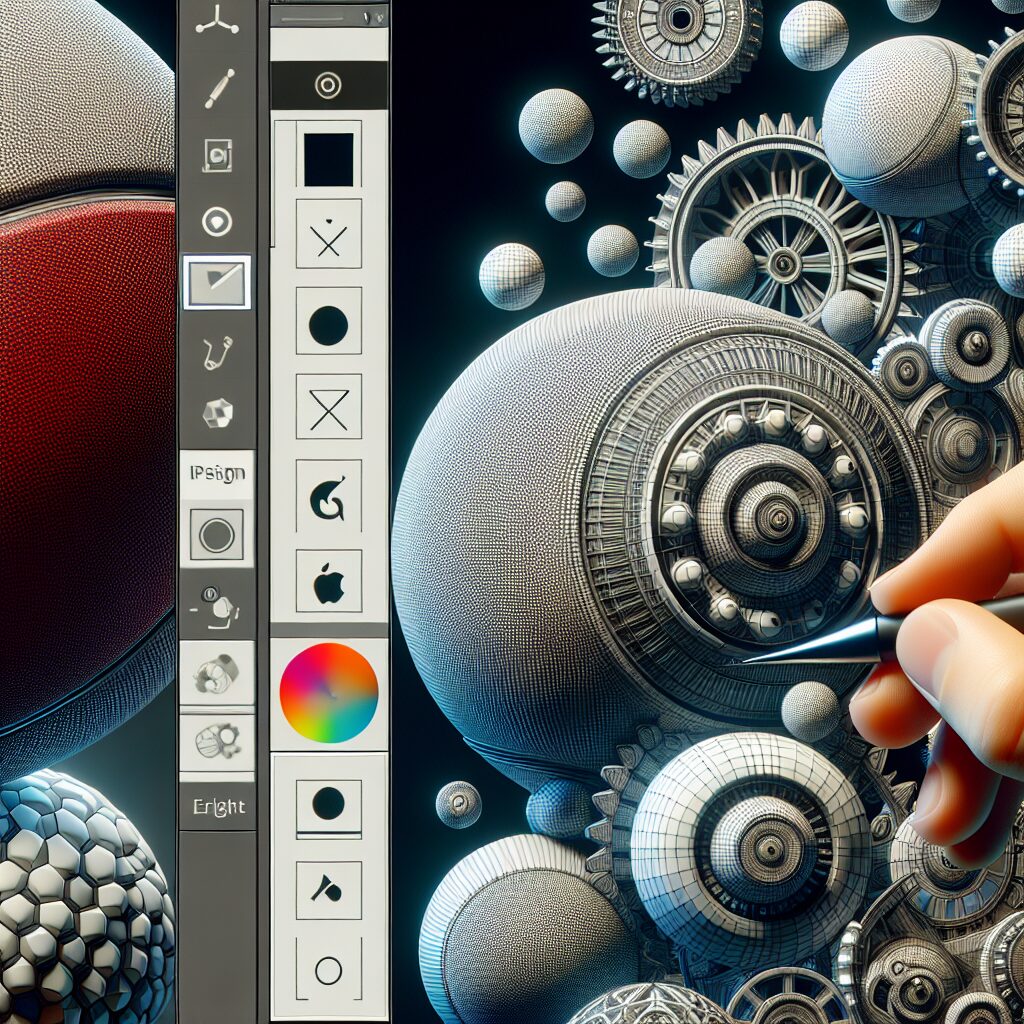

Digital design has revolutionized various industries, and one area that has greatly benefited from this technological advancement is ball fabrication. In simple terms, digital design refers to the creation of visual and functional elements using computer software and tools. When it comes to ball fabrication, digital design has introduced innovative techniques that have redefined the production process.

One unique fact about digital design in ball fabrication is its ability to create highly accurate and precise designs. With the help of advanced software and tools, manufacturers can now create intricate designs for balls of different shapes and sizes. This level of precision not only enhances the overall quality of the product but also contributes to improved performance on the field. Additionally, digital design allows for customization, enabling manufacturers to create unique and personalized balls to meet the specific requirements of players or teams.

Now, let’s delve into the key takeaways of this article. We will explore the impact of digital design on the durability and performance of fabricated balls. Furthermore, we will discuss how the customization options offered by digital design have revolutionized the market. Finally, we will delve into the future possibilities and potential advancements in ball fabrication through the lens of digital design. So, continue reading to discover how digital design is revolutionizing ball fabrication and transforming the way we play sports.

Key Takeaways

1. The digital design process has revolutionized ball fabrication by eliminating manual labor and allowing for precise customization based on specific player needs.

2. Utilizing computer-aided design (CAD) software and 3D printing technology, manufacturers can create balls with unique patterns and textures, improving grip and control for athletes.

3. The ability to digitally simulate and test different ball designs before production has significantly reduced the time and cost associated with traditional trial and error methods.

4. Digital fabrication enables manufacturers to respond quickly to market demands, producing customized balls for various sports and catering to individual preferences, enhancing player performance.

5. By embracing digital design, the ball fabrication industry has embraced innovation, leading to more durable, aerodynamic, and advanced balls that enhance gameplay and elevate athletes’ experiences.

How Can Digital Design Redefine Ball Fabrication?

Advancements in Digital Design Technology

Digital design has revolutionized various industries, and now it is transforming ball fabrication processes. With the advent of sophisticated computer software and 3D modeling, designers can create and manipulate ball designs like never before. This enables precise customization, optimization, and superior performance.

