Innovative Durability Testing: Advancing Ball Technology is a fascinating topic that explores the cutting-edge methods used to assess the durability and performance of various types of balls. Whether it’s tennis balls, soccer balls, or basketballs, manufacturers are continuously striving to enhance their products’ longevity and functionality. In this article, we will delve into the realm of innovative durability testing and examine the impact it has on ball technology. From the incorporation of advanced materials to the development of state-of-the-art testing techniques, we will uncover the unique features that contribute to the evolution of ball durability.

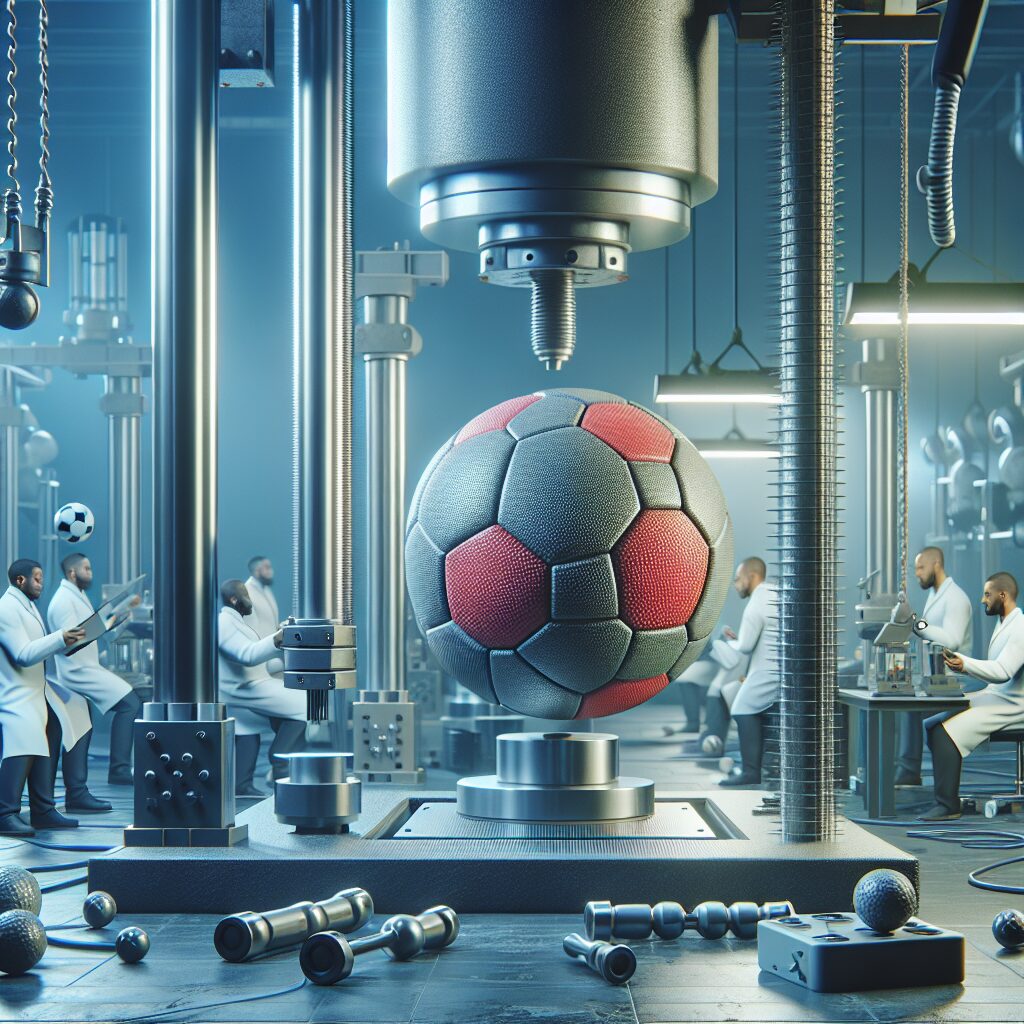

One intriguing aspect of innovative durability testing is the utilization of high-tech instruments to simulate real-life conditions. By subjecting balls to extreme temperatures, intense pressure, and repetitive impacts, researchers are able to assess their ability to withstand the rigors of various sports. This allows manufacturers to identify weaknesses and areas of improvement, resulting in the production of more durable and reliable balls. Furthermore, the integration of advanced materials such as synthetic rubbers and reinforced fibers contributes to the enhanced durability of modern-day balls. These advancements not only extend the lifespan of sports equipment but also significantly impact gameplay dynamics.

