Rubber Blend Versatility: Meeting Diverse Needs

Rubber blends, also known as rubber compounds or rubber mixtures, refer to the combination of two or more types of rubber materials. This blending process allows for the creation of unique rubber properties that can meet diverse needs across various industries. With its wide range of applications, rubber blend versatility has become a crucial aspect in the manufacturing sector, bridging the gap between different product requirements.

The versatility of rubber blends lies in their ability to exhibit specific impacts or unique features that cannot be achieved by using a single type of rubber alone. By combining different rubber materials, manufacturers can create blends that possess desired characteristics such as improved durability, enhanced flexibility, increased resistance to wear and tear, and superior heat or cold resistance. These blended rubbers can be tailored to meet the specific requirements of different industries, including automotive, construction, electronics, and medical.

In the following sections, we will explore the key takeaways related to rubber blend versatility. We will delve deeper into the various industries that benefit from these blends, highlighting specific applications and the advantages they bring. Additionally, we will discuss the manufacturing process involved in creating rubber blends and the considerations that need to be taken into account to ensure the desired properties are achieved. So, let’s dive into the world of rubber blend versatility and discover how it continues to meet diverse needs in today’s ever-evolving market.

Key Takeaways

1. Rubber blend is a versatile material that can be customized to meet various needs and specifications in numerous industries, including automotive, construction, and healthcare.

2. The flexibility and durability of rubber blends make them ideal for applications requiring resistance to extreme temperatures, water, oil, and chemicals.

3. Recent advancements in technology and manufacturing processes have allowed for the development of rubber blends with enhanced properties such as improved strength, reduced weight, and better environmental sustainability.

4. Rubber blends have proven to be cost-effective solutions for many industries, as they can be tailored to match specific performance requirements, reducing the need for multiple materials or complex assembly processes.

5. The ongoing research and development in rubber blend formulations and processing techniques ensure that their versatility and performance will continue to evolve, meeting the ever-changing demands of diverse industries.

Which Rubber Blends Offer Versatility to Meet Diverse Needs?

Understanding the Importance of Rubber Blend Versatility

Rubber blends play a crucial role in various industries by offering versatility to meet diverse needs. These blends are specifically designed to combine the unique properties of different rubbers, creating a material that can perform optimally in a wide range of applications. Whether it’s automotive, construction, or consumer goods, rubber blends offer enhanced durability, resilience, and flexibility.

Factors Influencing Rubber Blend Versatility

Several factors contribute to the versatility of rubber blends:

- Type of Rubber: Each type of rubber brings distinct characteristics to the blend. Natural rubber provides high elasticity, synthetic rubbers like SBR offer better durability, while EPDM excels in weather resistance.

- Blend Composition: The proportions and combination of different rubber types affect the resulting blend’s performance. By adjusting the ratios, manufacturers can alter the blend’s properties to match specific application requirements.

- Additives: Introducing additives, such as carbon black or silica, enhances the blend’s strength, abrasion resistance, and heat resistance. Additives can also improve properties like electrical conductivity or chemical resistance, making rubber blends more versatile.

Applications of Rubber Blend Versatility

The versatility of rubber blends enables their use in a multitude of applications:

1. Automotive Industry

Rubber blends find extensive use in automobile manufacturing. They are used in tire production, where different rubber types are combined to achieve optimal grip, fuel efficiency, and tread wear resistance. Rubber blends are also utilized in various automotive components, such as seals, gaskets, hoses, and vibration isolators.

2. Construction Sector

The construction industry benefits from the versatility of rubber blends through their inclusion in materials used for roofing, flooring, insulation, and sealants. By incorporating rubber blends, construction materials gain enhanced weather resistance, impact absorption, and longevity.

