Smart Technology: Transforming Ball Fabrication

In today’s ever-evolving world, smart technology has revolutionized various aspects of our daily lives. From intelligent personal assistants to futuristic self-driving cars, the possibilities seem endless. One area where smart technology has made significant advancements is in the field of ball fabrication. But what does this mean exactly? In simple terms, ball fabrication refers to the process of manufacturing balls, whether it be for sports, industrial purposes, or even entertainment. By incorporating smart technology into this process, manufacturers are able to achieve remarkable results that were previously unimaginable.

One unique fact about smart technology in ball fabrication is its ability to enhance performance and precision. Gone are the days when balls were produced solely based on traditional methods and craftsmanship. With the integration of smart technology, manufacturers can now fine-tune every intricate detail, ensuring optimal balance, weight, and aerodynamics. This level of precision not only enhances the overall performance of the ball but also provides athletes, professionals, and enthusiasts alike with an unparalleled experience. Additionally, smart technology enables real-time data collection and analysis, allowing manufacturers to gather valuable insights and make informed decisions to further improve the quality of the balls.

In the upcoming sections, we will delve deeper into the key takeaways of smart technology in ball fabrication. These fascinating advancements include the utilization of sensors for performance tracking, the integration of artificial intelligence for predictive analysis, and the incorporation of innovative materials for enhanced durability. By exploring these aspects, we will uncover the true potential of smart technology and how it continues to transform the world of ball fabrication. So, let’s dive in and explore the exciting possibilities that lie ahead!

Key Takeaways

1. Smart technology is revolutionizing ball fabrication, leading to greater accuracy, efficiency, and customization in the manufacturing process.

2. Sensors embedded in smart machines collect real-time data, enabling continuous monitoring and optimization of ball fabrication parameters such as heat, pressure, and material distribution.

3. The integration of artificial intelligence and machine learning algorithms allows smart machines to adapt and learn from data patterns, resulting in improved quality control and reduced defects.

4. Smart technology enables remote monitoring and control of the fabrication process, allowing manufacturers to troubleshoot and make adjustments in real-time, leading to increased productivity and reduced downtime.

5. The use of smart technology in ball fabrication opens up possibilities for new materials, designs, and applications that were previously unachievable, offering exciting opportunities for innovation in various industries.

How Can Smart Technology Revolutionize Ball Fabrication?

Benefits of Smart Technology in Ball Fabrication

Smart technology has brought significant advancements in various industries, and ball fabrication is no exception. By incorporating smart technology, manufacturers are witnessing remarkable improvements in the production process. Firstly, smart technology enables precise and efficient ball fabrication, resulting in balls that meet precise specifications. Additionally, it enhances the consistency and quality of the produced balls, ensuring optimal performance and durability.

Integration of Artificial Intelligence (AI) in Ball Fabrication

One of the key components of smart technology in ball fabrication is the integration of artificial intelligence. AI algorithms analyze data collected during the fabrication process, allowing manufacturers to identify patterns, detect defects, and predict potential issues. This enables proactive maintenance, reducing downtime and improving overall productivity. Moreover, AI enhances the accuracy of fabrication by continuously learning and adapting to optimize the manufacturing parameters.

Internet of Things (IoT) in Ball Fabrication

The Internet of Things plays a crucial role in revolutionizing ball fabrication. IoT devices, equipped with sensors, gather real-time data from different stages of the production process. This data is then transmitted to a centralized system for analysis. By monitoring variables such as temperature, pressure, and machine performance, manufacturers can identify inefficiencies and optimize the fabrication process. IoT-enabled ball fabrication also enables remote monitoring and control, minimizing the need for manual intervention.

