Inside baseballs: Core Materials and Performance

Baseball, known as America’s pastime, is a sport that has captivated millions of fans around the world for decades. While the game itself is filled with excitement and strategy, there is much more to this beloved sport than meets the eye. One crucial aspect that often goes unnoticed is the core material of a baseball and its impact on performance. Did you know that the core of a baseball plays a significant role in how the ball travels through the air and interacts with the bat? Understanding the composition and properties of baseball cores provides fascinating insights into the physics behind the game.

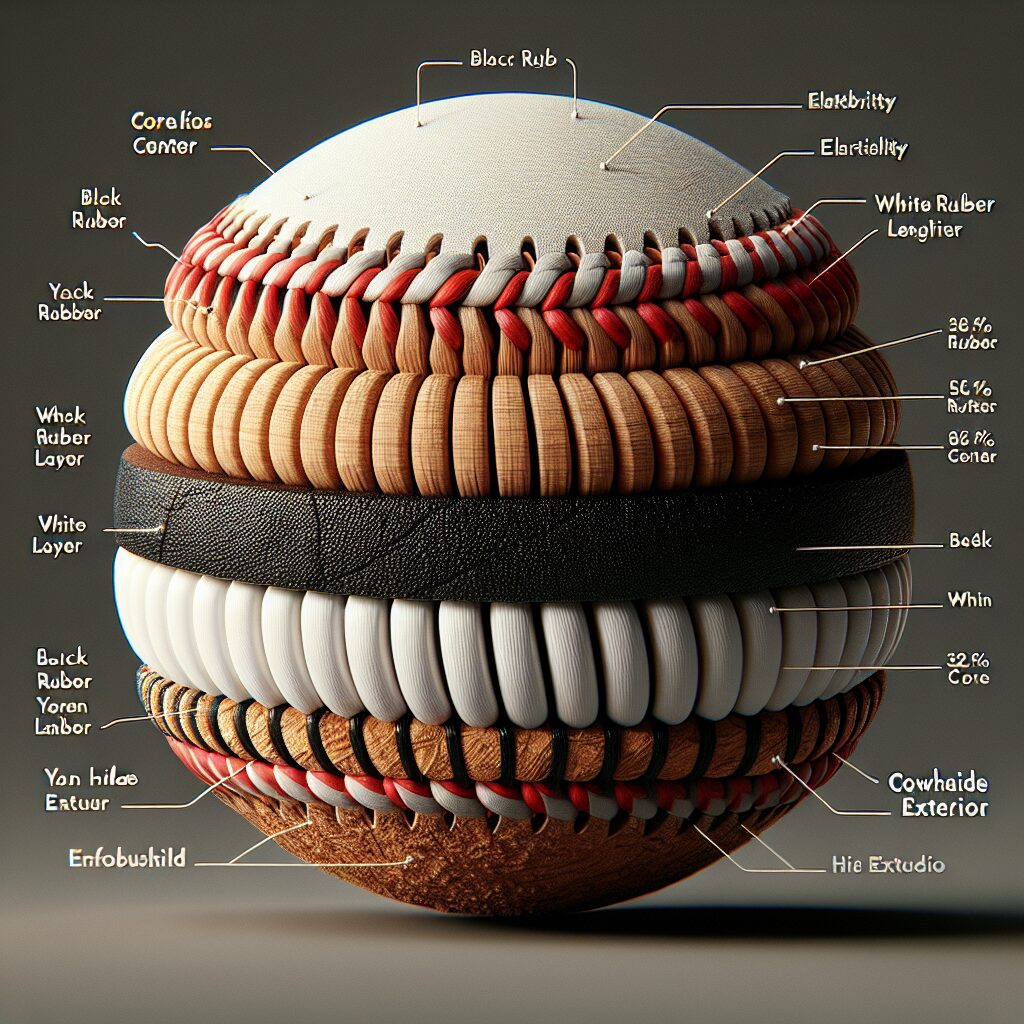

The core material of a baseball is primarily responsible for its performance characteristics, such as its velocity, distance, and how it responds to contact with the bat. Most baseball cores are made with a rubber or cork center, encapsulated by layers of tightly wound yarn and covered with leather. The density and resilience of the core material affect how the ball bounces off the bat and how much distance it can cover when hit. Additionally, the core material can impact the ball’s ability to maintain its shape and stability during gameplay, ultimately affecting the trajectory and accuracy of a pitch.

