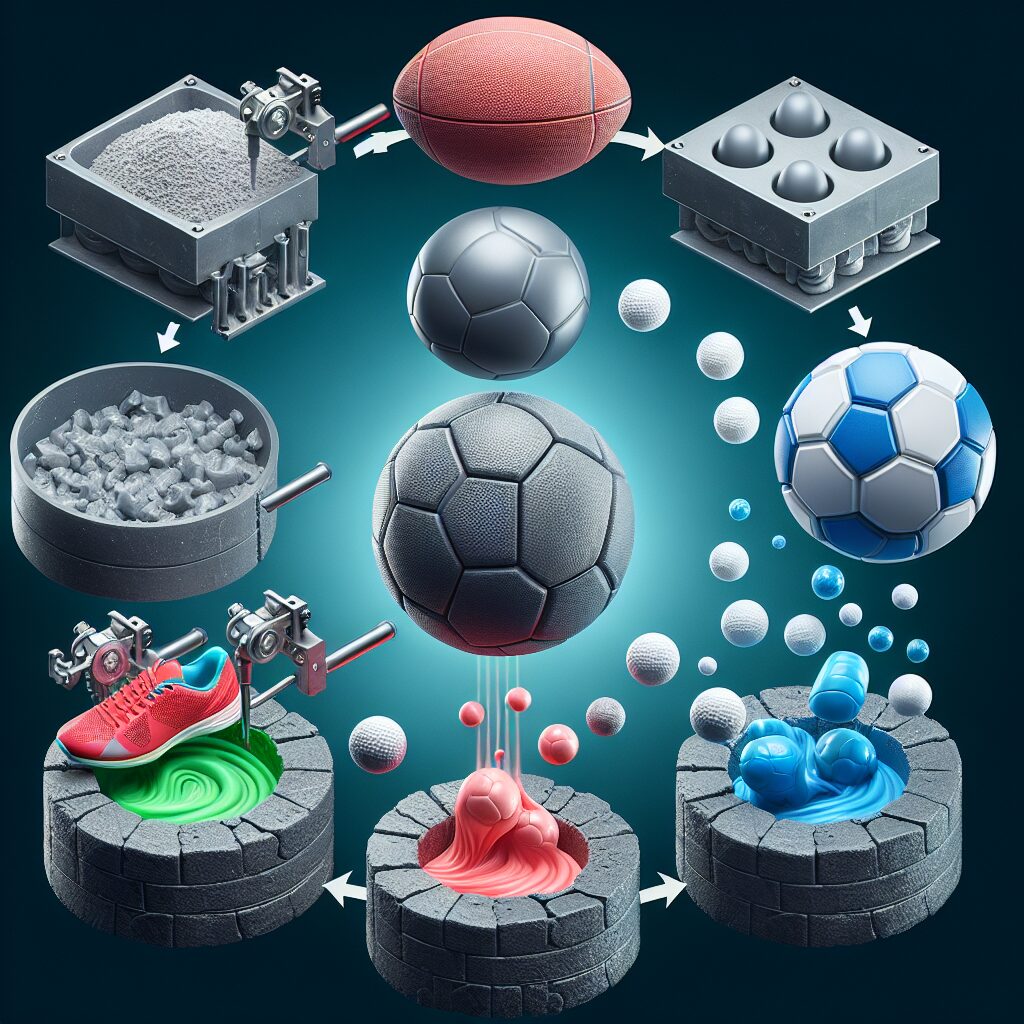

Rubber molding is a process of shaping materials into various forms, in this case, sports balls. This method involves the use of rubber or elastomers that are heated and then pressed or injected into specific molds to create the desired shape. This technique is widely used in the manufacturing of sports balls such as basketballs, footballs, and soccer balls.

One unique fact about the rubber molding process is that it allows for the production of sports balls with consistent shape and quality. This is achieved by using precise molds that are designed to meet the required specifications of each ball. Additionally, the flexibility of rubber ensures that the balls are resilient, providing optimal performance during sports activities. Furthermore, rubber molding is known for its ability to produce high-quality, durable balls that can endure rigorous use.

