Heat Curing: The Final Step in Ball Manufacturing

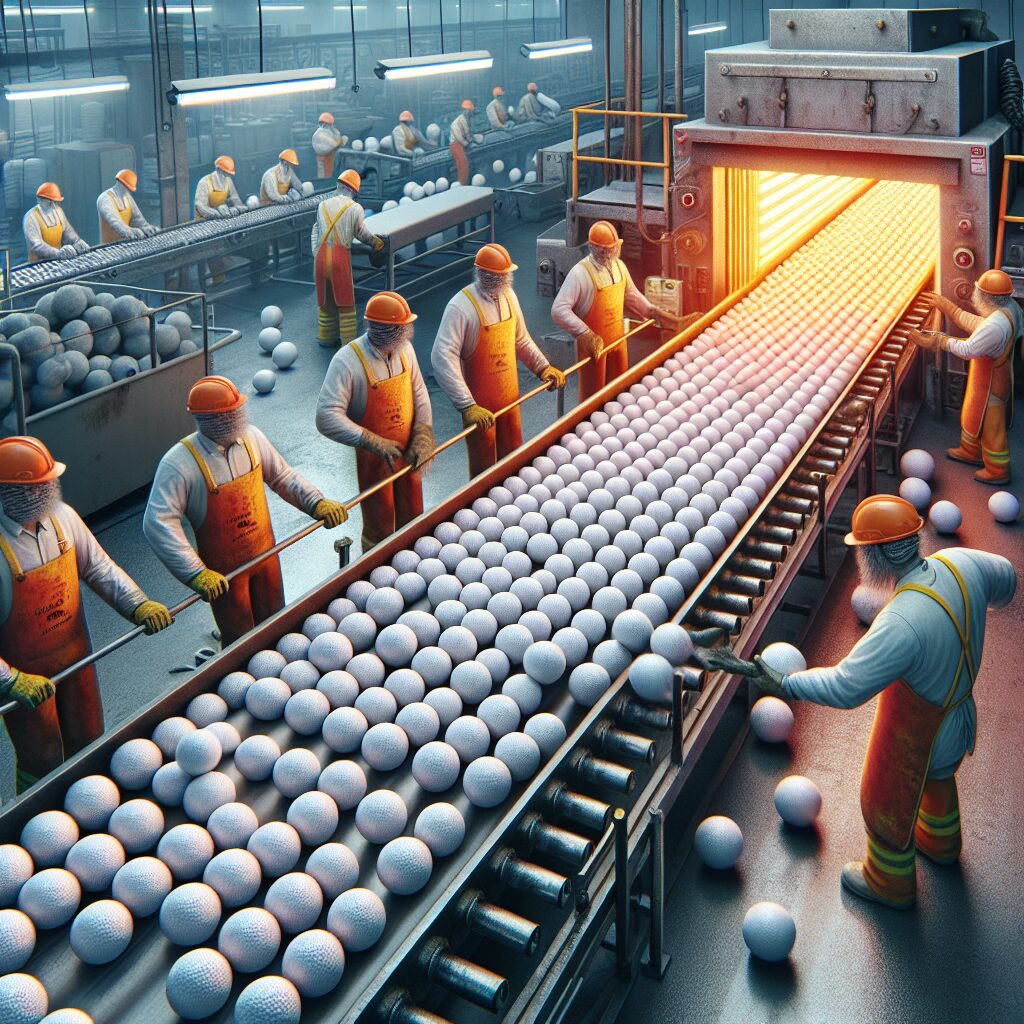

In the intricate world of ball manufacturing, one crucial step stands out among the rest – heat curing. This process involves subjecting the newly formed balls to controlled temperatures, resulting in the transformation of their internal structure and properties. Heat curing plays a fundamental role in ensuring the quality and durability of the balls, making it an essential step in the manufacturing process.

Unlike other manufacturing steps, heat curing offers distinct impacts and unique features. The controlled heating process allows for the consolidation and strengthening of the ball’s structure, enhancing its resistance to wear and tear. This results in longer-lasting balls that can withstand the rigors of intense usage, whether in sports competitions, industrial applications, or precision instruments. Moreover, heat curing imparts desirable properties to the balls, such as increased hardness or improved flexibility, depending on the specific requirements of their end-use.

Looking ahead, it is important to delve into key takeaways regarding heat curing. This article will explore the various factors influencing the heat curing process, including the temperatures and duration required for optimal results. Additionally, we will discuss the effect of different materials used in ball manufacturing on the heat curing process and their subsequent impact on ball performance. By understanding these key takeaways, manufacturers and consumers alike can gain valuable insights into the significance of heat curing in ensuring the integrity and longevity of balls in various industries. Stay tuned to discover the science behind this final step in ball manufacturing!

Key Takeaways

1. Heat curing is a critical final step in ball manufacturing, ensuring the ball’s durability and performance by stabilizing its core.

2. The heat curing process involves subjecting the ball to high temperatures in an oven, allowing the reactive chemicals in the core to generate a solid and uniform structure.

3. The curing process takes various factors into account, such as the ambient temperature, duration, and specific curing profile, to achieve the desired ball properties.

4. It is crucial to maintain precise control over the curing process parameters to avoid deformations or inconsistencies in the ball’s structure, which could negatively impact its performance and longevity.

