Sustainable production refers to the process of manufacturing products while minimizing negative environmental impacts and optimizing the use of resources. In the context of eco-friendly ball fabrication, sustainable production aims to create sports equipment that is both high-quality and environmentally responsible. With the increasing awareness of climate change and the need to reduce our carbon footprint, sustainable production methods have become essential in the sports industry. One unique fact pertaining to this topic is that eco-friendly ball fabrication involves using materials and processes that minimize the release of harmful substances into the environment, making it a greener alternative.

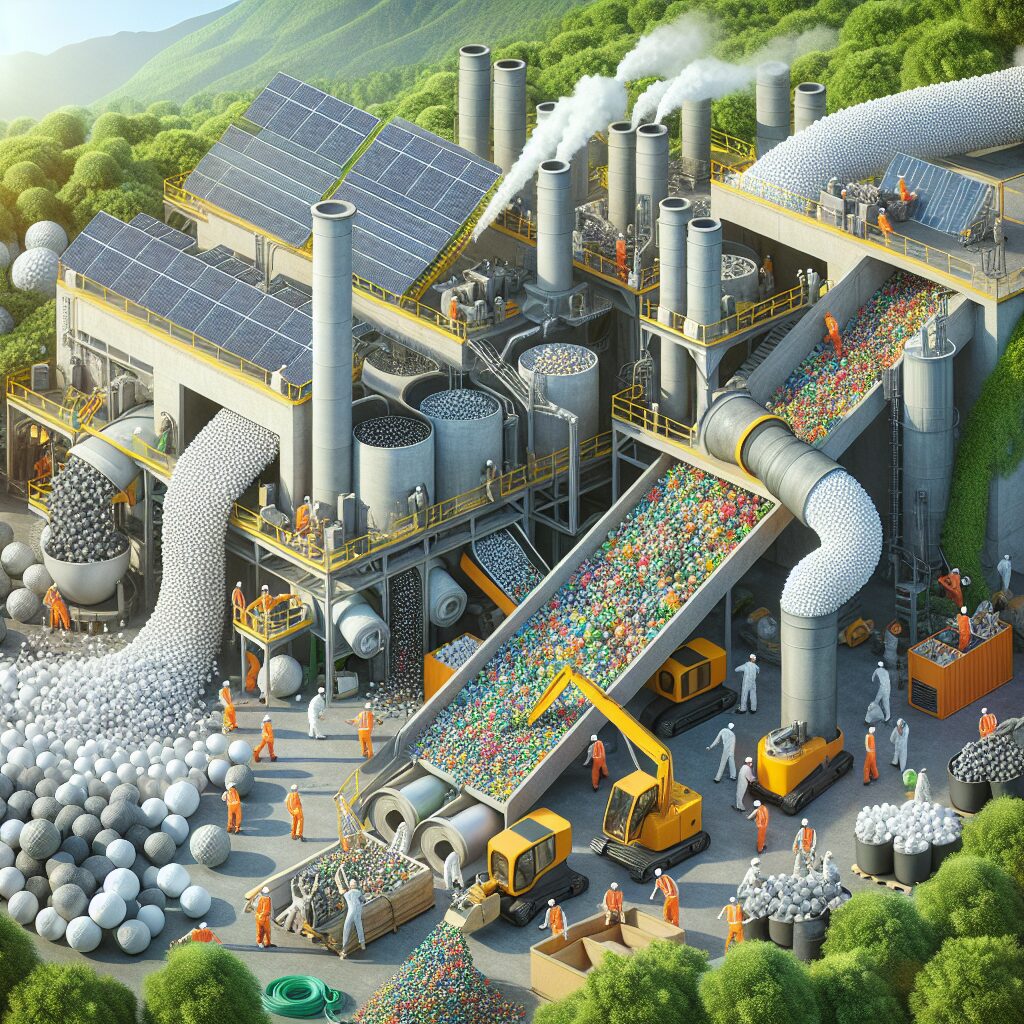

When it comes to eco-friendly ball fabrication, there are several specific impacts and unique features to consider. Firstly, the use of sustainable materials, such as organic cotton or recycled polyester, reduces the reliance on non-renewable resources and minimizes the generation of waste. Additionally, eco-friendly ball fabrication often involves utilizing eco-conscious manufacturing processes, such as dyeing methods that consume less water and energy. Another important aspect is ensuring the durability of the ball, which extends its lifespan and reduces the need for frequent replacements.

