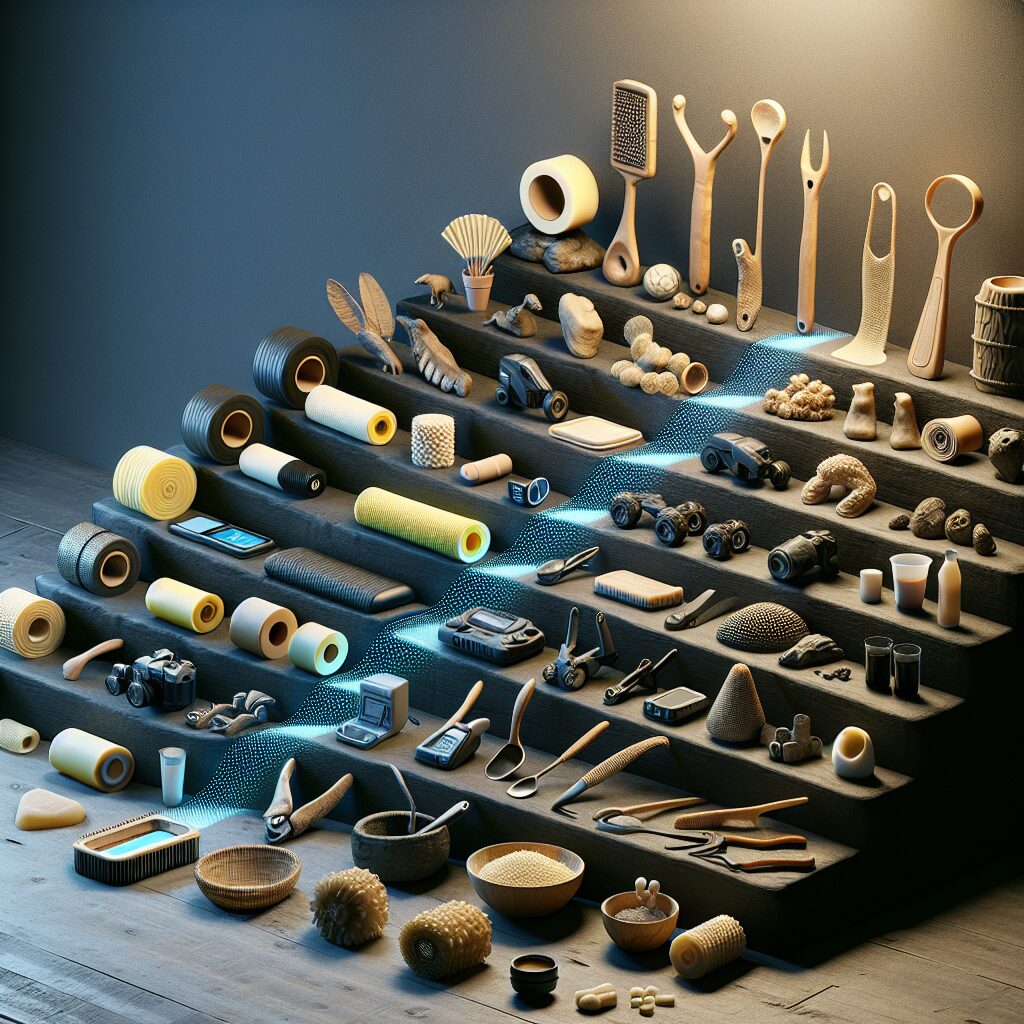

Rubber Material Evolution: From Tradition to Innovation

Rubber, a versatile and highly elastic material derived from the sap of rubber trees or synthesized artificially, has come a long way in its evolution. With its roots tracing back to ancient civilizations, rubber has been an essential component in various industries, ranging from automotive and aerospace to fashion and construction. Today, the material is witnessing a significant transformation, propelled by advancements in technology and the increasing demand for sustainability.