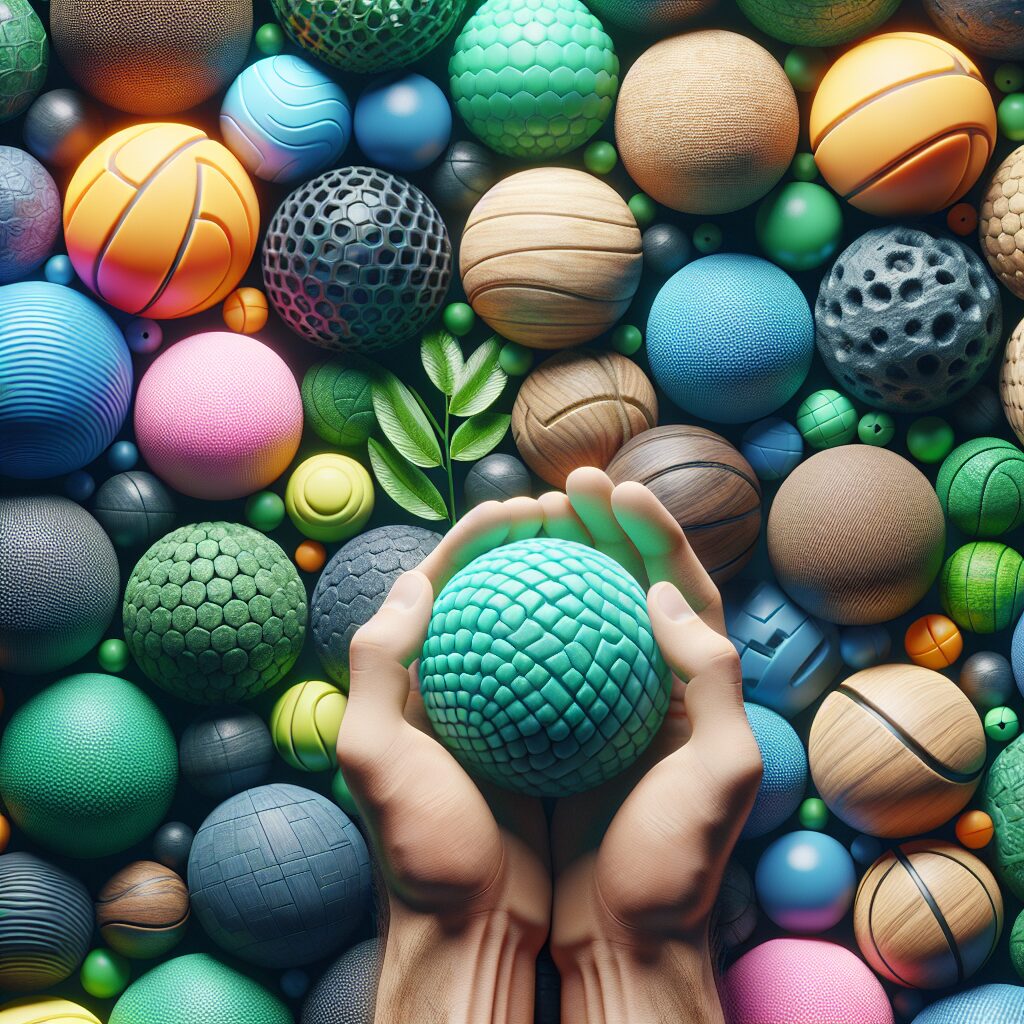

Moving forward, the key takeaways from this article will revolve around the impact of innovative durability testing on ball technology. We will delve into the benefits that this testing methodology brings to athletes, emphasizing the improved performance and safety aspects of durable balls. Moreover, we will discuss the role of durability testing in the development of eco-friendly and sustainable materials for ball production. By providing insights into the cutting-edge techniques and materials used in this field, readers will gain a deeper appreciation for the advancement of ball technology and understand the importance of durability testing in shaping the future of sports equipment.

Key Takeaways

1. Innovative durability testing methods are being developed to advance ball technology in various sports, such as tennis, golf, and soccer.

2. These new testing techniques aim to measure the durability and performance of balls accurately, allowing manufacturers to develop more durable products and athletes to make informed purchasing decisions.

3. One of the key advancements in durability testing is the development of robotic ball launchers that can simulate real-game conditions, providing more accurate and consistent results.