As we explore the key takeaways of sustainable production in eco-friendly ball fabrication, we will delve into the benefits for both the environment and athletes. We will investigate the various sustainable materials used in the manufacturing process and how they contribute to reducing the carbon footprint. Furthermore, we will explore the innovative manufacturing techniques employed, which not only minimize environmental impacts but also ensure the quality and performance of the ball. By embracing a sustainable approach in ball fabrication, we can create sports equipment that not only enhances athletic performance but also helps preserve the planet for future generations. Stay tuned as we delve deeper into these fascinating aspects of sustainable production in eco-friendly ball fabrication.

Key Takeaways

1. Sustainable production methods are crucial for mitigating the environmental impact of ball fabrication.

2. Eco-friendly materials, such as recycled plastic bottles and organic cotton, are being used in the production of eco-conscious balls.

3. Implementing sustainable practices, such as reducing water usage and utilizing renewable energy sources, helps to reduce the carbon footprint of ball production.

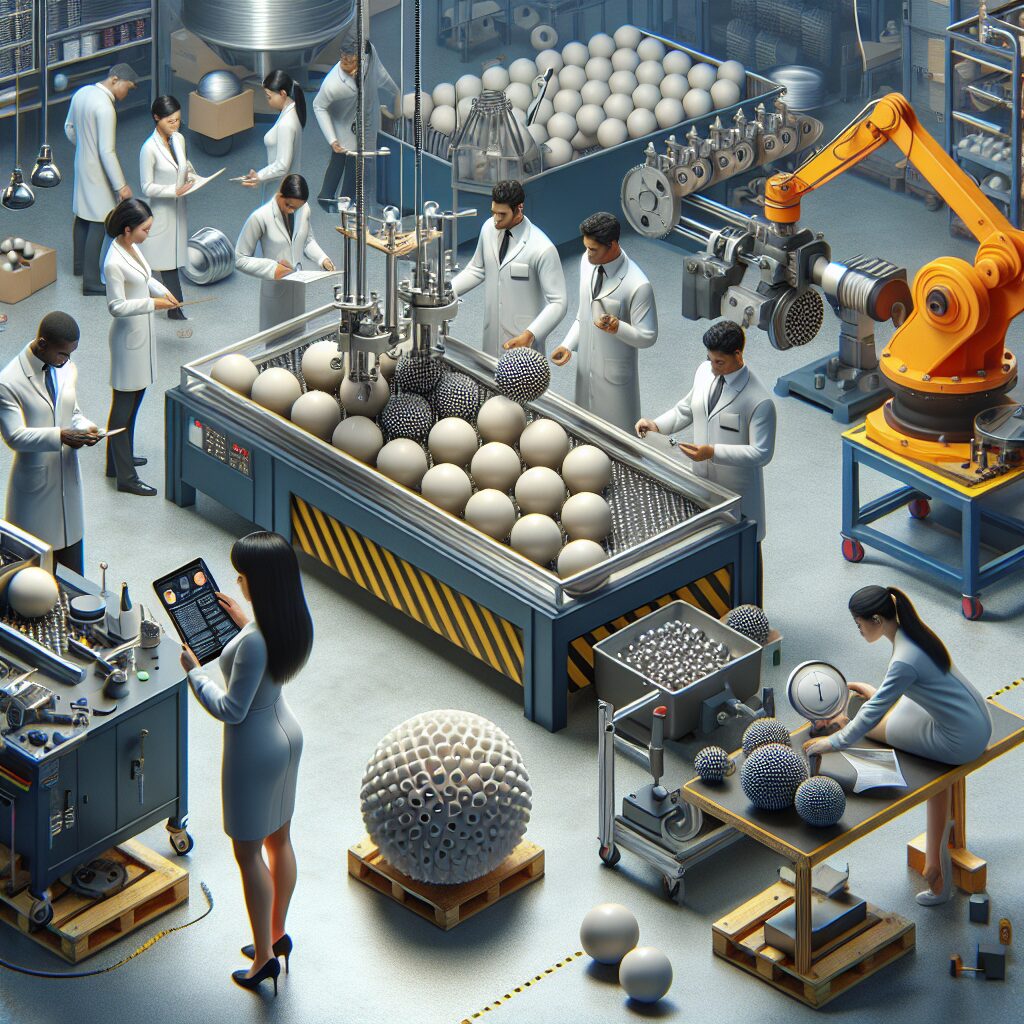

4. The adoption of innovative technologies, like 3D printing and automation, can enhance the efficiency and sustainability of ball fabrication processes.

5. Collaborative efforts between manufacturers, designers, and consumers are necessary to drive widespread adoption of sustainable production methods within the ball manufacturing industry.

Is Sustainable Production Possible for Eco-Friendly Ball Fabrication?

