Vulcanization: Transforming Materials into Sports Balls

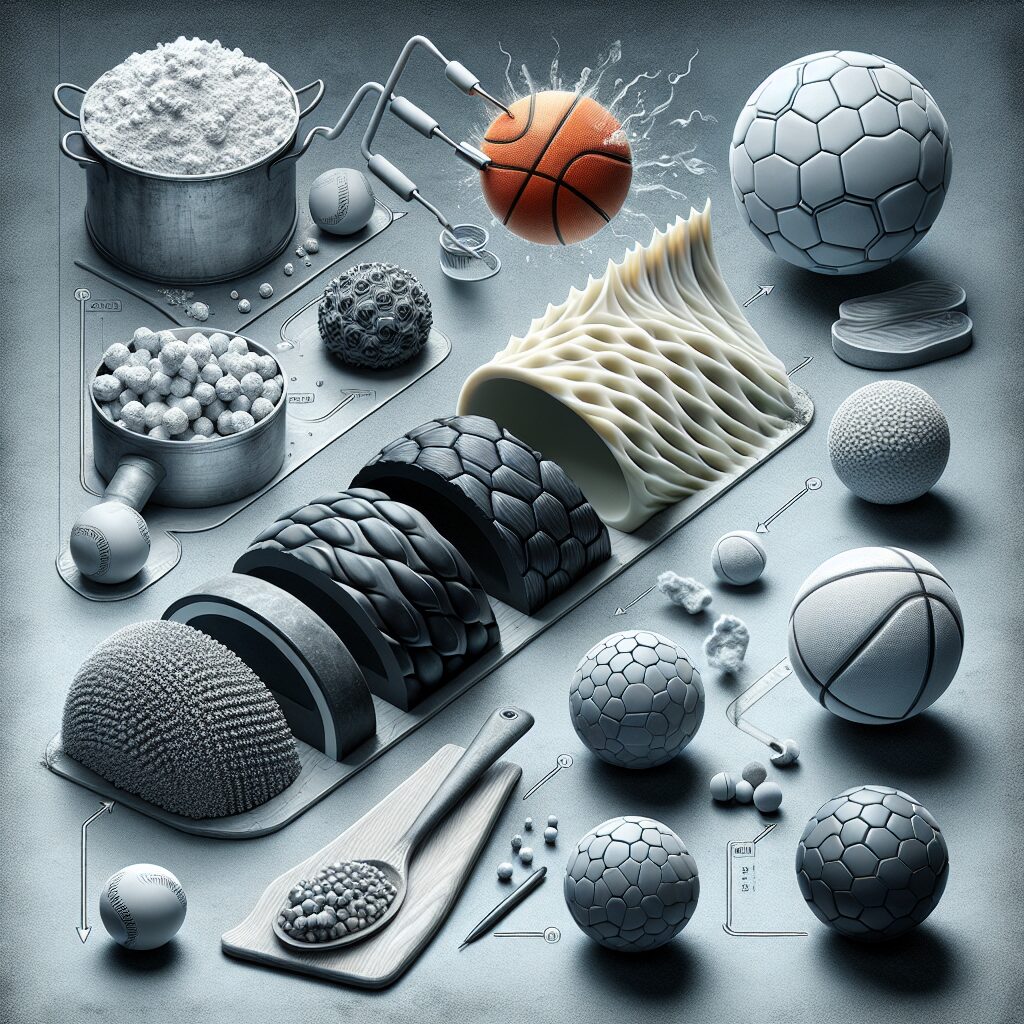

Vulcanization is a process that plays a crucial role in the manufacturing of sports balls. It involves the transformation of raw materials into durable, resilient, and high-quality materials that are essential for the performance of sports balls. This process, initially developed by Charles Goodyear in the mid-19th century, involves treating rubber or similar polymers with sulfur or other curatives to enhance their properties.

One unique fact about vulcanization is that it vastly improves the physical characteristics of the materials used in sports balls. By subjecting the raw materials to intense heat and pressure, the molecular structure of rubber is altered, resulting in a material that is more resistant to wear, abrasion, and deformation. This transformation leads to the creation of sports balls that can withstand the rigorous demands of various sports, ensuring consistent performance and durability.

