Foam Core Balls: Innovations in Manufacturing

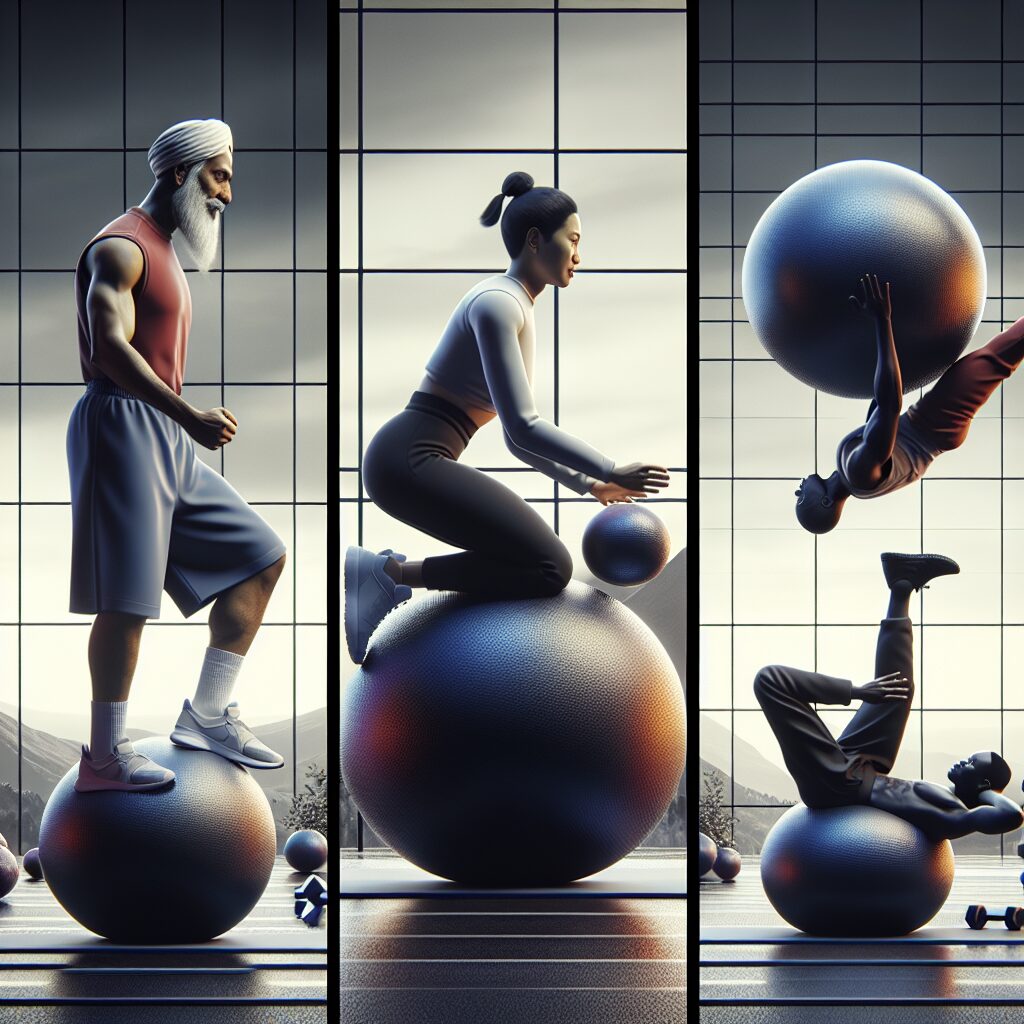

Foam core balls, also known as foam-filled balls, are spherical objects used in various recreational activities, sports, and children’s toys. These balls are made by encasing a lightweight foam core with a durable outer material, resulting in a soft and safe playing experience. One unique feature of foam core balls is their ability to provide a cushioning effect upon impact, reducing the risk of injuries during intense physical activities. This innovative manufacturing technique has revolutionized the production of balls across different industries and has significantly enhanced the quality and safety of ball-exploring-the-origins-and-uses-of-this-unique-sports-equipment/” title=”Mush Ball: Exploring the Origins and Uses of this Unique Sports Equipment”>sports equipment.