Now that we understand the significance of the core material in a baseball, let’s delve into the key takeaways related to this topic. In the upcoming sections, we will explore the different types of core materials used in baseball manufacturing, their unique features, and the implications they have on the overall performance of the ball. We will also uncover how advancements in technology have shaped the evolution of core materials over the years, leading to more exceptional gameplay experiences. So, let’s dive in and unravel the secrets behind what truly powers the baseball on the field.

Key Takeaways

1. Core materials play a crucial role in determining the performance and durability of baseballs.

2. The composition and construction of the core significantly impact the ball’s flight characteristics, such as velocity and spin rate.

3. Cork and rubber are common core materials used in baseballs, with the former known for its ability to maintain ball shape and the latter for its durability.

4. The size and density of the core materials can also affect the ball’s performance, with larger cores leading to decreased velocity and increased drag.

5. As the design and technology behind baseballs continue to evolve, finding the optimal core material and construction remains an ongoing challenge for manufacturers and league officials.

What are the Core Materials and Performance of Inside Baseballs?

The Importance of Core Materials in Baseballs

When it comes to baseballs, the core material plays a crucial role in defining their performance. The core, typically made of a combination of rubber and cork, affects the ball’s weight, resilience, and overall behavior during play. Understanding these core materials is vital for players, coaches, and enthusiasts to comprehend the dynamics of the game.

The Influence of Core Materials on Ball Weight

The core material directly impacts the weight of baseballs. By adjusting the composition, manufacturers can control the ball’s weight to meet specific league regulations. This ensures fair play and consistency throughout the game. The combination of rubber and cork allows for precise weight distribution, allowing pitchers to throw accurately and batters to hit with confidence.

Resilience and Responsiveness of Core Materials

The resilience of core materials significantly affects the ball’s behavior on impact. Rubber and cork cores provide a balanced level of bounce and compression, resulting in the desired performance characteristics. This enables pitchers to throw pitches with various spin rates, while batters can anticipate the ball’s behavior off the bat. The core materials also contribute to the overall durability of the baseball, ensuring it can withstand multiple games before needing replacement.

Performance Factors Affected by Core Materials

The core material directly influences several performance factors of baseballs. These include the ball’s velocity, distance traveled, and trajectory when it is hit. A well-designed core material allows for optimal energy transfer upon contact, leading to impressive shots and exciting plays. Players can train and strategize based on their understanding of how baseballs will behave in different game situations.

The Evolution of Core Materials in Baseballs

Over the years, core materials in baseballs have evolved to enhance performance and maintain fairness in the game. Manufacturers have experimented with different combinations of rubber, cork, and even synthetic materials to achieve the desired effects. By studying and analyzing the performance of these newly developed core materials, researchers and designers continuously strive to meet the evolving demands of modern baseball.

Proper Care and Maintenance for Long-lasting Performance

To ensure consistent performance and durability of baseballs, proper care and maintenance are essential. Here are some tips:

- Store baseballs in a cool and dry place to prevent warping or damage.

- Regularly clean baseballs using mild soap and water to remove dirt and grime.

- Inspect baseballs for any signs of wear or damage before each game or practice session.

- Rotate baseballs during play to distribute wear evenly across the entire collection.

- Replace baseballs as needed, ensuring all players have access to high-quality equipment.

How to Choose the Right Baseball Core Material?

When selecting baseballs for your team or personal use, consider the following factors:

- League regulations and requirements regarding core material and weight.

- Your playing style and preferences for ball responsiveness.

- The expected playing conditions, including temperature and humidity.

- Budget constraints, as different core materials may vary in cost.

- Consulting with experienced players or coaches for their recommendations.