4. Durability testing is not only limited to measuring the physical properties of balls but also includes evaluating the impact of environmental factors, such as temperature, humidity, and UV exposure on ball performance.

5. The use of advanced technologies, like computer simulations and machine learning algorithms, is enabling researchers to gather and analyze vast amounts of data, leading to a deeper understanding of ball behavior and helping manufacturers design better and more durable products.

What is the Impact of Innovative Durability Testing on Advancing Ball Technology?

IntroductionDurability testing has always been crucial in ensuring the quality and performance of various products, and the field of ball technology is no exception. In recent years, innovative approaches to durability testing have emerged, revolutionizing the way balls are developed and enhanced. This article explores the impact of innovative durability testing on advancing ball technology, shedding light on the various techniques and benefits associated with this approach.

The Evolution of Ball Technology

Over the years, ball technology has progressed significantly. From primitive designs made from natural materials to complex structures engineered using innovative techniques, balls have become an essential tool in various sports, industries, and everyday life. However, as the demands and expectations placed on the balls increase, so does the need for robust durability testing methods.

Traditional Durability Testing Methods

Traditional durability testing techniques often focused on measuring durability based on ball weight, circumference, and visual inspection. While these methods provided some insights into the durability of the balls, they lacked precision and failed to capture various factors that affect the performance and longevity of the ball.

The Advantages of Innovative Durability Testing

Innovative durability testing fills the gaps left by traditional techniques, offering a more comprehensive and accurate evaluation of ball performance and durability. By simulating real-world conditions, such as extreme impacts, environmental conditions, and repetitive use, innovative durability testing enables researchers and manufacturers to identify weaknesses, improve designs, and enhance the quality of the balls.

Advanced Testing Technologies

The advancement of technologies, such as high-speed cameras, impact testers, compression sensors, and robotic ball launchers, has revolutionized the field of durability testing. These cutting-edge tools and equipment allow researchers to analyze the behavior of balls under various conditions, capturing crucial data that helps in understanding their strengths and weaknesses.

Industry Applications and Benefits

The impact of innovative durability testing extends beyond the sports industry. Manufacturers in fields like automotive, aerospace, and engineering can also benefit greatly from this testing approach. By subjecting different components, materials, or products to rigorous durability tests, potential flaws and weaknesses can be identified early in the development process, leading to improved overall quality and reliability.

Future Scope and Possibilities

As technology continues to advance, innovative durability testing techniques will further evolve and enhance the development of ball technology. Improved simulation models, specialized sensor technologies, and artificial intelligence algorithms can further refine testing methodologies, allowing for more accurate predictions of product lifespan and robustness.

Conclusion

Innovative durability testing has proven to be a game-changer in advancing ball technology. By enabling precise analysis of ball behavior and performance under a wide range of conditions, this testing approach contributes to the development of more durable, high-performing balls across various industries. Embracing these innovative techniques paves the way for future advancements and ensures that balls continue to meet the ever-increasing expectations of consumers and professionals alike.

Key Considerations for Innovative Durability Testing

1. What are the common challenges faced in traditional durability testing?

2. How does innovative durability testing overcome the limitations of traditional methods?

3. What are the cutting-edge technologies used in innovative durability testing?

4. How can different industries benefit from innovative durability testing approaches?

5. What are the potential future advancements in the field of innovative durability testing?

Remember, the goal of innovative durability testing is to ensure the development of durable, high-quality balls that meet the demands of the ever-evolving market. By embracing innovative testing approaches, manufacturers can stay ahead of the competition and deliver exceptional products.

Frequently Asked Questions

How does durability testing improve ball technology?

Durability testing allows manufacturers to evaluate the strength and longevity of their ball products. By subjecting balls to rigorous testing, they can identify weaknesses and areas for improvement, leading to the development of more durable and resilient balls.

What are the benefits of advancing ball technology?

Advancing ball technology offers numerous benefits. It enhances player performance by improving ball control, accuracy, and consistency. Additionally, it maximizes the longevity of balls, reducing the need for frequent replacements and lowering costs.

What types of durability tests are conducted on balls?

There are various durability tests performed on balls, including stress tests, impact tests, and abrasion tests. These evaluations simulate real-game scenarios and measure how well the balls withstand pressure, collisions, and wear over time.

How do manufacturers ensure accurate and reliable test results?