3. Consumer Goods

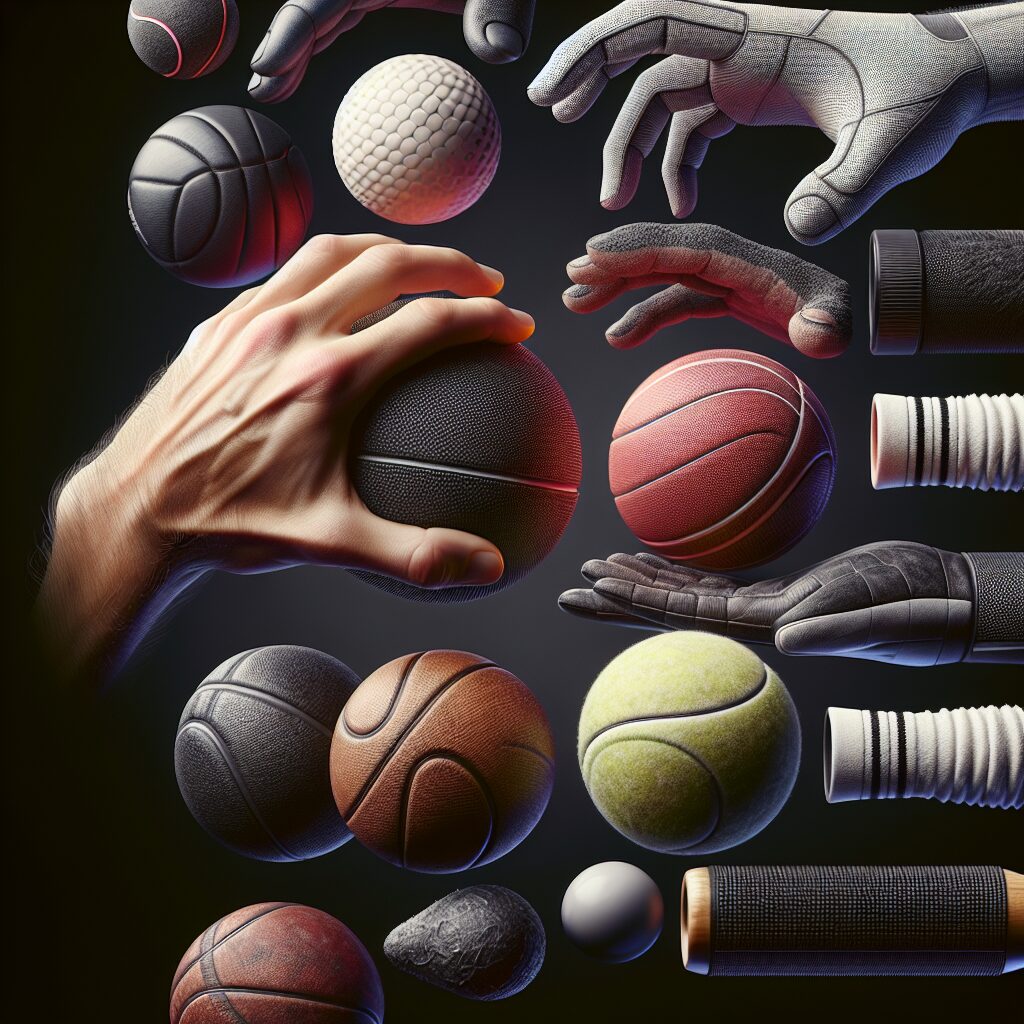

From sporting equipment like basketballs and tennis balls to household products like gloves, mats, and toys, rubber blends play a significant role in manufacturing consumer goods. These blends offer durability, comfort, and safety while meeting specific performance requirements set by different consumer products.

4. Industrial Applications

Industries such as oil and gas, mining, and manufacturing rely on rubber blends for various applications. From conveyor belts and rollers to hydraulic seals and vibration mounts, the versatility of rubber blends ensures extended service life, chemical resistance, and reliability in demanding industrial environments.

Tips for Choosing the Right Rubber Blend

If you are considering incorporating rubber blends into your application, here are some essential tips to guide you:

- Define Your Requirements: Clearly identify the specific performance requirements for your application, including factors like temperature, pressure, chemical exposure, and wear resistance.

- Consult Experts: Seek advice from rubber engineers and suppliers who can help you select the best rubber blend composition and additives based on your requirements.

- Consider Cost: Balance the performance benefits with the overall cost of the rubber blend. Evaluate long-term savings due to increased durability and reliability.

- Test and Evaluate: Conduct thorough testing and evaluation of the chosen rubber blend in your application to ensure it meets your desired performance criteria.

- Maintain Proper Care: Follow recommended maintenance and care practices to ensure the longevity and optimal performance of the rubber blend.

By understanding the versatility offered by rubber blends and making informed decisions, you can meet diverse needs and achieve optimal performance in your specific applications.

Frequently Asked Questions

1. What is rubber blend versatility?

Rubber blend versatility refers to the ability of rubber blends to meet diverse needs and perform various functions due to their unique properties and compositions.

2. What are the key properties of rubber blends?

Rubber blends typically exhibit excellent elasticity, durability, resistance to wear and tear, as well as resistance to chemicals, heat, and cold.

3. What industries benefit from rubber blend versatility?

Various industries benefit from rubber blend versatility, including automotive, construction, manufacturing, healthcare, and consumer goods sectors.

4. How are rubber blends different from natural rubber?

Rubber blends are synthetic materials created by combining natural rubber with other additives or synthetic rubbers, which can enhance specific properties and tailor the blend for different applications.

5. What are some common applications of rubber blends?

Rubber blends find applications in tires, seals and gaskets, hoses, conveyor belts, footwear, coatings, adhesives, and many other products and components.

6. How can rubber blend versatility contribute to sustainability?

By using rubber blends, manufacturers can optimize material usage, enhance product durability, improve energy efficiency, and reduce waste, thus contributing to sustainable practices.

7. Are there any limitations or drawbacks to using rubber blends?

Though rubber blends offer numerous advantages, they may have certain limitations in extreme conditions, such as extreme temperatures or exposure to certain chemicals that can degrade the material.

8. How can one determine the right rubber blend for their specific needs?

Determining the right rubber blend requires considering factors like the intended application, environmental conditions, required durability, chemical compatibility, and specific performance characteristics. Consulting with rubber blend experts is advised.

9. Can rubber blends be customized for specific requirements?

Yes, rubber blends offer a high level of customization. Manufacturers can adjust the blend composition, additives, and processing methods to meet specific performance requirements or to achieve desired characteristics.

10. Are rubber blends cost-effective compared to other materials?

While the cost of rubber blends can vary depending on the specific blend and application, they are generally considered cost-effective due to their durability, long lifespan, and ability to be optimized for specific needs, resulting in reduced maintenance and replacement costs.

Final Thoughts

The versatility of rubber blends offers endless possibilities and solutions for diverse needs across various industries. From providing reliable performance in tire manufacturing to enabling efficient seal production in healthcare, rubber blends have become indispensable components of modern products.

As technology continues to advance, the potential for further innovation and enhancements in rubber blend versatility is immense. With ongoing research and development, we can expect even more tailored blends and improved sustainability in the future. The rubber blend industry will undoubtedly continue to evolve and shape our world, meeting the ever-changing needs of society.