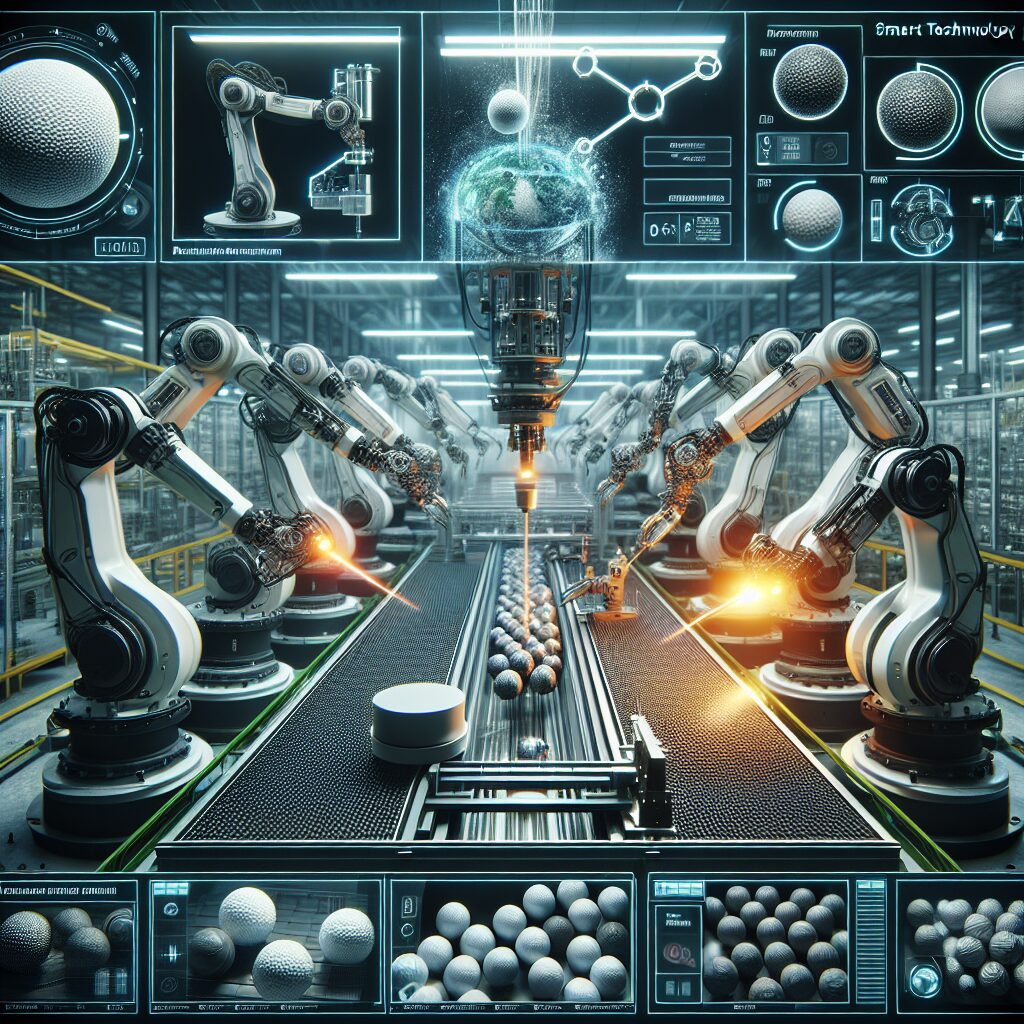

Automation and Robotics in Ball Fabrication

Smart technology in ball fabrication has led to the implementation of automation and robotics. Automated systems can perform tasks such as sorting, polishing, and inspection with great precision and speed. By reducing human involvement, manufacturers achieve higher production rates and minimize errors. Robotics further enhance the fabrication process by handling complex operations and ensuring consistent quality. Overall, automation and robotics streamline ball fabrication, resulting in increased efficiency and reduced costs.

Data Analytics and Predictive Maintenance

With smart technology, manufacturers can leverage data analytics to gain valuable insights into the ball fabrication process. By analyzing historical data, manufacturers can identify trends, patterns, and correlations, helping them optimize production parameters and minimize defects. Additionally, predictive maintenance algorithms use data from sensors and AI models to anticipate equipment failures, enabling proactive maintenance that prevents costly downtime.

Challenges in Implementing Smart Technology for Ball Fabrication

While the benefits of smart technology in ball fabrication are evident, there are certain challenges associated with implementation. First and foremost is the initial investment required to adopt smart technology solutions. Manufacturers need to invest in advanced machinery, IoT devices, and data analysis systems. Additionally, training the workforce to operate and maintain these technologies is crucial for successful implementation. Lastly, ensuring data security and privacy is of utmost importance, as interconnected systems are vulnerable to cyber threats.

Key Tips for Embracing Smart Technology in Ball Fabrication

- Engage in thorough research to identify the most suitable smart technology solutions for your ball fabrication process.