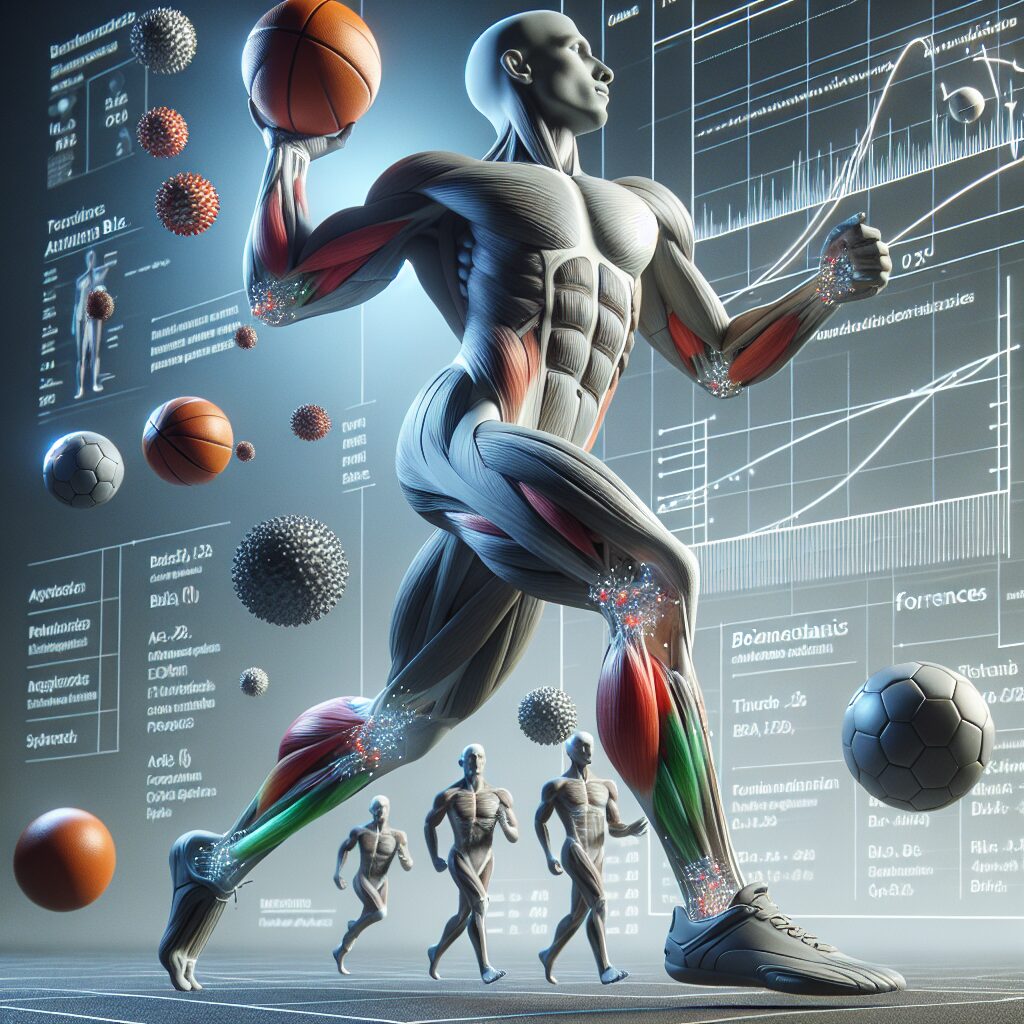

In the upcoming portion of this article, we will explore the key takeaways of vulcanization. We will dive deeper into the specific impacts this process has on the performance of sports balls, highlighting the enhanced bounce, grip, and overall longevity. Additionally, we will discuss the unique features that vulcanization brings to different types of sports balls, such as basketballs, soccer balls, and tennis balls, shedding light on how this process revolutionized the world of sports equipment. Stay tuned to uncover the fascinating world of vulcanization and its profound influence on the sporting realm.

Key Takeaways

1. Vulcanization is a crucial process used to transform raw rubber into more durable and resilient materials for various applications, including sports balls.

