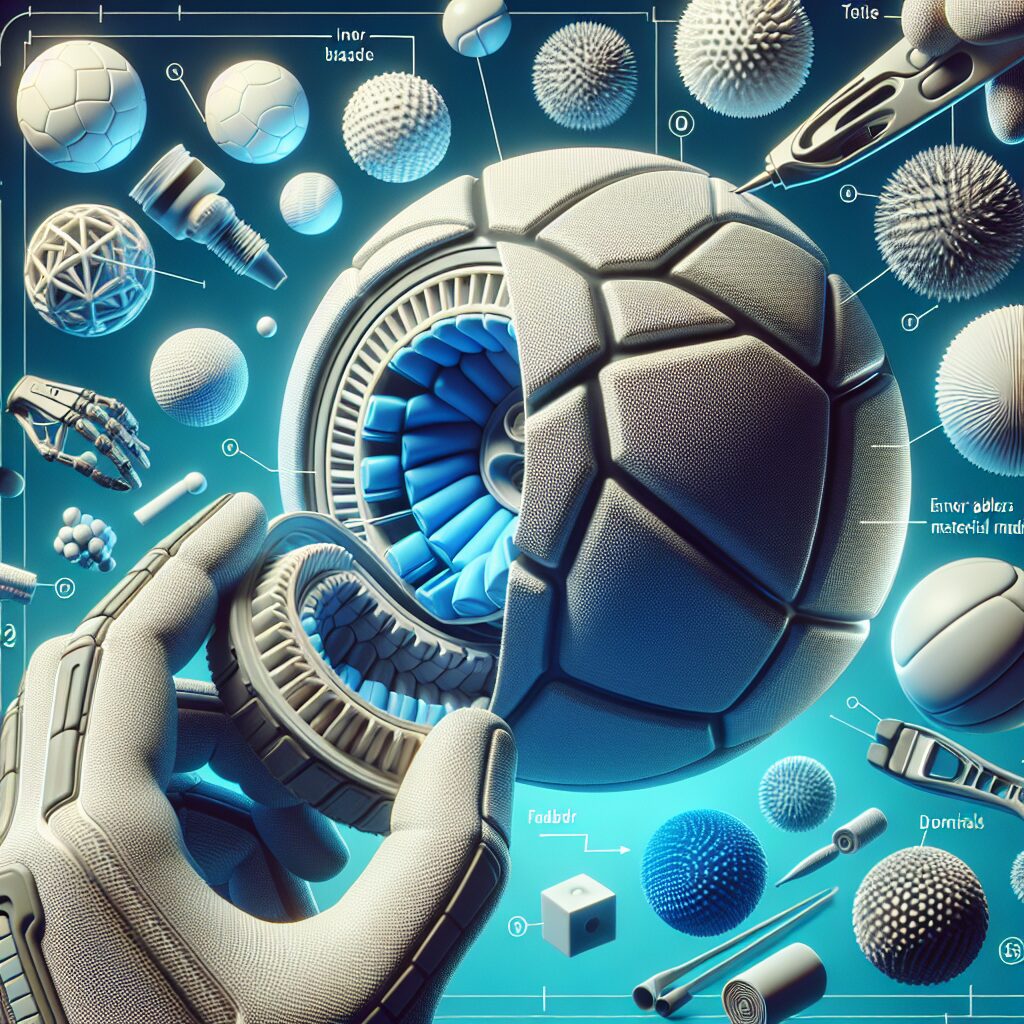

In the world of sports ball manufacturing, one crucial component that often goes unnoticed is the inner bladder material. The inner bladder acts as the heart of the ball, providing it with the necessary shape, durability, and performance. But what exactly is an inner bladder material? Well, it refers to the material that is used to construct the inner layer of the ball, which is responsible for maintaining the ball’s shape and retaining air pressure. This often overlooked aspect of sports ball manufacturing has a significant impact on the overall quality and performance of the ball.