In the next part of this article, we will discuss the key takeaways of rubber molding in sports ball manufacturing. We will delve into the importance of material selection, the impact of the molding process on ball performance, and the role of technology in improving the overall quality of sports balls. Stay tuned to discover how rubber molding has revolutionized the production of sports equipment, ensuring that athletes across various disciplines can enjoy the best playing experience possible.

Key Takeaways

1. Rubber molding is a key process used to shape materials into sports balls, enabling manufacturers to create durable and high-performance products.

2. Different types of molds, such as injection molds and compression molds, are used in the rubber molding process to achieve precise and complex ball designs.

3. The type of rubber material used significantly impacts the performance and characteristics of the sports ball. Manufacturers carefully select the rubber compound based on factors such as elasticity, durability, and grip.

4. Quality control measures, including rigorous testing procedures, are essential to ensure that the molded sports balls meet strict standards and regulations. These tests evaluate factors like rebound, roundness, hardness, and weight.

5. Advances in rubber molding technology, such as computer-aided design (CAD) and automation, have greatly improved efficiency and precision in the manufacturing process, resulting in better quality sports balls.

How can Rubber Molding Shape Materials into Sports Balls?

Understanding Rubber Molding Process

Rubber molding is a widely used manufacturing process that involves shaping various materials into sports balls. This process allows for the production of high-quality and durable balls that are essential for different sports activities. In rubber molding, materials like natural or synthetic rubber are heated and then molded into specific shapes and sizes. The unique properties of rubber enable it to provide the necessary bounce, grip, and durability required for sports balls.

The Importance of Material Selection

When it comes to rubber molding for sports balls, material selection plays a crucial role. The choice of rubber material depends on the particular sport and the desired characteristics of the ball. Natural rubber, for example, offers excellent elasticity and grip, making it suitable for sports like basketball and volleyball. On the other hand, synthetic rubbers such as neoprene or butyl are preferred for their enhanced durability and resistance against harsh weather conditions, making them ideal for outdoor sports like soccer or rugby.

The Mold Design Process

Creating an effective mold design is a critical step in rubber molding for sports balls. The mold design determines the final shape and features of the balls, ensuring their performance and usability. Mold designers consider factors such as ball size, weight, surface texture, and grip to meet the requirements of various sports. Utilizing computer-aided design (CAD) software, designers create precise 3D models that guide the manufacturing process.

The Rubber Molding Techniques

Rubber molding for sports balls involves different techniques, each with its advantages and disadvantages. Compression molding is a commonly used method where rubber material is placed into a heated mold and compressed to shape it into a ball. Injection molding, on the other hand, injects rubber material into a closed mold under high pressure. This technique provides more control over the final product’s shape and consistency. Another technique called transfer molding combines elements of both compression and injection molding to achieve optimal results.

Quality Control and Testing

To ensure the production of high-quality sports balls, rigorous quality control and testing procedures are essential. Each ball undergoes thorough inspection to check for any defects, such as improper shape, air bubbles, or inconsistent texture. Additionally, various performance tests, including bounce, weight, and durability, are conducted to ensure the ball meets the required standards for specific sports. Quality control measures during rubber molding guarantee that customers receive reliable and safe sports balls.

Benefits of Rubber Molding for Sports Balls

Rubber molding offers several advantages for the production of sports balls. Firstly, it allows for flexibility in designing balls with customized shapes, sizes, and surface textures, catering to the unique requirements of different sports. Moreover, the durability and resilience of rubber enable the balls to withstand intense impacts and extensive use, resulting in longer lifespan and cost-effectiveness. Lastly, rubber molding ensures consistent quality and performance, making it a preferred method for manufacturing high-quality sports balls.

How to Choose the Right Rubber Molding Manufacturer?

1. Consider their experience in rubber molding for sports balls. Look for a manufacturer with a proven track record and expertise in producing sports balls through rubber molding.

