Latex bladders, also known as the heart of sports ball manufacturing, play a crucial role in the performance and durability of various sports balls. These bladders are made of latex, a natural material derived from the sap of rubber trees. One unique fact about latex bladders is that their elasticity and resilience allow them to retain their shape even after repeated impacts and intense pressure, making them ideal for sports ball production.

The use of latex bladders in sports ball manufacturing brings several specific impacts and unique features to the table. Firstly, the elasticity of latex bladders ensures that sports balls have a consistent bounce, enabling players to predict the trajectory of the ball accurately. Whether it’s a basketball soaring through the net or a soccer ball swerving past defenders, the consistent bounce provided by latex bladders adds an element of precision to the game. Additionally, the resilience of latex bladders enhances the durability of sports balls, making them better equipped to withstand the rigors of intense gameplay.

Moving forward, this article will delve into the key takeaways related to latex bladders in sports ball manufacturing. We will explore their impact on performance, the manufacturing process, and how they contribute to the overall user experience. By gaining insights into the science behind these essential components, readers can deepen their understanding of the intricacies that lie beneath the surface of their favorite sports balls. So, let’s embark on this journey to discover the fascinating world of latex bladders and their significant role in shaping the games we love.

Key Takeaways

1. Latex bladders play a crucial role in the manufacturing of sports balls, providing the essential internal structure that maintains shape and ensures optimal performance.

2. Latex bladders are typically made from natural rubber latex obtained from rubber trees, and their composition significantly affects the ball’s behavior, such as its bounce and in-flight characteristics.

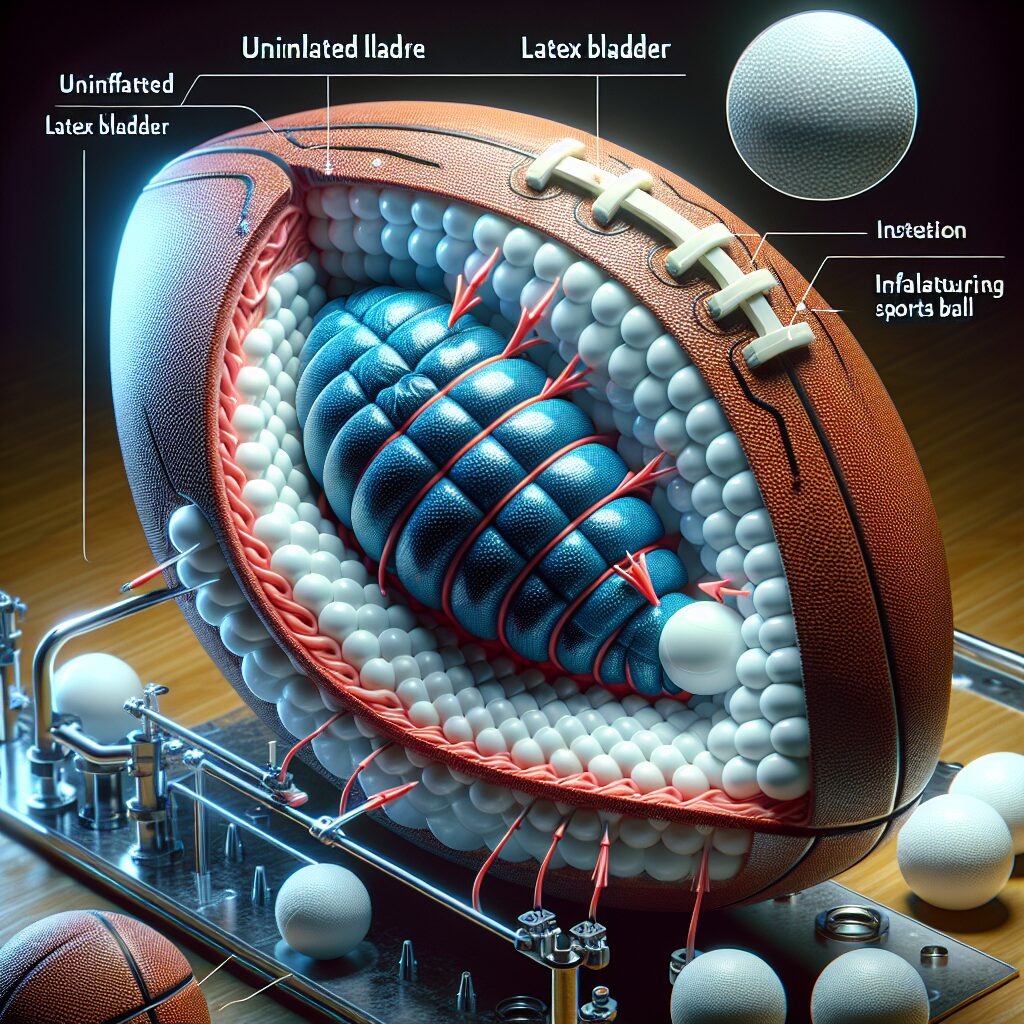

3. The manufacturing process of latex bladders involves the careful dipping of molds into latex tanks, followed by air drying and vulcanization to create a strong and elastic bladder.

4. Quality control is essential in ensuring that latex bladders meet the necessary standards, requiring thorough inspection for defects, such as air leaks or irregular shapes, to prevent manufacturing errors and maintain the desired performance of the sports balls.

5. Latex bladders are an integral part of various sports balls, including soccer, basketball, and volleyball, with manufacturers continually researching and innovating to improve their durability, longevity, and performance on the field.

What makes latex bladders the essential component of sports ball manufacturing?