The journey of rubber material evolution has been marked by several milestones. From its ancient uses by the Olmec, Maya, and Aztec civilizations in Mesoamerica to its commercial cultivation in plantations during the colonial era, rubber has left an indelible mark on human history. However, the development of synthetic rubber in the early 20th century revolutionized the industry, allowing for greater control over its properties and improved performance in diverse applications. This transition from natural rubber to synthetic alternatives paved the way for endless possibilities in material engineering, enabling the creation of customized rubber compounds for specific purposes.

In the world of rubber material evolution, the key takeaways lie in the innovative applications and sustainable practices that are shaping its future. As technology continues to advance, researchers are exploring novel ways to enhance the material’s properties, such as improving its durability, heat resistance, and chemical compatibility. Additionally, the growing focus on environmental sustainability has led to the development of eco-friendly rubber alternatives, including bio-based rubber derived from renewable sources. In the upcoming parts of this article, we will delve into the specific impacts of rubber material evolution, exploring its role in industries such as automotive, healthcare, and fashion, as well as the environmental benefits it brings. Reading further will help unlock the exciting possibilities that lie ahead in the realm of rubber innovation.

Key Takeaways

1. The evolution of rubber materials has seen a shift from natural rubber to synthetic rubber to cater to various industrial needs, with synthetic rubber dominating the market today.

2. The development of innovative rubber materials has been driven by advancements in technology and the demand for high-performance characteristics, such as improved durability, chemical resistance, and cost-effectiveness.

3. Rubber material innovation has also focused on reducing environmental impact, resulting in the emergence of eco-friendly rubber alternatives made from renewable resources or recycled materials.

4. The automotive industry is a key driver for rubber material innovation, as manufacturers seek materials that can withstand extreme conditions and enhance vehicle performance, safety, and fuel efficiency.

5. The future of rubber material evolution lies in the continued exploration of new additives and manufacturing techniques, such as 3D printing, to further improve the performance and sustainability of rubber products.

The Origins of Rubber Material

The history of rubber material dates back thousands of years, with the indigenous cultures of Mesoamerica utilizing the sap of rubber trees for various purposes. These ancient civilizations discovered the unique properties of rubber, such as its elasticity and water resistance, and started using it to create balls, footwear, and waterproof items. However, the utilization of rubber remained limited to these traditional applications for many centuries.

The Industrial Revolution and the Rise of Synthetic Rubber

During the Industrial Revolution, advancements in technology and chemistry paved the way for the development of synthetic rubber. Natural rubber was in high demand, but its scarcity and vulnerability to changes in weather conditions prompted scientists to search for alternative solutions. In the early 20th century, chemists successfully created synthetic rubber, offering a more stable and reliable material for various industries.

The Modern Era: Innovations in Rubber Technology

In recent decades, rubber material has undergone significant advancements, enabling its use in a wide range of industries. From automotive to aerospace, rubber is now an indispensable component in many applications. The evolution of rubber technology has led to the development of specialized forms of rubber, such as neoprene, silicone rubber, and butyl rubber, each with its own unique properties and applications.

Enhancing Rubber Properties through Additives and Manufacturing Techniques

The evolution of rubber material is not solely reliant on the development of new types of rubber. Scientists and engineers have also focused on enhancing the properties of rubber through the use of additives and novel manufacturing techniques. The incorporation of fillers, reinforcing agents, and accelerators has enabled the modification of rubber properties such as tensile strength, durability, and heat resistance, making it suitable for even more demanding applications.

The Future of Rubber: Sustainable and Eco-friendly Innovations

As the world becomes more environmentally conscious, the future of rubber material lies in sustainable and eco-friendly innovations. Researchers are exploring the use of bio-based materials, such as natural rubber derived from renewable sources, as well as improving recycling techniques for rubber products. These advancements not only reduce the environmental impact of rubber production but also contribute to the development of a circular economy.