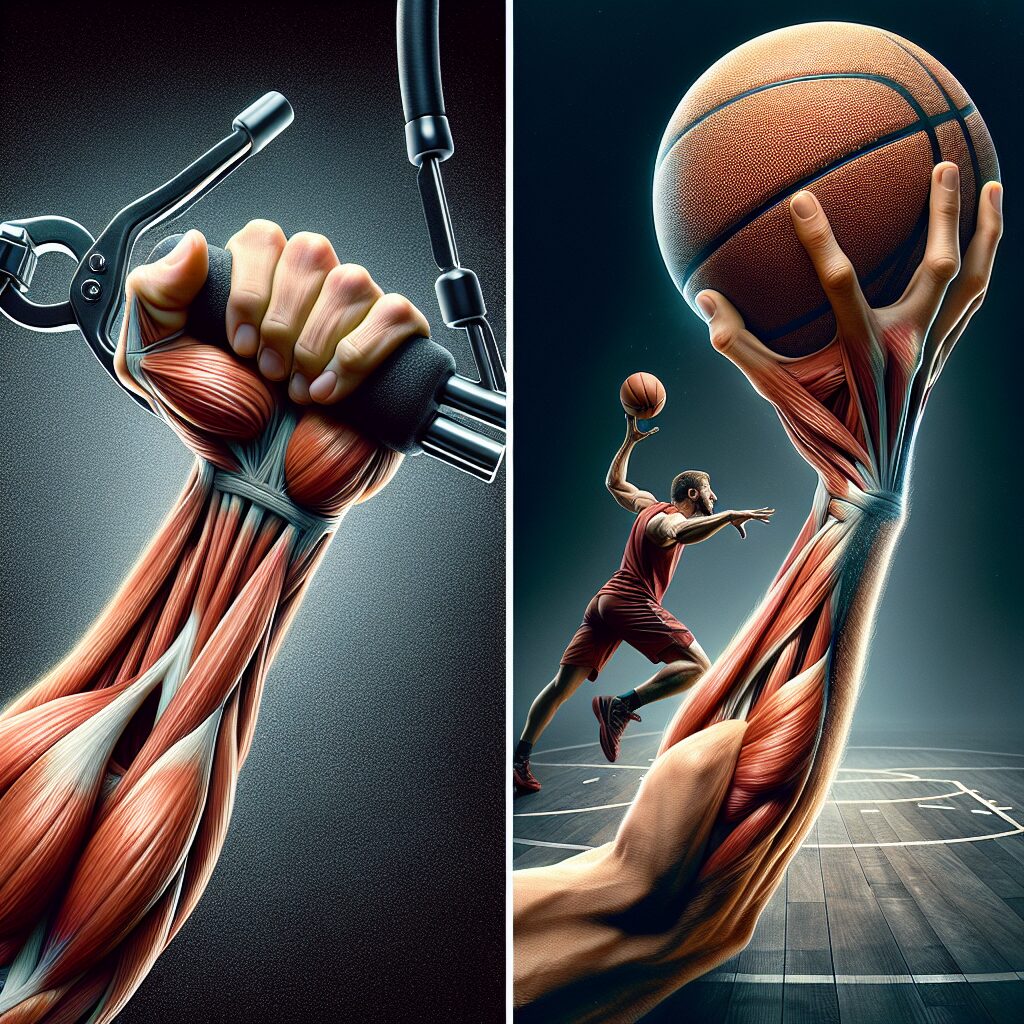

In addition to their enhanced safety features, foam core balls have also impacted the overall performance and durability of these objects. The foam filling inside the balls not only provides a soft feel but also adds weight, allowing for better control and accuracy during throws and kicks. Moreover, the foam core acts as a shock absorber, minimizing the bounce of the ball and providing a consistent bounce height, making them suitable for multiple sports and recreational activities. With their increased durability and resilience, foam core balls have become a popular choice among athletes, coaches, and recreational players alike.

In the following sections, we will delve into the key takeaways of foam core balls. We will explore the benefits they offer in terms of safety, performance, and cost-effectiveness. Moreover, we will discuss the different types of foam core balls available in the market and their applications in various sports and recreational activities. So, let’s dive in and discover why foam core balls have become a game-changer for both professionals and enthusiasts.