Understanding Sustainable Production

Sustainable production involves creating and manufacturing products in an environmentally and socially responsible way. This approach aims to minimize resource consumption, reduce waste generation, and promote the use of eco-friendly materials throughout the production process.

The Importance of Eco-Friendly Ball Fabrication

Ball fabrication, particularly in sports industries, has a significant impact on the environment due to the materials used and the manufacturing processes involved. Embracing eco-friendly ball fabrication is crucial to reduce this impact and ensure a sustainable future.

Eco-Friendly Materials for Ball Fabrication

Choosing the right materials is a fundamental aspect of eco-friendly ball fabrication. Materials should be non-toxic, biodegradable or recyclable, and sourced sustainably. Some examples of eco-friendly materials used in ball fabrication include organic cotton, natural rubber, and recycled plastics.

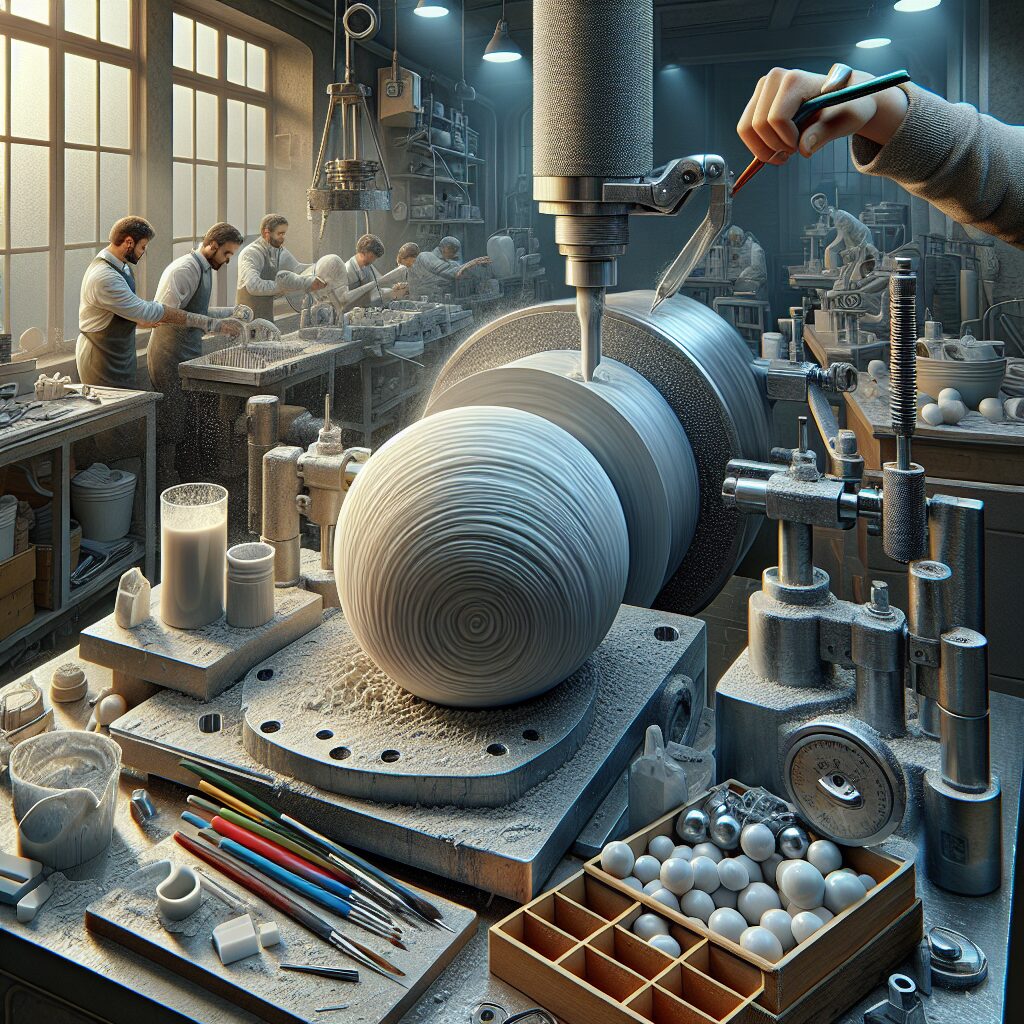

Innovative Manufacturing Techniques

Embracing innovative manufacturing techniques is vital for sustainable ball fabrication. By utilizing processes that minimize energy consumption and waste generation, such as 3D printing or waterless dyeing, manufacturers can significantly reduce their environmental footprint.

