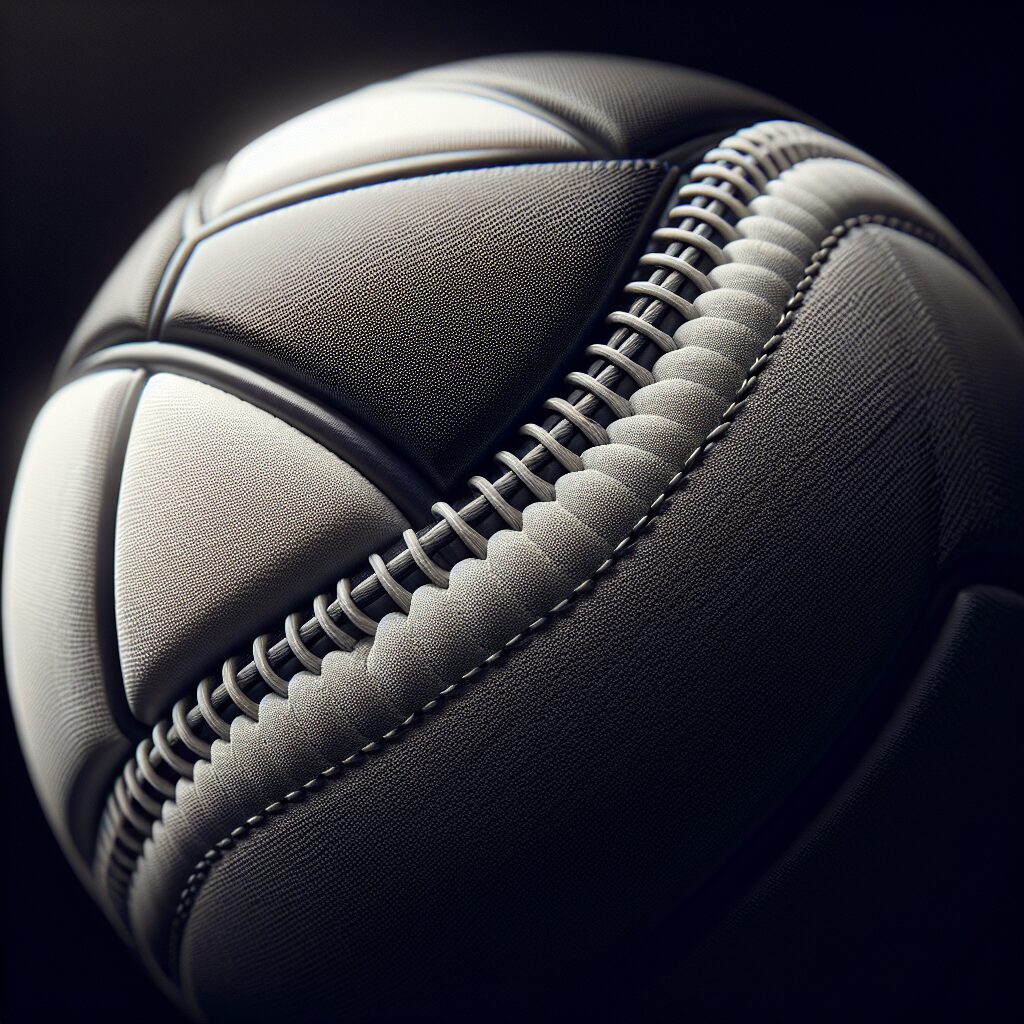

Seam stitching is a crucial element that contributes to the durability and performance of sports balls. Whether it’s a basketball, soccer ball, or volleyball, the quality of seam stitching can determine how long the ball lasts and how well it performs on the field. The stitching is where the panels of the ball are sewn together, creating a sturdy and reliable structure. Did you know that the placement and type of stitching can significantly impact the ball’s flight and bounce? It’s an essential aspect that manufacturers and athletes alike pay close attention to.

When it comes to seam stitching, different sports balls have specific requirements. For example, in soccer, the stitching must be strong enough to endure intense kicks and frequent impacts with the ground. In basketball, the stitches need to be smooth and precise to enable consistent shooting and dribbling. Additionally, the seams must hold up against the abrasive nature of outdoor play. Volleyballs, on the other hand, require tight, controlled stitching to maintain their shape and allow for optimal control during spikes and serves.