Conclusion

In conclusion, understanding the core materials and their impact on the performance of inside baseballs is crucial for anyone involved in the game. By comprehending how core materials affect weight, resilience, and various performance factors, players and coaches can make informed decisions and optimize their gameplay. Proper maintenance and choosing the right core material can ensure long-lasting performance and enjoyable baseball experiences.

Frequently Asked Questions

Can the core material of a baseball affect its performance?

Yes, the core material of a baseball plays a crucial role in determining its performance. Different core materials can impact factors such as the ball’s flight trajectory, speed, and bounce. It is important for manufacturers to carefully select the core material to ensure optimal performance on the field.

What are the most common core materials used in baseballs?

The most common core materials used in baseballs are cork and rubber. These materials are known for their ability to provide a good balance of performance characteristics. Cork cores offer durability and resilience, while rubber cores offer a softer feel and enhanced safety.

Do baseballs with a cork core perform better than those with a rubber core?

Baseballs with a cork core are generally associated with a higher level of performance. Cork cores provide better energy transfer, resulting in a livelier ball flight and increased distance when hit. However, rubber core baseballs have their advantages, especially in terms of safety and softer impacts during play.

What is the significance of the surrounding materials around the core in baseballs?

The surrounding materials, such as the yarn and leather cover, play a crucial role in shaping the overall performance of a baseball. Yarn windings provide structure and stability to the ball, while the leather cover affects the grip, flight, and durability. All these components work together to optimize the ball’s performance.

How does the density of the core material affect baseball performance?

The density of the core material directly affects the ball’s weight and its ability to transfer energy upon impact. A denser core material will result in a heavier ball with higher momentum, potentially leading to increased ball speed and distance when hit. However, finding the right balance is important to ensure the ball is not too heavy or too light for optimal play.

Are there any regulations or standards governing the core materials used in official baseballs?

Yes, official baseballs used in professional leagues and tournaments must adhere to specific regulations and standards set by the respective governing bodies. These regulations cover aspects such as core material composition, size, weight, and performance characteristics to ensure a fair and consistent gameplay experience.

What are the advantages of using synthetic core materials in baseballs?

Synthetic core materials offer several advantages in baseball manufacturing. They can provide consistent performance characteristics, are less affected by environmental factors such as humidity, and often offer enhanced durability compared to traditional core materials. However, the use of synthetic materials is subject to regulations and must meet established standards.

Can the choice of core material impact the risk of injuries in baseball?

Yes, the choice of core material can impact the risk of injuries in baseball. Softer core materials, like rubber, can reduce the risk of injuries upon impact with a player’s body, while denser core materials, such as cork, may pose a higher risk. Proper regulation and testing ensure that the core material used strikes an appropriate balance between performance and safety.

How do different core materials impact ball behavior in specific weather conditions?

Various core materials can behave differently in different weather conditions. For example, cork cores may shrink or expand based on humidity levels, potentially impacting the ball’s flight. Conversely, rubber cores are more resistant to weather-related changes. Manufacturers consider these factors when designing baseballs to ensure they perform consistently across various weather conditions.

Do different core materials affect the cost of baseballs?

Yes, the choice of core material can have an impact on the cost of baseballs. Natural materials, such as cork, may be more expensive due to their limited availability and processing requirements, while synthetic alternatives might offer more cost-effective options. However, other factors such as manufacturing techniques and overall quality also influence the final cost of baseballs.

Final Thoughts on Inside Baseballs: Core Materials and Performance

Understanding the core materials and their significance in baseballs is vital for players, coaches, and enthusiasts alike. The choice of core material can greatly impact a baseball’s performance, including its flight, speed, and overall playability. It is essential for manufacturers to strike a balance between performance, safety, and adherence to regulations to ensure a fair and enjoyable game for all.

With ongoing advancements in materials science, we can expect further improvements in baseball core materials. Manufacturers are continually exploring new possibilities and experimenting with innovative materials to enhance the game. As the understanding of core materials’ impact on performance deepens, we can look forward to future baseballs that push the boundaries of what is possible on the field.