5. Quality control techniques, such as non-destructive testing, are employed to detect any defects or inhomogeneities in the cured ball, ensuring only high-quality products reach the market.

What is Heat Curing in Ball Manufacturing and Why is it Important?

Heat curing is the crucial final step in the manufacturing process of balls used in various industries, including sports, automotive, and aerospace. This process involves subjecting the ball to controlled heat for a specific duration to achieve desirable physical and chemical properties. Heat curing plays a pivotal role in enhancing the durability, performance, and overall quality of the ball. In this article, we will explore the various aspects surrounding heat curing in ball manufacturing.

The Science Behind Heat Curing

Heat curing involves carefully manipulating the temperature and time to trigger chemical reactions within the materials comprising the ball. The process primarily aims to enhance the stability, hardness, and elasticity of the ball. During heat curing, the molecular structure of the materials undergoes changes, resulting in improved strength and resistance to wear and tear.

The Steps Involved in Heat Curing

1. Preheating: Before the actual curing process, the ball goes through preheating. This step raises the temperature gradually to ensure uniform heating and minimize thermal shock.

2. Curing Temperature: The choice of curing temperature depends on the specific material used in the ball. It is crucial to maintain accurate temperature control throughout the process to avoid overheating or underheating, both of which can compromise the quality of the ball.

3. Curing Time: The duration for heat curing can vary based on factors like the material, ball size, and desired properties. Longer curing time generally leads to better curing and improved characteristics of the ball.

4. Cooling: After the curing process, the ball is cooled gradually to room temperature. This step prevents abrupt cooling, which can cause thermal stress, dimensional changes, or cracking.

The Benefits of Heat Curing

1. Enhanced Durability: Heat curing allows the ball to withstand extreme conditions, resist deformation, and prolong its longevity.

2. Improved Performance: The controlled heating process enhances the ball’s uniformity, accuracy, and consistency, resulting in superior performance on the field or in industrial applications.

3. Increased Strength: Heat curing increases the ball’s structural strength, making it more resistant to impact and stress, thus reducing the risk of breakage.

Guidelines for Effective Heat Curing

- What is the optimal curing temperature and duration for specific ball materials?

- How should the cooling process be carried out to avoid thermal stress?

- Are there any additional post-curing treatments or inspections recommended for quality assurance?

- What are the safety measures to be followed during heat curing to ensure a safe working environment?

Frequently Asked Questions

1. What is heat curing?

Heat curing is the final step in ball manufacturing, where the newly formed ball undergoes a controlled heating process to enhance its physical properties, such as hardness and durability.

2. How does heat curing affect the quality of the ball?

Heat curing significantly improves the quality of the ball by ensuring uniform and consistent material properties throughout its structure. It helps eliminate any residual stress or weaknesses present in the ball, enhancing its performance and longevity.

3. Why is heat curing considered crucial in ball manufacturing?

Heat curing is crucial in ball manufacturing because it provides the necessary structural integrity required for the ball to withstand the rigorous conditions of its intended usage. It improves its resistance to wear, impacts, and deformations, making it suitable for various applications.

4. What temperatures are typically used for heat curing?

The temperatures used for heat curing in ball manufacturing can vary depending on the specific material and desired properties. Generally, temperatures ranging from 150 to 200 degrees Celsius are common, but it may vary for different types of balls.

5. How long does the heat curing process take?

The duration of the heat curing process for ball manufacturing depends on factors such as the ball size, material composition, and desired properties. Typically, it can range from a few minutes to several hours.

6. Can heat curing damage the ball?

No, when performed correctly, heat curing does not damage the ball. It is a controlled process that aims to enhance the ball’s properties without causing any harm. However, improper heat curing procedures or excessive temperatures can potentially harm the ball.

7. Is heat curing a standard process for all types of balls?

Heat curing is a standard process for many types of balls, especially those made from materials like rubber, plastic, or composite materials. However, it may not be applicable to all types of balls, such as some specialized balls made from unique materials.

8. Can heat curing be done at home?

No, heat curing is a specialized process that requires controlled industrial equipment and precise temperature control. It is best left to professional ball manufacturers to ensure proper and consistent curing results.

9. What are the advantages of heat curing in ball manufacturing?

The advantages of heat curing in ball manufacturing include improved hardness, enhanced durability, better consistency in material properties, increased resistance to wear and impact, and overall superior performance of the ball.

10. Can heat curing be applied to used or damaged balls?

No, heat curing cannot be effectively applied to used or damaged balls. It is primarily a process for freshly manufactured balls to enhance their properties. If a ball is damaged, it is recommended to replace it rather than attempting heat curing.

Final Thoughts

Heat curing plays a vital role in the final step of ball manufacturing, ensuring the production of high-quality and durable balls. It is a process that greatly benefits industries and sports enthusiasts alike by providing reliable and effective equipment. Proper heat curing techniques and control are necessary to achieve desired results and maximize the performance and lifespan of the balls.

In summary, understanding the importance of heat curing and its effects on ball properties is crucial for both manufacturers and consumers. The combination of precise temperature control, optimized curing duration, and suitable materials leads to superior balls that meet industry standards and provide satisfactory performance. Whether it’s sports, industrial applications, or recreational activities, heat-cured balls are essential for optimal performance and longevity.