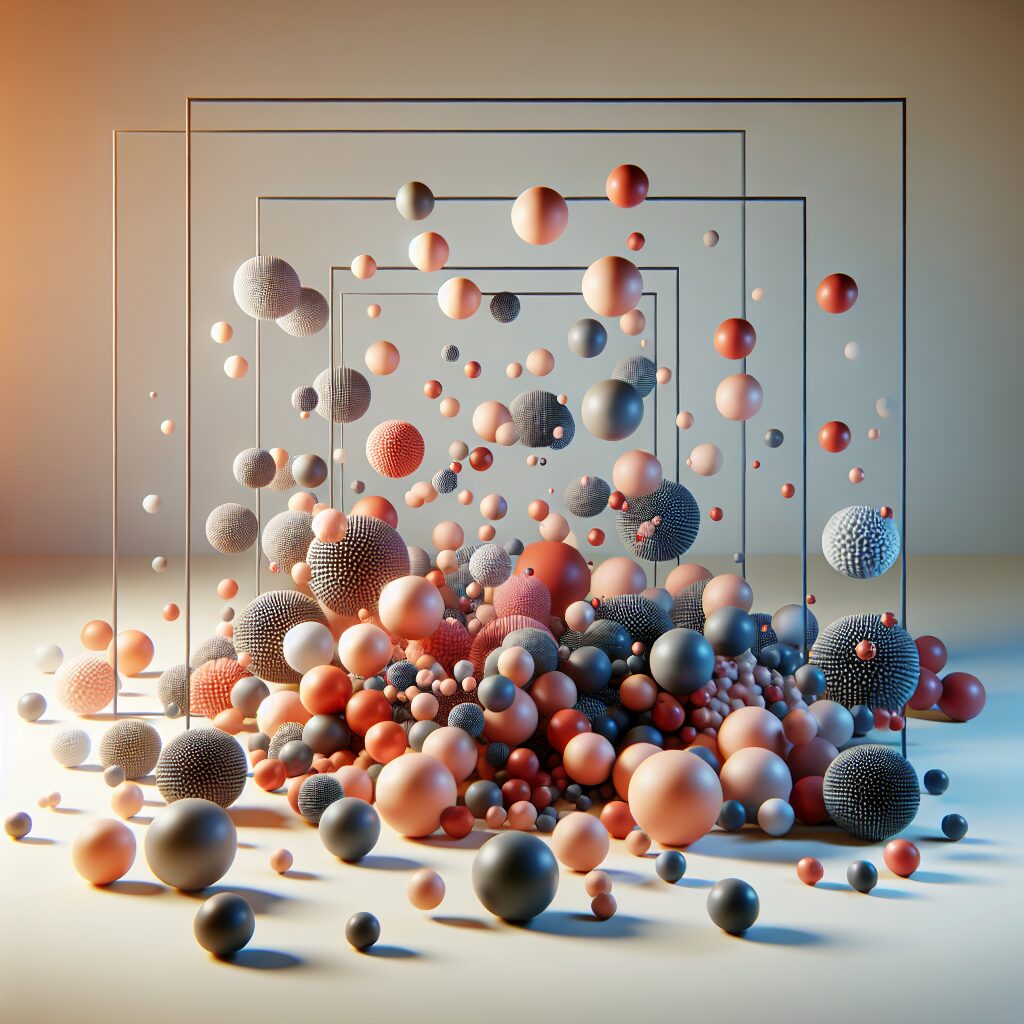

2. The vulcanization process involves heating the rubber compound with sulfur, which creates covalent cross-links between polymer chains, resulting in increased strength and elasticity.

3. By controlling factors such as temperature, time, and the composition of the rubber compound, manufacturers can tailor the properties of vulcanized materials to meet specific requirements for different sports balls.

4. Vulcanized materials offer enhanced performance characteristics for sports balls, including improved impact resistance, better rebound, increased durability, and resistance to wear and deformation.

5. The benefits of vulcanization have led to the widespread use of vulcanized rubber in sports balls like basketballs, soccer balls, and tennis balls, providing athletes with reliable and high-performing equipment.

How Does Vulcanization Transform Materials into Sports Balls?

The Process of Vulcanization

Vulcanization is a crucial process in the manufacturing of sports balls, as it transforms raw materials into durable and resilient products. This section delves into the step-by-step procedure of vulcanization.

Rubber Mixing

The first step in vulcanization is rubber mixing, where various ingredients such as raw rubber, fillers, and chemicals are combined to form a uniform compound. This mixture is then further processed to achieve the desired properties.

Heat and Pressure Application

After rubber mixing, the compound is shaped into the form of the sports ball through molding or extrusion. The semi-finished product is then subjected to a combination of heat and pressure, which triggers the vulcanization process.

Chemical Reaction

During vulcanization, a chemical reaction takes place between the rubber compound and a crosslinking agent, commonly sulfur. This reaction forms strong bonds between the polymer chains, resulting in a solid and sturdy material.

Curing Time and Temperature

Proper curing time and temperature are essential for obtaining optimal vulcanization. Different materials and ball types require specific parameters, and manufacturers carefully monitor these variables to ensure quality and consistency.

Benefits of Vulcanization in Sports Balls

Vulcanization offers several advantages when it comes to manufacturing sports balls. This section highlights the benefits that this transformative process brings to the overall quality and performance of sports balls.

Enhanced Durability

Through vulcanization, the materials used in sports balls become more durable and resistant to wear and tear. The process creates a robust matrix of crosslinked polymers, allowing the ball to withstand intense impacts and maintain its shape over time.

Improved Resilience

Vulcanization also imparts resilience to sports balls, making them resistant to deformation and providing a lively bounce. The crosslinked structure enhances the elasticity of the materials, resulting in a more dynamic and responsive ball during gameplay.