- Invest in high-quality smart machinery and equipment to ensure optimal performance and efficiency.

- Train your workforce to effectively operate and maintain smart technology systems, reducing the learning curve.

- Implement robust data security measures to protect sensitive information and prevent potential cyberattacks.

Frequently Asked Questions

1. What is Smart Technology and how is it transforming ball fabrication?

Smart Technology refers to the integration of digital intelligence and connectivity into traditional objects or devices. In the context of ball fabrication, Smart Technology allows for the use of advanced sensors, data analysis, and automation to improve the manufacturing process, resulting in higher quality and more efficient production of balls.

2. What are the key benefits of utilizing Smart Technology in ball fabrication?

By employing Smart Technology in ball fabrication, manufacturers can achieve greater accuracy in ball production, reduce defects and inconsistencies, optimize production cycles, and enhance overall product quality. It also enables real-time monitoring and analysis of production data, facilitating proactive maintenance and minimizing downtime.

3. How does Smart Technology enhance quality control in ball fabrication?

Smart Technology introduces various sensors and monitoring devices that constantly collect data on factors like temperature, pressure, and vibration during the fabrication process. This real-time data can be analyzed using machine learning algorithms to identify patterns and potential issues, allowing for timely adjustments and interventions to ensure optimal quality control.

4. Does the integration of Smart Technology in ball fabrication lead to job losses?

While the adoption of Smart Technology may change certain job requirements and responsibilities, it also creates new opportunities for skilled workers to manage and maintain the technological systems. Additionally, the increased efficiency and quality achieved through Smart Technology can lead to business growth and the creation of new jobs in related areas.

5. Can Smart Technology be implemented in all types of ball fabrication?

Yes, Smart Technology can be incorporated into various types of ball fabrication processes, including those involving sports balls, industrial balls, and precision balls. The specific implementation may vary depending on the requirements and complexities of each manufacturing process.

6. What role does data analysis play in Smart Technology-driven ball fabrication?

Data analysis is a critical component of Smart Technology-driven ball fabrication. By collecting and analyzing production data, manufacturers can gain valuable insights into process optimization, predictive maintenance, and quality improvements. Data-driven decision-making enhances efficiency, reduces costs, and leads to continuous innovation.

7. Is Smart Technology cost-effective for small-scale ball manufacturers?

Implementing Smart Technology in ball fabrication can initially involve some investment in devices, systems, and training. However, the long-term benefits, such as improved quality, reduced downtime, and streamlined production, outweigh the initial costs. Smart Technology adoption can ultimately lead to cost savings and competitive advantages, making it viable for small-scale ball manufacturers as well.

8. What are the potential challenges in adopting Smart Technology for ball fabrication?

Some challenges in adopting Smart Technology for ball fabrication include the initial capital investment, integrating the new technology into existing processes, and training personnel to effectively utilize and maintain the technology. Additionally, cybersecurity and data privacy concerns should be addressed to ensure the protection of sensitive production data.

9. Can Smart Technology improve sustainability in ball fabrication?

Yes, Smart Technology can contribute to sustainability in ball fabrication through optimized resource utilization, reduced waste, and energy-efficient production processes. By closely monitoring and controlling various parameters, manufacturers can minimize environmental impact and enhance the sustainability of their operations.

10. Are there any regulatory and safety considerations related to Smart Technology in ball fabrication?

As with any technological advancement, there may be regulatory and safety considerations when implementing Smart Technology in ball fabrication. Compliance with industry standards, data protection regulations, and ensuring worker safety are important factors that manufacturers need to address while integrating Smart Technology into their processes.

Final Thoughts

Smart Technology has revolutionized ball fabrication, enabling manufacturers to elevate the quality, efficiency, and sustainability of their production processes. By leveraging advanced sensors, data analysis, and automation, Smart Technology offers valuable insights, precise control, and real-time monitoring, resulting in superior ball products. While challenges such as initial investment and skill adaptation exist, the long-term benefits and potential for growth make Smart Technology an essential tool in the ever-evolving world of ball fabrication.

With the continuous advancements and innovations in Smart Technology, we can expect further improvements in ball fabrication, propelling the industry towards unprecedented levels of precision and performance. As manufacturers embrace this transformative technology, it opens up exciting possibilities for creating even better balls that meet the evolving needs of various sectors, from sports to industrial applications.