Now that we understand the importance of seam stitching in sports balls, let’s dive into the key takeaways. In the upcoming sections, we will explore the various types of stitching used in different sports balls, the impact of innovative stitching techniques on performance, and the role of quality materials in enhancing durability. So, keep reading to uncover the secrets behind the seam stitching that makes sports balls truly exceptional.

Key Takeaways

1. Seam stitching plays a crucial role in the durability and performance of sports balls, as it helps maintain the shape and integrity of the ball during intense play. The skillful art of seam stitching requires precision and expertise to ensure a long-lasting product.

2. The choice of thread used in seam stitching greatly impacts the durability and strength of sports balls. High-quality, durable threads such as polyester or nylon are commonly used to withstand the wear and tear of repetitive impacts and provide stability to the seams.

3. Proper tension and stitching techniques are essential for ensuring the longevity of sports balls. Incorrect tension can result in weak seams and compromised performance, while well-executed stitching techniques can enhance the ball’s resistance and response during gameplay.

4. The design and positioning of seams are key factors in determining the ball’s flight characteristics, grip, and overall performance. Different sports require specific seam patterns and configurations to optimize the ball’s behavior, whether it’s for a predictable trajectory or enhanced ball control.

5. The quality of the seam stitching has a direct impact on the safety of players. Well-stitched seams prevent the ball from bursting or unraveling, reducing the risk of injury during play. Striving for excellence in every stitch is vital to maintaining the trust and safety of athletes across various sports.

**SEO Optimized Article Title Question:**

Is Seam Stitching the Key to Achieving a Durable Sports Ball?

**Section 1: Introduction to Seam Stitching**

Seam stitching plays a crucial role in the durability and performance of a sports ball. Whether it’s a football, basketball, soccer ball, or any other type of ball, the quality of the stitching can significantly impact its longevity and playing characteristics.

**Section 2: Understanding Seam Stitching Techniques**

2.1 Hand Stitching

Seam stitching can be done by hand or by using specialized machinery. Hand stitching involves skilled artisans carefully sewing together the panels of the sports ball using a needle and thread. This method allows for precise control and attention to detail, resulting in a strong and durable seam.

2.2 Machine Stitching

Machine stitching, on the other hand, utilizes advanced equipment that automates the stitching process. While it may lack the fine craftsmanship of hand stitching, machine stitching ensures uniformity and speed, making it suitable for mass production.

2.3 Double-Stitching

In some cases, sports balls are reinforced with double-stitching. This technique involves adding a secondary line of stitching parallel to the primary seam, enhancing the ball’s strength and resistance to wear and tear.

**Section 3: Importance of Proper Seam Stitching**

3.1 Enhanced Durability

Effective seam stitching ensures that the panels of a sports ball remain securely joined, preventing the ball from coming apart during intense gameplay or rough handling. This durability is especially important for high-contact sports like soccer, rugby, or American football.

3.2 Shape Retention

The stitching of a sports ball helps maintain its desired shape and roundness. If the seams are weak or poorly stitched, the ball may deform or lose its form over time, affecting its aerodynamics and overall performance.

3.3 Seam Strength

A well-stitched seam provides excellent strength, allowing the ball to withstand the forceful impacts and rigorous use it may encounter during games or practices. A weak or compromised seam could lead to seam failure, resulting in the ball losing air or splitting apart.

**Section 4: Ensuring Quality Seam Stitching**

4.1 Material Selection

Using high-quality threads and materials is crucial for achieving durable seam stitching. Strong synthetic threads, such as nylon or polyester, are commonly preferred due to their resistance to stretching, abrasion, and moisture.

4.2 Stitch Pattern

The choice of stitch pattern can also influence the durability of a sports ball. Common stitch patterns include lock stitch, zig-zag stitch, or overlock stitch. Each pattern offers different levels of strength and flexibility, depending on the specific requirements of the ball.

4.3 Quality Control

Stringent quality control measures are essential during the stitching process. Regular inspections and testing should be carried out to identify any potential flaws or weaknesses in the seams, ensuring only the highest standard balls reach the market.

**Section 5: Expert Tips for Maintaining Seam Stitching**

5.1 Regular Cleaning and Maintenance

Frequent cleaning using appropriate methods and avoiding harsh chemicals can help preserve the integrity of the stitching. Proper maintenance, including correctly inflating and storing the ball, minimizes stress on the seams, prolonging their lifespan.