Key Takeaways

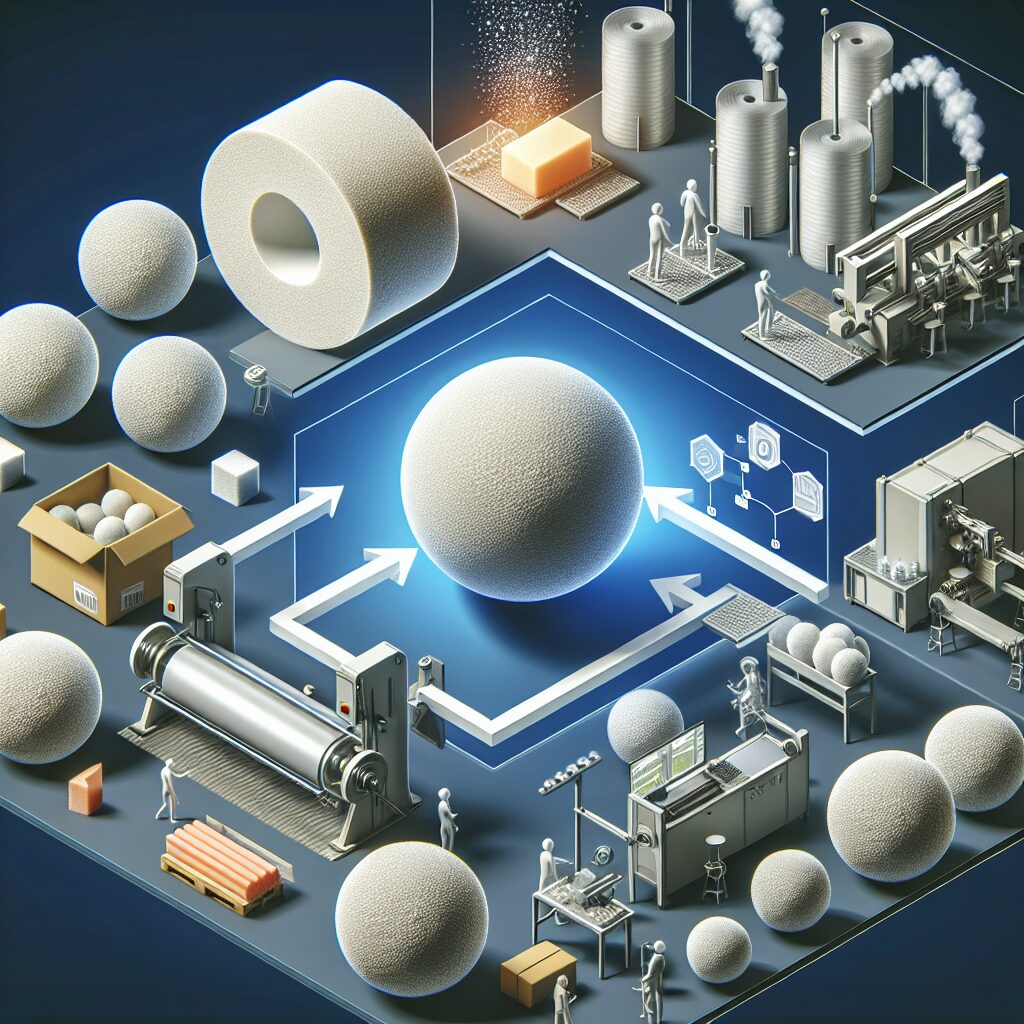

1. Foam core balls are manufactured using a unique process that combines foam molding and compression technology, resulting in a lightweight and durable product.

2. These balls are an innovative alternative to traditional rubber or plastic balls, offering better bounce, increased safety, and improved performance for various sports and recreational activities.

3. The foam core of these balls is made from high-quality polyurethane foam, providing a soft and cushioned feel, reducing the risk of injuries during play.

4. The manufacturing process allows for customization of the foam core balls with different densities, sizes, and colors, catering to specific customer requirements and preferences.

5. Foam core balls have gained popularity among sports enthusiasts, schools, and recreational facilities due to their superior quality, affordability, and versatility in a wide range of applications.

What are the latest innovations in manufacturing Foam Core Balls?

Introduction

Foam core balls have gained immense popularity in various industries due to their versatility and lightweight properties. In recent years, manufacturers have been actively pursuing innovative techniques to enhance the production process and improve the overall quality of foam core balls. This article dives deep into the latest advancements in manufacturing foam core balls, exploring various aspects that contribute to their manufacturing process.

Advanced Materials Composition

The production of foam core balls begins with the selection of suitable materials. Manufacturers are constantly researching and experimenting with advanced polymer compositions to develop foam core balls with superior durability and performance. The use of high-quality materials ensures that the balls maintain their shape, bounce, and surface texture even after prolonged use. These innovations in material composition also contribute to increased resistance against abrasion, impact, and environmental conditions.

Precision Mold Design and Injection Techniques

Precision mold design plays a crucial role in achieving consistent and accurate foam core ball production. Manufacturers employ cutting-edge technologies to design molds that provide precise dimensions, surface details, and weight distribution. Additionally, advanced injection techniques, such as gas-assisted injection molding, help create hollow sections within the foam core balls, resulting in enhanced lightweight properties without compromising structural integrity.

Automation and Robotics in Production

To maximize efficiency and reduce production time, manufacturers have integrated automation and robotics into their foam core ball manufacturing processes. Automated machinery and robots significantly streamline various manufacturing stages, such as material dispensing, mold filling, curing, and quality control. With increased automation, manufacturers can produce foam core balls at a faster rate, ensuring consistent quality and minimizing human errors.

