA, while basketballs have specific standards set by the NBA.

5. How can quality benchmarks impact player performance?

Quality benchmarks directly impact player performance as they ensure consistent and predictable ball behavior. Balls that meet high-quality standards offer better accuracy, control, and durability, allowing athletes to maximize their skills and technique during training and competitions. In contrast, subpar balls can hinder performance and affect the overall experience of the players.

6. How can consumers identify sports balls that meet quality benchmarks?

Consumers can identify sports balls that meet quality benchmarks by looking for certifications or marks of compliance from reputable regulatory organizations. These can be displayed on the packaging or product description. It is advised to purchase balls from well-known brands and authorized retailers who follow strict quality control measures.

7. Can quality benchmarks change over time?

Yes, quality benchmarks can change over time. As technology advances and new research emerges, sports governing bodies and manufacturers adapt and improve the benchmarks to ensure optimal performance, safety, and fairness in sports. It is essential for athletes and consumers to stay updated on any changes or new standards.

8. Do quality benchmarks apply to both professional and recreational sports balls?

Yes, quality benchmarks apply to both professional and recreational sports balls. While professional-level balls usually have more stringent requirements, recreational balls also need to meet certain benchmarks to ensure adequate performance and safety for players of all skill levels.

9. Are there any drawbacks to strict quality benchmarks?

Stricter quality benchmarks can lead to higher manufacturing costs, which may result in more expensive sports balls. Additionally, the stringent criteria could limit innovation or hinder the development of new materials and technologies. However, these potential drawbacks are outweighed by the benefits of consistent performance, player safety, and fair competition.

10. Can sports balls exceed quality benchmarks?

Yes, sports balls can exceed quality benchmarks. Some manufacturers go above and beyond minimum requirements to differentiate their products and provide enhanced features, performance, or durability. Exceeding quality benchmarks can be a competitive advantage for brands aiming to deliver superior sports equipment.

Final Thoughts

Quality benchmarks play a pivotal role in shaping excellence in sports balls. They ensure that athletes, whether professionals or amateurs, can trust in the performance, reliability, and safety of the balls they use. By adhering to these benchmarks, manufacturers contribute to the overall quality of sports and the satisfaction of players across different sports disciplines.

It is imperative for manufacturers, athletes, and consumers to prioritize quality benchmarks in sports balls to maintain fairness, reduce injuries, and elevate the overall sporting experience. As technology advances and the sporting landscape evolves, continuously reviewing and adapting these benchmarks will be vital to staying ahead and ensuring excellence in sports equipment.