2. Check the certifications and standards followed by the manufacturer. Make sure they adhere to industry-specific quality and safety standards to ensure the production of reliable and high-performance sports balls.

3. Evaluate their production capabilities, including the availability of advanced machinery, mold design expertise, and quality control measures. A manufacturer equipped with modern technology can deliver superior products.

4. Ask for samples or references to assess the quality of their sports balls. This will give you firsthand experience of their manufacturing capabilities and the quality of the final products.

5. Consider their responsiveness and customer service. Look for a manufacturer that values communication and provides prompt assistance, ensuring a smooth production process and timely delivery of sports balls.

By following these guidelines, you can choose a reputable rubber molding manufacturer who can shape materials into high-quality sports balls that meet your specific requirements.

Frequently Asked Questions

1. What is rubber molding?

Rubber molding is a process in which raw materials, such as rubber, are shaped and formed into various products using molds or dies. It is commonly used in the manufacturing of sports balls like footballs, basketballs, and soccer balls.

2. How does rubber molding work?

During rubber molding, the raw rubber material is heated and then placed into a mold or die. The mold is then closed, and pressure is applied to shape the rubber into the desired form. The rubber is then cooled and removed from the mold, resulting in the final product.

3. What are the advantages of rubber molding for sports balls?

Rubber molding offers several advantages for sports balls. It allows for precise control over the shape and size of the balls, ensuring consistent performance. The process also enables manufacturers to create durable and long-lasting balls that can withstand the rigors of sports activities.

4. What types of rubber are used in the molding process?

The type of rubber used in the molding process depends on the specific requirements of the sports ball. Common types of rubber include natural rubber, synthetic rubber, and blends of the two. Each type of rubber has its own unique properties and benefits.

5. Can rubber molding be used for customized sports balls?

Yes, rubber molding is highly adaptable and can be used to create customized sports balls. Manufacturers can easily modify the mold design to incorporate specific features, logos, or designs requested by customers.

6. Is rubber molding a cost-effective manufacturing method?

Yes, rubber molding is generally a cost-effective manufacturing method. The process allows for efficient production, minimizing waste and reducing production time. Additionally, the durability of rubber-molded sports balls often translates into cost savings in terms of product lifespan.

7. Are rubber-molded sports balls safe to play with?

Yes, rubber-molded sports balls are generally safe to play with. The molding process ensures that the balls meet stringent quality standards and undergo rigorous testing to ensure they meet safety requirements. However, it is always important to follow proper usage guidelines and take necessary precautions while playing any sport.

8. Can rubber molding be used for other applications besides sports balls?

Yes, rubber molding is a versatile process that can be used for various applications beyond sports balls. It is commonly employed in the production of automotive parts, seals, gaskets, and a wide range of industrial products.

9. How does rubber molding compare to other manufacturing methods?

Rubber molding offers unique advantages over other manufacturing methods. It allows for complex shapes and intricate designs to be produced with precision and consistency. It also enables the production of large quantities of products in a shorter time frame compared to other methods like hand molding.

10. What should I look for in a rubber molding manufacturer for sports balls?

When choosing a rubber molding manufacturer for sports balls, it is important to consider their experience, expertise, and track record in the industry. Look for a manufacturer with a proven ability to produce high-quality products, meet specific customization requirements, and adhere to safety standards.

Final Thoughts

Rubber molding plays a vital role in shaping materials into sports balls, providing us with the perfect tools to enjoy our favorite athletic activities. Whether it’s a football, basketball, or soccer ball, the precise and efficient process of rubber molding ensures that these balls offer the required durability, performance, and safety. Through customization options, manufacturers can cater to diverse preferences, allowing athletes and enthusiasts to feel a personal connection with their chosen sports equipment.

As technology advances, the future of rubber molding looks promising. Innovations in materials and manufacturing techniques will likely result in further improvements in the quality and performance of sports balls. Whether it’s for professional leagues or casual games, rubber molding continues to shape the world of sports, enabling athletes to reach new heights and pushing the boundaries of what is possible on the field or court.