5.2 Avoid Excessive Exposure to Extreme Conditions

Extreme temperature changes, direct sunlight, or excessive moisture can degrade the stitching over time. Protecting the sports ball from such conditions can prevent seam deterioration.

5.3 Handle the Ball with Care

Rough handling, excessive kicking, or throwing the ball against hard surfaces can put unnecessary strain on the seams. Teaching players proper technique and emphasizing the importance of respecting the equipment can extend the life of the stitching.

5.4 Promptly Repair Any Damaged Seams

If any stitching issues arise, such as loose threads or seam breakage, immediate repair is crucial. Ignoring or delaying repairs can lead to further damage and compromise the ball’s overall durability.

In conclusion, seam stitching is undeniably the key to achieving a durable sports ball. Proper techniques, materials, and maintenance are integral to ensuring the longevity, shape retention, and overall performance of sports balls used in various sports.

Frequently Asked Questions

1. What is seam stitching and why is it important?

Seam stitching is the process of joining the panels of a sports ball together using strong stitches. It is important because it ensures the durability of the ball by preventing the panels from coming apart during gameplay.

2. How does the quality of seam stitching affect the performance of a sports ball?

The quality of seam stitching directly influences the performance of a sports ball. Poor stitching can lead to an uneven surface, affecting the ball’s flight and bounce. On the other hand, high-quality stitching enhances the ball’s stability, consistency, and overall performance.

3. Are there different types of seam stitching techniques used for sports balls?

Yes, there are various seam stitching techniques employed for different sports balls. Common methods include hand stitching, machine stitching, and hybrid stitching techniques that combine both manual and automated processes. The choice of technique depends on factors such as the type of material, ball design, and desired level of durability.

4. Can a sports ball with poor seam stitching be repaired?

In some cases, it may be possible to repair a sports ball with poor seam stitching. However, it is often more cost-effective to replace the ball with a new one that has reliable stitching. Repairing may compromise the ball’s integrity and performance, so it is advisable to consult a professional before attempting any repairs.

5. What materials are commonly used for seam stitching sports balls?

Sports balls are typically stitched using strong synthetic threads, such as polyester or nylon. These materials offer excellent resistance to wear, tear, and exposure to various weather conditions, ensuring the longevity of the seam stitching.

6. How can I identify if a sports ball has quality seam stitching?

To determine the quality of seam stitching, examine the ball carefully. Look for even and tight stitches that securely hold the panels together without any loose ends. Additionally, check for reinforced stitching at stress points such as the seams and joints.

7. Are there any specific care instructions for sports balls with seam stitching?

Yes, it is essential to properly care for sports balls with seam stitching to maintain their durability. Avoid exposing them to extreme heat or cold, high humidity, or abrasive surfaces. Regularly clean and dry the ball after use, and store it in a cool and dry place to prevent damage to the stitching.

8. Can seam stitching affect the grip of a sports ball?

While seam stitching itself does not directly impact the grip of a sports ball, it plays a crucial role in maintaining the ball’s shape and integrity. A ball with properly stitched seams will provide a more consistent and reliable grip during gameplay.

9. How long can a sports ball with quality seam stitching last?

The lifespan of a sports ball with quality seam stitching depends on various factors, including the frequency of use, playing conditions, and maintenance. However, with proper care, such a ball can last for several seasons, offering consistent performance and durability.

10. Are there any specific regulations regarding seam stitching in different sports?

Yes, different sports governing bodies have specific regulations regarding the seam stitching of sports balls. These regulations ensure fair gameplay and uniformity in performance. It is important to check the guidelines set by the particular sport’s governing body to ensure compliance with seam stitching requirements.

Final Thoughts

Seam stitching is indeed the key to a durable sports ball. Whether it’s a soccer ball, basketball, or any other sports ball, proper stitching ensures longevity, reliable performance, and player satisfaction. By using strong and precise seam stitching techniques, manufacturers can create durable sports balls capable of withstanding intense gameplay.

Investing in sports balls with quality seam stitching not only enhances the overall experience for athletes but also saves money in the long run. With proper care, these sports balls can accompany players through countless matches, withstanding the demands of the game. So, make sure to choose a sports ball that boasts reliable seam stitching to enjoy durable performance and maximize your sporting prowess.