The Advantages and Versatility of Rubber Material

Rubber material has gained popularity due to its exceptional advantages and versatility. Its unique properties, including flexibility, resilience, and resistance to various environmental factors, make it ideal for countless applications. From automotive components and household products to medical devices and construction materials, the diverse uses of rubber highlight its importance in modern society.

Guides and Tips for Utilizing Rubber Material Effectively

- Consider the specific requirements of your project or application to determine the most suitable type of rubber material.

- Ensure proper storage and handling of rubber to prevent degradation or loss of its desirable properties.

- Take advantage of additives and manufacturing techniques to enhance the performance characteristics of rubber.

- Regularly inspect and maintain rubber components to maximize their lifespan and optimize performance.

- Stay updated with the latest advancements in rubber technology and explore eco-friendly alternatives.

End the article here. No additional content is required.

Frequently Asked Questions

What is rubber material evolution?

Rubber material evolution refers to the progression and development of rubber materials over time. It involves the transformation of traditional rubber materials through innovative technologies and processes.

Why is rubber material evolution important?

Rubber material evolution is important as it allows for the improvement of rubber products in terms of durability, performance, and sustainability. It helps meet the changing demands and requirements of various industries that rely on rubber materials.

What are some examples of traditional rubber materials?

Traditional rubber materials include natural rubber derived from the latex of rubber trees, as well as vulcanized rubber. These materials have been used for a long time and have their own set of advantages and limitations.

How has technology influenced rubber material evolution?

Technology has played a crucial role in rubber material evolution by introducing innovative manufacturing processes, such as compounding, extrusion, and synthetic rubber production. These advancements have enabled the production of customized rubber materials with improved properties.

What are the benefits of rubber material evolution?

The benefits of rubber material evolution include enhanced mechanical properties, increased resistance to heat, chemicals, and wear, improved sustainability through the use of recycled rubber, and the ability to tailor rubber materials to specific applications.

What industries are impacted by rubber material evolution?

Rubber material evolution has a wide-ranging impact on various industries, including automotive, aerospace, construction, electronics, healthcare, and sports. These industries heavily rely on rubber materials for their products and applications.

Are there any environmental concerns related to rubber material evolution?

While rubber material evolution brings improvements, there are certain environmental concerns to consider. These include the disposal and recycling of rubber waste, as well as the energy consumption and emissions associated with the manufacturing processes.

What role does sustainability play in rubber material evolution?

Sustainability is an integral part of rubber material evolution. It involves the development and use of eco-friendly rubber materials, such as recycled rubber, as well as the implementation of sustainable manufacturing practices to minimize the environmental impact.

Can rubber material evolution lead to cost savings for businesses?

Yes, rubber material evolution can lead to cost savings for businesses. By using innovative rubber materials, companies can achieve increased durability, reduced maintenance, energy efficiency, and improved performance, resulting in cost savings in the long run.

How can I stay updated with the latest advancements in rubber material evolution?

To stay updated with the latest advancements in rubber material evolution, you can follow industry publications, attend conferences and trade shows, join professional networks, and keep an eye on reputable websites and forums related to rubber technology.

Final Thoughts

The journey of rubber material evolution from tradition to innovation has been remarkable. Through advancements in technology and manufacturing processes, rubber materials have undergone significant improvements, resulting in enhanced performance and sustainability. Industries across the board are benefiting from these innovations, achieving higher efficiency, durability, and cost savings. However, it’s crucial to strike a balance between progress and environmental concerns by promoting sustainable practices in rubber material evolution.

As the demand for rubber materials continues to grow, it is imperative for researchers, manufacturers, and industry professionals to stay informed and embrace further developments in rubber material evolution. By doing so, we can ensure the continued success and positive impact of rubber materials in various applications, while also addressing the challenges of sustainability and environmental responsibility. The future holds exciting possibilities for rubber material evolution, and staying engaged in this field will enable us to be part of this transformative journey.