When it comes to inner bladder materials, various factors come into play. The choice of material affects the ball’s responsiveness, bounce, trajectory, and overall feel. For instance, in soccer ball manufacturing, manufacturers commonly use latex or butyl bladders. Latex bladders are known for their superior responsiveness and touch, making them the preferred choice for professional players. On the other hand, butyl bladders are renowned for their excellent air retention properties, ensuring optimal pressure throughout a game or match. In contrast, basketball manufacturers often opt for rubber bladders due to their elasticity and ability to withstand intense impacts and rough handling on the court.

Now that we understand the importance of inner bladder materials in sports ball manufacturing, let’s delve into the key takeaways. In the following sections, we will explore the different types of inner bladder materials used in various sports balls and their specific impacts on the ball’s performance. We will also discuss the advantages and disadvantages of each material, providing valuable insights for both manufacturers and players alike. So, grab a seat and join us on this insightful journey into the world of inner bladder materials in sports ball manufacturing.

Key Takeaways

1. Different inner bladder materials have a significant impact on the performance and durability of sports balls.

2. The choice of inner bladder material depends on factors such as cost, performance requirements, and manufacturing process.

3. Natural rubber is commonly used due to its excellent elasticity and air retention properties.

4. Synthetic materials like polyurethane are gaining popularity due to their durability and increased control over performance characteristics.

5. Ongoing research aims to develop new inner bladder materials that offer improved performance, durability, and environmental sustainability.

What are the Best Inner Bladder Materials for Sports Ball Manufacturing?

Importance of Inner Bladder Materials in Sports Ball Manufacturing

The inner bladder of a sports ball plays a crucial role in determining the performance, durability, and overall quality of the ball. The choice of materials for the inner bladder can greatly impact factors such as air retention, bounce, responsiveness, and control. In sports ball manufacturing, it is essential to understand and utilize the most suitable materials to ensure the production of superior quality balls.

Natural Rubber

Natural rubber is a widely used material for the inner bladder in sports ball manufacturing. It offers excellent elasticity, durability, and rebound properties. The unique molecular structure of natural rubber allows it to retain air efficiently, resulting in better ball pressure. Moreover, natural rubber is highly resistant to wear and tear, making it suitable for high-impact sports like basketball and soccer.

Synthetic Rubber

Synthetic rubber, typically made from petroleum-based polymers, is another popular choice for the inner bladder in sports ball manufacturing. It offers similar characteristics to natural rubber, such as good elasticity and air retention, but often at a lower cost. Synthetic rubber can be engineered to meet specific performance requirements and can be an ideal choice for various sports, including tennis and rugby.

Polyurethane (PU)

Polyurethane (PU) is a versatile material that has gained popularity in sports ball manufacturing. It offers exceptional durability, rebound properties, and moisture resistance. PU inner bladders provide consistent bounce and excellent air retention, making them suitable for balls used in sports like volleyball and handball. Additionally, PU can be molded into complex shapes, allowing manufacturers to create balls with specific designs and performance features.

Butyl Rubber

Butyl rubber is often used as a lining material for the inner bladder in sports ball manufacturing. It offers excellent air retention properties, ensuring the ball maintains optimal pressure for an extended period. Butyl rubber-lined bladders are commonly found in soccer balls and basketballs, as they provide consistent performance and reduce the need for frequent inflation.

Multi-Layered Bladders

Some sports balls utilize multi-layered bladders, combining different materials to achieve specific performance attributes. For example, a ball may feature a layer of natural rubber for enhanced bounce and a butyl rubber lining for improved air retention. Multi-layered bladders allow manufacturers to optimize the performance of the ball based on the requirements of different sports.

Conclusion

The choice of inner bladder materials is vital in sports ball manufacturing to ensure the production of high-quality balls that meet the demands of athletes. Whether it’s natural rubber, synthetic rubber, polyurethane, butyl rubber, or a combination of materials, each has its own strengths and benefits. By carefully selecting and utilizing the appropriate inner bladder materials, manufacturers can deliver sports balls that offer superior performance, durability, and playability.