Improved Precision and Accuracy

Digital design allows for precise control over every aspect of ball fabrication. Designers can now adjust diameter, weight distribution, surface texture, and other crucial factors with utmost accuracy. This level of precision ensures that the final product meets the desired specifications, leading to enhanced performance and reduced manufacturing defects.

Efficiency in Design Iteration

Gone are the days of endless physical prototypes and time-consuming adjustments. With digital design, ball fabrication engineers can quickly iterate through multiple design variations in a virtual environment. This streamlined process significantly reduces the time and cost required for fabrication. Designs can be modified and optimized with ease, ensuring the best possible outcome.

Complex Geometries and Customization

Digital design empowers engineers to explore innovative ball geometries that were previously unattainable using traditional fabrication techniques. From intricate patterns to unconventional shapes, the possibilities are endless. Moreover, digital tools allow for easy customization, enabling the creation of personalized balls tailored to specific applications and user preferences.

Material Selection and Simulation

Digital design provides a comprehensive understanding of how different materials behave in ball fabrication. Engineers can simulate the behavior of various materials, considering factors such as elasticity, durability, and friction. This knowledge allows for informed decisions when selecting the most suitable materials for the desired performance and application requirements.

The Future of Ball Fabrication

Digital design is rapidly evolving, and its impact on ball fabrication is poised to grow further. As computational power increases and software becomes more sophisticated, designers will have even more tools at their disposal. The future holds exciting possibilities for optimizing ball performance, durability, and overall functionality. The potential applications span across various industries, including sports, automotive, machinery, and more.

Enhance Your Ball Fabrication Process with These Tips:

- Invest in advanced digital design software and tools to unlock the full potential of ball fabrication customization.

- Collaborate with materials experts to understand the behavior and characteristics of different materials, enabling informed material selection.

- Utilize 3D printing technology for rapid prototyping and quick iteration of ball designs.

- Stay updated on the latest advancements in digital design and take advantage of new features and techniques to push the boundaries of ball fabrication.

- Experiment with complex geometries and innovative designs to uncover new possibilities and performance improvements.

Frequently Asked Questions

1. What is digital design in the context of ball fabrication?

Digital design refers to the use of computer-aided design (CAD) software and other digital tools to create and manipulate ball designs. It allows for precise control over the shape, size, and surface texture of balls, leading to more accurate and customizable fabrication.

2. How does digital design improve ball fabrication?

Digital design enables engineers to optimize ball performance by fine-tuning various parameters, such as core shape, weight distribution, and coverstock composition. This results in balls with enhanced overall performance, improved pin carry, better hitting power, and increased durability.

3. Can digital design be used for all types of balls?

Yes, digital design can be applied to various types of balls, including bowling balls, soccer balls, basketballs, golf balls, and more. It allows for precision engineering tailored to the specific requirements and performance characteristics of each ball type.

4. Are digitally designed balls more expensive?

The cost of digitally designed balls can vary depending on factors such as the complexity of the design, the materials used, and the manufacturing process. However, in many cases, the benefits of improved performance and durability outweigh any potential increase in price.

5. Are digitally designed balls more prone to defects?

No, digitally designed balls are not inherently more prone to defects. In fact, the use of digital design tools can help identify and eliminate potential manufacturing flaws early in the process, resulting in balls with higher quality and consistency.

6. Can digital design improve ball customization?

Yes, digital design allows for greater customization of balls. It enables manufacturers to offer a wider range of options in terms of weight, balance, surface finishes, and even personalized graphics. This ensures that each player can find a ball that suits their specific needs and preferences.

7. Does digital design impact the performance of professional athletes?

Yes, digital design plays a significant role in enhancing the performance of professional athletes. By providing balls with superior performance characteristics, it allows athletes to achieve higher scores, greater accuracy, and improved consistency in their respective sports.

8. Can digital design influence the aerodynamics of balls?

Yes, digital design can optimize the aerodynamics of balls to improve their flight characteristics. For example, in golf balls, digital design can enhance dimple patterns to achieve greater lift and distance. Similarly, in soccer balls, it can improve stability and trajectory during kicks.

9. What are some challenges in digital design for ball fabrication?

Some challenges in digital design for ball fabrication include accurately simulating real-world conditions, managing complex geometries, and finding the right balance between performance and manufacturability. However, advancements in CAD software and additive manufacturing techniques are helping to overcome these challenges.

10. Is digital design the future of ball fabrication?

Undoubtedly, digital design is already revolutionizing the field of ball fabrication, and it will continue to shape its future. As technology advances and our understanding of materials and performance improves, digital design will play an even more critical role in pushing the boundaries of what is possible in ball design and fabrication.

Final Thoughts

Digital design has unlocked new possibilities in the world of ball fabrication. By harnessing the power of CAD software and other digital tools, manufacturers can create balls with exceptional performance characteristics, tailored to the needs of professional athletes and casual players alike. The precision and customization offered by digital design enhance not only the overall playing experience but also the competitiveness of various sports.

As we move forward, we can expect digital design to continue evolving rapidly, enabling even more innovative and groundbreaking ball designs. With ongoing advancements, the future of ball fabrication looks incredibly exciting, promising enhanced performance, increased personalization options, and pushing the boundaries of athletic achievements. Digital design is truly redefining the world of ball fabrication, making it more accessible, efficient, and thrilling for players across different sports.