Supply Chain Transparency and Ethical Practices

Ensuring transparency throughout the supply chain is crucial for sustainable ball production. Manufacturers should prioritize working with suppliers who adhere to ethical labor practices and demonstrate responsible sourcing. By doing so, they contribute to a socially responsible and sustainable production ecosystem.

Collaboration with Research and Development

Collaborating with research and development departments allows for continuous improvements in eco-friendly ball fabrication. By investing in research, manufacturers can discover and implement new technologies, materials, and processes that further enhance sustainability in their production practices.

Evaluating the Total Environmental Impact

Assessing the total environmental impact of ball fabrication is essential to make informed decisions and identify areas for improvement. Manufacturers should conduct life cycle assessments to understand the environmental implications at each stage, including material extraction, production, transportation, and end-of-life disposal.

Educating Consumers and Promoting Sustainable Choices

Encouraging consumers to make sustainable choices is critical for the success of eco-friendly ball fabrication. Manufacturers should invest in consumer education and clearly communicate the environmental benefits of their products. This empowers consumers to choose eco-friendly balls, creating a demand that further drives sustainable production.

Conclusion:

5 Tips for Sustainable Production: Eco-Friendly Ball Fabrication

- Choose eco-friendly materials such as organic cotton and natural rubber for ball fabrication.

- Embrace innovative manufacturing techniques that minimize energy consumption and waste generation.

- Prioritize supply chain transparency and ethical practices to ensure sustainable production.

- Collaborate with research and development departments to continuously improve sustainability practices.

- Educate consumers about the environmental benefits of eco-friendly balls and encourage sustainable choices.

FAQ

1. What is sustainable production?

Sustainable production refers to the process of manufacturing goods in a way that minimizes negative environmental impact by making use of eco-friendly practices, materials, and technologies.

2. Why is sustainable production important?

Sustainable production is important because it helps protect the environment, minimize resource depletion, reduce pollution, and promotes the well-being of communities by adopting environmentally conscious practices.

3. What are eco-friendly balls?

Eco-friendly balls are sports balls or recreational balls that are made using sustainable materials and processes, ensuring they have a minimal carbon footprint and do not harm the environment. These balls are often manufactured using recycled or organic materials.

4. Are eco-friendly balls as durable as traditional balls?

Yes, eco-friendly balls can be just as durable as traditional ones. With advancements in technology and manufacturing techniques, sustainable materials such as recycled rubber or organic textiles can be used to create balls that offer the same level of durability and performance.

5. How are eco-friendly balls different from regular balls?

Eco-friendly balls are different from regular balls in terms of their materials and production methods. While regular balls may contain harmful substances or be manufactured using non-renewable resources, eco-friendly balls prioritize using sustainable materials and processes to reduce their environmental impact.

6. Can eco-friendly balls be used for professional sports?

Yes, eco-friendly balls can be used for professional sports. As long as they meet the required standards and performance criteria, eco-friendly balls are suitable for various sports disciplines, including professional tournaments.

7. How can sustainable production benefit the sports industry?

Sustainable production can benefit the sports industry by reducing its ecological footprint. By adopting eco-friendly practices in ball fabrication, sports companies can contribute to a cleaner environment, build a positive brand image, and attract environmentally conscious customers.

8. Are eco-friendly balls more expensive than traditional balls?

Typically, eco-friendly balls may have a slightly higher price compared to traditional balls due to the use of sustainable materials and production methods. However, as sustainable production becomes more mainstream and economies of scale are achieved, the price difference is likely to decrease.

9. Can eco-friendly ball fabrication contribute to job creation?

Yes, eco-friendly ball fabrication can contribute to job creation. The adoption of sustainable production practices often requires new expertise and technologies, leading to employment opportunities in research and development, manufacturing, and supply chain management.

10. How can consumers support eco-friendly ball fabrication?

Consumers can support eco-friendly ball fabrication by choosing to purchase and use eco-friendly balls instead of traditional ones. By creating demand for sustainable products, consumers can encourage companies to invest further in sustainable production methods and contribute to a greener future.

Final Thoughts

Sustainable production in the context of ball fabrication is not just a trend; it is a crucial step towards creating a more environmentally conscious and responsible sports industry. By embracing eco-friendly materials, innovative manufacturing techniques, and supply chain transparency, we can ensure that the production of sports balls aligns with our global sustainability goals.

As consumers, athletes, and sports enthusiasts, we have the power to make a positive impact by supporting and demanding eco-friendly balls. By choosing sustainable options, we directly contribute to preserving our environment, promoting a circular economy, and fostering a more sustainable future for sports and beyond.