1. Understanding the Importance of Latex Bladders

Latex bladders serve as the vital element in the production of sports balls, acting as the heart or core of the manufacturing process. These bladders, made from natural latex material, possess unique properties that significantly impact the performance, durability, and overall quality of sports balls.

2. The Manufacturing Process

When it comes to the production of sports balls, latex bladders are carefully crafted through a meticulous manufacturing process. The process involves preparing the latex material, creating the bladder shape, heating and curing, and finally inspecting and testing for quality assurance. Each step is crucial in ensuring the bladders meet the required standards for optimal ball performance.

3. Advantages of Latex Bladders

Latex bladders offer numerous advantages compared to alternative materials. Firstly, they provide superior elasticity, allowing the ball to better retain its shape and bounce consistently. Additionally, latex bladders offer excellent air retention, ensuring minimal deflation and maintaining optimal pressure during game play. The natural latex material also contributes to enhanced ball control and responsiveness, making it a preferred choice for professional athletes.

4. Factors Affecting Bladder Performance

The performance of a latex bladder can be influenced by various factors. The quality and purity of the latex material used, the curing process, and the design and construction of the bladder all play crucial roles in determining its durability, bounce, and overall performance. Sports ball manufacturers constantly strive to optimize these factors to produce bladders that exceed expectations.

5. Maintaining and Caring for Latex Bladders

Proper maintenance and care are essential to prolong the lifespan and performance of latex bladders. Regular inflation checks, storing the balls in appropriate conditions, and avoiding exposure to extreme temperatures or excessive moisture are all vital to ensure the bladders retain their optimal performance throughout their usage.

6. Innovation and Future Developments

The world of sports ball manufacturing is a continuous journey of innovation and improvement. Researchers and manufacturers are consistently exploring new materials and technologies to enhance the performance of latex bladders. These advancements aim to further improve ball consistency, durability, and overall playing experience for athletes worldwide.

Top Tips for Maximizing Latex Bladder Performance:

- Ensure proper inflation and maintain optimal pressure levels.

- Store the balls in a cool and dry environment to prevent degradation.

- Avoid exposing the balls to extreme temperatures or direct sunlight.

- Regularly inspect the bladders for any signs of wear or damage.

- Utilize appropriate cleaning methods and avoid abrasive materials.

- Consider purchasing balls from reputable manufacturers known for high-quality bladders.

- Follow the manufacturer’s guidelines and recommendations for optimal usage and care.

Frequently Asked Questions

What is a latex bladder?

A latex bladder is a component used in the manufacturing of sports balls such as soccer balls, basketballs, and volleyballs. It serves as the innermost layer of the ball, providing it with its shape and durability.

Why is a latex bladder important in sports ball manufacturing?

A latex bladder is important in sports ball manufacturing as it determines the ball’s responsiveness, bounce, and overall performance. Its flexibility allows the ball to maintain its shape during play, while providing the necessary rebound for optimal gameplay.

How are latex bladders made?

Latex bladders are made by extracting latex sap from rubber trees, then mixing it with various chemicals to create a liquid rubber compound. This compound is poured into molds and undergoes a vulcanization process, where it is heated and cured to form solid latex bladders.

What are the advantages of using latex bladders in sports balls?

Latex bladders offer several advantages in sports ball manufacturing. They provide excellent air retention, ensuring that the ball maintains its desired pressure for extended periods of time. Latex bladders also offer superior elasticity, resulting in a more responsive and lively ball.

Are latex bladders durable?

Yes, latex bladders are known for their durability. They can withstand rigorous use and maintain their shape and performance for a long time. However, their lifespan can be influenced by factors such as the quality of the latex used, the manufacturing process, and the care taken by the user.

Can latex allergies be a concern with latex bladders?

While latex allergies can be a concern for some individuals, the use of latex bladders in sports balls is generally safe. The latex is vulcanized during the manufacturing process, which reduces the risk of allergic reactions. However, individuals with known latex allergies should exercise caution while handling latex-bladder sports balls.

How should I care for a sports ball with a latex bladder?

To care for a sports ball with a latex bladder, it is important to store it in a cool and dry place when not in use, away from direct sunlight and extreme temperatures. Regularly check the ball’s pressure and inflate as needed. Avoid exposing the ball to sharp objects or excessive impact, as it can damage the latex bladder.

Can latex bladders be replaced?

Yes, in most cases, latex bladders can be replaced. Many sports ball manufacturers offer replacement bladders for their products. It is important to consult the manufacturer’s guidelines or seek professional help for proper replacement.

Do all sports balls use latex bladders?

No, not all sports balls use latex bladders. Some balls, particularly those used in lower-level or recreational play, may utilize alternative materials such as rubber or synthetic bladders. The choice of bladder material depends on factors such as performance requirements, cost, and target market.

Where can I learn more about sports ball manufacturing?

For more information about sports ball manufacturing, you can refer to industry publications, online resources, or consult with sports ball manufacturers directly. They can provide detailed insights into the manufacturing process, materials used, and the latest advancements in the field.

Final Thoughts

Latex bladders play a crucial role in the manufacturing of sports balls, serving as their heart. The flexibility, durability, and performance of these bladders contribute significantly to the overall quality of the ball. Whether you’re a professional athlete or a recreational player, understanding the importance of latex bladders can enhance your appreciation for the game.

Next time you kick a soccer ball or shoot a basketball, take a moment to recognize the craftsmanship that goes into creating these sporting essentials. The engineering behind latex bladders ensures that you experience the perfect bounce, responsiveness, and playability that make you fall in love with your favorite sports.