Consistent Performance

By transforming materials through vulcanization, sports ball manufacturers can ensure consistent performance across their product range. Vulcanized balls exhibit uniform properties and characteristics, allowing players to experience reliable performance every time they use the ball.

Weather Resistance

Vulcanization enhances the resistance of sports balls to various environmental conditions. These vulcanized products can withstand extreme temperatures, humidity, and exposure to UV radiation, making them suitable for outdoor use in all climates.

Numbered Guides: Tips for Vulcanization in Sports Ball Manufacturing

- Utilize precise rubber compound formulations tailored to the requirements of each specific sports ball.

- Ensure accurate measurement and incorporation of crosslinking agents, such as sulfur, during rubber mixing.

- Maintain consistent heat and pressure levels during the vulcanization process for reliable results.

- Optimize curing time and temperature parameters to achieve the desired material properties.

- Regularly test and inspect vulcanized sports balls to uphold quality standards and address any issues promptly.

Frequently Asked Questions

1. What is vulcanization?

Vulcanization is a chemical process used to transform raw materials into durable and resilient materials by cross-linking their molecules. It involves the addition of sulfur or other curatives to rubber or polymers, resulting in improved strength, elasticity, and resistance to wear and tear.

2. How does vulcanization impact the production of sports balls?

Vulcanization plays a crucial role in the production of sports balls. By subjecting the materials used for the balls to the vulcanization process, it enhances the characteristics required for optimal performance. The vulcanized materials become more durable, able to withstand high impacts, and maintain their shape and bounce over extended periods of use.

3. Are all sports balls produced through vulcanization?

No, not all sports balls are produced through vulcanization. While vulcanization is commonly used for producing rubber-based sports balls, such as basketballs and soccer balls, there are other manufacturing techniques for different types of balls. For instance, stitched leather balls like baseballs and tennis balls are not vulcanized.

4. Can vulcanization be applied to other materials besides rubber?

Yes, vulcanization can be applied to materials other than rubber. While rubber is the most common material subjected to vulcanization, the process can also be used with certain types of plastics and elastomers to enhance their qualities. However, the specific curatives and conditions may vary depending on the material being vulcanized.

5. Does vulcanization affect the cost of sports balls?

Vulcanization can slightly impact the cost of sports balls due to the additional processing steps and materials required. However, it is essential to consider the long-term benefits of vulcanized sports balls, such as extended durability and performance. The minimal increase in cost is often justified by the superior quality and longevity of the vulcanized product.

6. Is vulcanization harmful to the environment?

The vulcanization process itself does not pose significant harm to the environment. However, certain chemicals used in the process, such as sulfur, can have environmental implications if not handled and disposed of properly. Manufacturing facilities usually have measures in place to minimize and manage any potential environmental impact associated with vulcanization.

7. Can vulcanized sports balls be recycled?

Yes, vulcanized sports balls can be recycled, although the process is more challenging than recycling regular rubber or plastic materials. Due to the cross-linking of molecules during vulcanization, the materials become less malleable and more difficult to break down. However, there are innovative recycling methods being developed to tackle this challenge and promote sustainability in the sports ball industry.

8. Are vulcanized sports balls suitable for all playing surfaces?

Generally, vulcanized sports balls are suitable for a wide range of playing surfaces, including indoor courts and outdoor fields. Their enhanced durability allows them to withstand the various conditions encountered during gameplay. However, it’s essential to choose a ball specifically designed for the intended playing surface to optimize performance and longevity.

9. How long does vulcanization process typically take?

The duration of the vulcanization process can vary depending on factors such as the type of material, desired properties, and manufacturing scale. In most cases, vulcanization can take anywhere from a few minutes to several hours. The process involves carefully controlling temperature, pressure, and curing time to achieve the desired material transformation.

10. Can vulcanization be done manually or is it automated?

Vulcanization can be performed using both manual and automated methods. In smaller-scale operations or specialized applications, manual vulcanization may be carried out by skilled technicians who carefully control the process variables. On the other hand, larger manufacturing facilities often employ automated vulcanization processes for efficiency and consistency.

Final Thoughts on Vulcanization: Transforming Materials into Sports Balls

Vulcanization has revolutionized the sports ball industry by transforming ordinary materials into extraordinary products. Through this chemical process, the durability, performance, and lifespan of sports balls have significantly improved. Vulcanization allows athletes to play with confidence, knowing that their equipment can withstand rigorous use and maintain its integrity throughout intense gameplay.

As technology continues to advance, there is undoubtedly room for further innovation in the field of vulcanization. Finding ways to make the process more sustainable, cost-effective, and adaptable to different materials will contribute to the evolution of sports balls. Whether it’s developing eco-friendly curatives or exploring alternative materials, the future of vulcanization holds promises of creating even better sports balls for athletes worldwide.