Guides and Tips for Choosing Inner Bladder Materials

- Consider the specific performance requirements of the sport when selecting inner bladder materials.

- Evaluate and compare the elasticity, durability, rebound properties, and air retention capabilities of different materials.

- Understand the cost implications of various inner bladder materials and weigh them against desired performance characteristics.

- Explore the possibility of using multi-layered bladders to optimize the ball’s performance for different sports.

- Stay updated with advancements in material technologies to identify new options and improve manufacturing processes.

Frequently Asked Questions

1. What are inner bladder materials in sports ball manufacturing?

Inner bladder materials refer to the materials used to create the inner bladder component of sports balls. This bladder holds the air and gives the ball its shape and bounce.

2. What are the commonly used materials for the inner bladder in sports balls?

The most commonly used materials for inner bladders in sports balls are butyl rubber, latex rubber, and synthetic materials such as polyurethane. Each material offers different characteristics and performance qualities.

3. How does the choice of inner bladder material affect the performance of the sports ball?

The choice of inner bladder material can have a significant impact on the performance of the sports ball. Different materials have varying levels of air retention, elasticity, and durability, which can influence factors such as the ball’s bounce, overall feel, and longevity.

4. Which inner bladder material is best for soccer balls?

For soccer balls, butyl rubber is commonly used as the inner bladder material due to its excellent air retention capabilities. It helps maintain the ball’s optimal shape and size, ensuring consistent performance throughout the game.

5. Are there any eco-friendly options for inner bladder materials?

Yes, there are eco-friendly alternatives available for inner bladder materials. Some manufacturers are increasingly using recycled materials, natural rubber, or other sustainable alternatives to reduce the environmental impact of sports ball manufacturing.

6. Can the inner bladder material affect the weight of the sports ball?

Yes, the choice of inner bladder material can influence the weight of the sports ball. Different materials have different densities, which can impact the overall weight of the ball. Manufacturers carefully consider the desired weight-to-performance ratio when selecting bladder materials.

7. What factors should be considered when choosing the inner bladder material?

When choosing the inner bladder material, factors such as air retention, elasticity, durability, weight, and environmental impact should be considered. The intended sport, playing conditions, and desired performance characteristics also play a crucial role in the selection process.

8. How does the inner bladder material affect the ball’s feel and touch?

The inner bladder material can significantly impact the ball’s feel and touch. Materials with higher elasticity can provide a softer feel and better control, whereas less elastic materials may result in a firmer touch and more responsiveness.

9. Are inner bladder materials interchangeable between different sports balls?

While some inner bladder materials may be interchangeable between different sports balls, it is essential to consider the specific performance requirements of each sport. Different sports have varying demands for factors like bounce, weight, and responsiveness, which may necessitate the use of specific bladder materials.

10. How can the choice of inner bladder material affect the price of the sports ball?

The choice of inner bladder material can impact the price of the sports ball. Materials that offer superior performance or are eco-friendly may be more expensive. Additionally, the availability and production costs of certain materials can also contribute to variations in price.

Final Thoughts

Inner bladder materials play a crucial role in the manufacturing of sports balls, impacting their performance and overall quality. Manufacturers constantly strive to find the perfect balance between air retention, elasticity, durability, and environmental sustainability. By understanding the benefits and characteristics of different bladder materials, both athletes and consumers can make informed decisions when choosing sports balls that meet their specific needs.

As technology advances and sustainable practices become more prevalent, we can expect continuous innovation and improvement in inner bladder materials. By finding eco-friendly alternatives and enhancing performance attributes, the sports ball manufacturing industry can not only provide exceptional sporting experiences but also contribute to a greener future. It’s essential for manufacturers, athletes, and individuals involved in sports to stay informed and support initiatives that prioritize both performance and sustainability in the materials used for sports ball manufacturing.