Enhanced Surface Treatment and Finishing

Surface treatment and finishing techniques have also witnessed advancements in foam core ball manufacturing. Manufacturers have developed innovative methods to improve grip, friction, and durability of the ball’s surface. This includes the application of specialized coatings, texturizing techniques, and patterned designs. These surface treatments not only enhance the performance of foam core balls but also provide visual appeal and branding opportunities.

Sustainable Manufacturing Practices

In recent years, the foam core ball industry has shown an increased focus on sustainability in manufacturing practices. Manufacturers are adopting eco-friendly manufacturing processes, utilizing recyclable materials, and reducing energy consumption during production. By integrating sustainable practices into foam core ball manufacturing, the industry aims to minimize its environmental footprint and contribute to a greener future.

Growing Applications and Industries

Foam core balls are finding diverse applications across multiple industries. From sports and recreation to educational and promotional purposes, these innovative products are gaining traction. Foam core balls are extensively used in sports training, physical therapy, theater productions, and advertising campaigns. As industries discover the benefits and versatility of foam core balls, the demand for innovative manufacturing techniques continues to rise.

Guides for Manufacturing Foam Core Balls:

- How to select the ideal material composition for foam core balls?

- What are the key considerations for precision mold design in foam core ball manufacturing?

- What are the benefits of integrating automation and robotics into the production of foam core balls?

- How to enhance surface treatment and finishing techniques for improved foam core ball performance?

- What sustainable manufacturing practices can be implemented in foam core ball production?

- What are the emerging applications and industries for foam core balls?

- Which quality control measures should be implemented to ensure consistent foam core ball production?

Frequently Asked Questions

1. How are foam core balls manufactured?

Foam core balls are manufactured through a complex process that involves injecting expanding foam into a mold. This foam expands to fill the mold, creating a solid foam core. The core is then coated with a durable outer layer to enhance its strength and durability.

2. What materials are used in the manufacturing of foam core balls?

The materials used in the manufacturing of foam core balls include a foam core made of expanded polystyrene (EPS) or polyurethane foam. The outer coating is typically made of a durable material like polyurethane or PVC.

3. Are foam core balls safe for children?

Yes, foam core balls are considered safe for children. The foam material used in their construction is lightweight and soft, reducing the risk of injuries during play. Additionally, the outer coating provides a protective layer that enhances their durability and safety.

4. Can foam core balls be used for outdoor play?

Yes, foam core balls are suitable for both indoor and outdoor play. The durable outer coating helps to withstand outdoor conditions, including sunlight and occasional moisture, without compromising their quality or performance.

5. Are foam core balls suitable for various sports and recreational activities?

Absolutely! Foam core balls are versatile and can be used in a wide range of activities, including sports like soccer, basketball, and volleyball. They are also great for recreational games and can be used to develop motor skills and hand-eye coordination in children.

6. Are foam core balls available in different sizes?

Yes, foam core balls are available in various sizes to cater to different needs. Whether you require a small foam core ball for indoor play or a larger one for an outdoor sport, you can find options that suit your requirements.

7. Can foam core balls be customized with logos or designs?

Absolutely! Many manufacturers offer customization options for foam core balls. You can have your logo, team name, or any design printed or embossed on the outer layer of the balls, making them ideal for promotional events or team sports.

8. How durable are foam core balls?

Foam core balls are designed to be durable and withstand regular use. The outer coating provides protection against impacts and abrasion, ensuring a longer lifespan. However, excessive rough play or exposure to sharp objects may lead to damage, as with any sports equipment.

9. Can foam core balls be easily cleaned?

Yes, foam core balls are relatively easy to clean. Most can be wiped down with a damp cloth to remove dirt and stains. However, it is important to follow the manufacturer’s instructions for cleaning, as some specific products or coatings may have additional cleaning requirements.

10. Are foam core balls environmentally friendly?

Foam core balls, particularly those made with expanded polystyrene, are recyclable. However, it is essential to dispose of them correctly to ensure they are recycled or repurposed ethically. Check with local recycling facilities to ensure proper disposal methods for foam core balls.

Final Thoughts

Foam core balls have revolutionized the world of sports and recreational activities. Their innovative manufacturing process and versatile design make them a popular choice for both children and adults. With their lightweight and soft foam core, coupled with a durable outer coating, foam core balls provide a safe and enjoyable playing experience while improving hand-eye coordination and motor skills. Their customization options and availability in various sizes make them suitable for a wide range of activities and events.

Furthermore, the durability and ease of maintenance of foam core balls ensure they can withstand regular use in both indoor and outdoor environments. Whether it’s for team sports, individual training, or organized games, foam core balls are an excellent choice. Additionally, the eco-friendly nature of foam core balls, with some being recyclable, contributes to a more sustainable approach to sports equipment manufacturing. As more innovations continue to emerge in foam core ball manufacturing, the possibilities for creating enhanced playing experiences and promoting a healthier and greener planet are endless.