Manufacturers employ strict protocols and industry standards to ensure accurate and reliable test results. They carefully control testing conditions, follow standardized procedures, and use calibrated equipment. By maintaining consistent testing conditions, manufacturers can obtain reliable data for product improvement.

What factors influence the durability of a ball?

The durability of a ball can be influenced by various factors, such as the quality of materials used, manufacturing techniques, and design elements. Additionally, external factors like playing surfaces, weather conditions, and usage frequency can impact a ball’s durability.

How are innovative materials incorporated into ball technology?

Manufacturers incorporate innovative materials into ball technology through extensive research and development. They explore new materials with enhanced properties, such as improved bounce, durability, and aerodynamics. These materials are then integrated into the design and construction of the ball to enhance its performance and longevity.

What advancements have been made in ball technology recently?

Recent advancements in ball technology include the incorporation of advanced microstructures for better grip and control, the development of specialized coatings for improved resistance to wear and tear, and the utilization of advanced manufacturing techniques to optimize ball performance.

Do advanced ball technologies affect game regulations?

Advanced ball technologies may occasionally influence game regulations. In some cases, regulatory bodies may adapt rules or guidelines to accommodate new technologies. However, the primary focus is always to ensure fair play and maintain a level playing field for all participants.

How long does it typically take to conduct durability tests?

The duration of durability tests varies depending on the specific testing protocol and the type of ball being evaluated. Some tests can be completed within a few hours, while others may require several days or weeks to gather comprehensive data on a ball’s performance and durability.

Are there any drawbacks to advancing ball technology?

While advancing ball technology brings numerous benefits, there can also be drawbacks. Introducing new technologies may lead to increased costs for both manufacturers and consumers. Additionally, players may need some adjustment to adapt to changes in ball characteristics. It is crucial to strike a balance between innovation and maintaining the integrity of the sport.

Final Thoughts on Innovative Durability Testing: Advancing Ball Technology

Through the advancements made in durability testing, ball technology continues to evolve and improve. The ability to analyze and enhance ball durability allows manufacturers to provide athletes and sports enthusiasts with high-quality products that elevate their performance and experience. As technology progresses, we can expect even more innovative breakthroughs in ball design and materials, revolutionizing the way the game is played.

However, it is essential to consider the potential impact of these advancements on the sport as a whole. While advancements in ball technology bring numerous benefits, it is crucial to stay mindful of game regulations and ensure fairness. Striking a balance between innovation and maintaining the integrity of the sport will be instrumental in shaping the future of ball technology.

Durability testing has always been crucial in ensuring the quality and performance of various products, and the field of ball technology is no exception. In recent years, innovative approaches to durability testing have emerged, revolutionizing the way balls are developed and enhanced. This article explores the impact of innovative durability testing on advancing ball technology, shedding light on the various techniques and benefits associated with this approach.

The Evolution of Ball Technology

Over the years, ball technology has progressed significantly. From primitive designs made from natural materials to complex structures engineered using innovative techniques, balls have become an essential tool in various sports, industries, and everyday life. However, as the demands and expectations placed on the balls increase, so does the need for robust durability testing methods.

Traditional Durability Testing Methods

Traditional durability testing techniques often focused on measuring durability based on ball weight, circumference, and visual inspection. While these methods provided some insights into the durability of the balls, they lacked precision and failed to capture various factors that affect the performance and longevity of the ball.

The Advantages of Innovative Durability Testing

Innovative durability testing fills the gaps left by traditional techniques, offering a more comprehensive and accurate evaluation of ball performance and durability. By simulating real-world conditions, such as extreme impacts, environmental conditions, and repetitive use, innovative durability testing enables researchers and manufacturers to identify weaknesses, improve designs, and enhance the quality of the balls.

Advanced Testing Technologies

The advancement of technologies, such as high-speed cameras, impact testers, compression sensors, and robotic ball launchers, has revolutionized the field of durability testing. These cutting-edge tools and equipment allow researchers to analyze the behavior of balls under various conditions, capturing crucial data that helps in understanding their strengths and weaknesses.

Industry Applications and Benefits

The impact of innovative durability testing extends beyond the sports industry. Manufacturers in fields like automotive, aerospace, and engineering can also benefit greatly from this testing approach. By subjecting different components, materials, or products to rigorous durability tests, potential flaws and weaknesses can be identified early in the development process, leading to improved overall quality and reliability.

Future Scope and Possibilities

As technology continues to advance, innovative durability testing techniques will further evolve and enhance the development of ball technology. Improved simulation models, specialized sensor technologies, and artificial intelligence algorithms can further refine testing methodologies, allowing for more accurate predictions of product lifespan and robustness.

Conclusion

Innovative durability testing has proven to be a game-changer in advancing ball technology. By enabling precise analysis of ball behavior and performance under a wide range of conditions, this testing approach contributes to the development of more durable, high-performing balls across various industries. Embracing these innovative techniques paves the way for future advancements and ensures that balls continue to meet the ever-increasing expectations of consumers and professionals alike.

Key Considerations for Innovative Durability Testing

1. What are the common challenges faced in traditional durability testing?

2. How does innovative durability testing overcome the limitations of traditional methods?

3. What are the cutting-edge technologies used in innovative durability testing?

4. How can different industries benefit from innovative durability testing approaches?

5. What are the potential future advancements in the field of innovative durability testing?

Remember, the goal of innovative durability testing is to ensure the development of durable, high-quality balls that meet the demands of the ever-evolving market. By embracing innovative testing approaches, manufacturers can stay ahead of the competition and deliver exceptional products.

Frequently Asked Questions

How does durability testing improve ball technology?

Durability testing allows manufacturers to evaluate the strength and longevity of their ball products. By subjecting balls to rigorous testing, they can identify weaknesses and areas for improvement, leading to the development of more durable and resilient balls.

What are the benefits of advancing ball technology?

Advancing ball technology offers numerous benefits. It enhances player performance by improving ball control, accuracy, and consistency. Additionally, it maximizes the longevity of balls, reducing the need for frequent replacements and lowering costs.

What types of durability tests are conducted on balls?

There are various durability tests performed on balls, including stress tests, impact tests, and abrasion tests. These evaluations simulate real-game scenarios and measure how well the balls withstand pressure, collisions, and wear over time.

How do manufacturers ensure accurate and reliable test results?

Manufacturers employ strict protocols and industry standards to ensure accurate and reliable test results. They carefully control testing conditions, follow standardized procedures, and use calibrated equipment. By maintaining consistent testing conditions, manufacturers can obtain reliable data for product improvement.

What factors influence the durability of a ball?

The durability of a ball can be influenced by various factors, such as the quality of materials used, manufacturing techniques, and design elements. Additionally, external factors like playing surfaces, weather conditions, and usage frequency can impact a ball’s durability.

How are innovative materials incorporated into ball technology?

Manufacturers incorporate innovative materials into ball technology through extensive research and development. They explore new materials with enhanced properties, such as improved bounce, durability, and aerodynamics. These materials are then integrated into the design and construction of the ball to enhance its performance and longevity.

What advancements have been made in ball technology recently?

Recent advancements in ball technology include the incorporation of advanced microstructures for better grip and control, the development of specialized coatings for improved resistance to wear and tear, and the utilization of advanced manufacturing techniques to optimize ball performance.

Do advanced ball technologies affect game regulations?

Advanced ball technologies may occasionally influence game regulations. In some cases, regulatory bodies may adapt rules or guidelines to accommodate new technologies. However, the primary focus is always to ensure fair play and maintain a level playing field for all participants.

How long does it typically take to conduct durability tests?

The duration of durability tests varies depending on the specific testing protocol and the type of ball being evaluated. Some tests can be completed within a few hours, while others may require several days or weeks to gather comprehensive data on a ball’s performance and durability.

Are there any drawbacks to advancing ball technology?

While advancing ball technology brings numerous benefits, there can also be drawbacks. Introducing new technologies may lead to increased costs for both manufacturers and consumers. Additionally, players may need some adjustment to adapt to changes in ball characteristics. It is crucial to strike a balance between innovation and maintaining the integrity of the sport.

Final Thoughts on Innovative Durability Testing: Advancing Ball Technology

Through the advancements made in durability testing, ball technology continues to evolve and improve. The ability to analyze and enhance ball durability allows manufacturers to provide athletes and sports enthusiasts with high-quality products that elevate their performance and experience. As technology progresses, we can expect even more innovative breakthroughs in ball design and materials, revolutionizing the way the game is played.

However, it is essential to consider the potential impact of these advancements on the sport as a whole. While advancements in ball technology bring numerous benefits, it is crucial to stay mindful of game regulations and ensure fairness. Striking a balance between innovation and maintaining the integrity of the sport will be instrumental in shaping the future of ball technology.